What is Thin Aluminum Foil? Thin aluminum foil is a very thin aluminum material, usually between 0.006mm and 0.2mm. Thin aluminum foil can be manufactured through a process of rolling and stretching, which allows it to be very thin without sacrificing strength and durability. It also has some other advantages such as high electrical conductivity, thermal insulation, corrosion resistance, easy cleaning, etc. ...

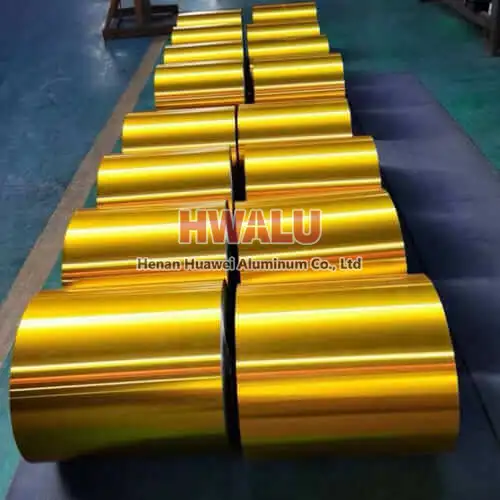

Black Gold Aluminum foil Black Gold Aluminum foil refers to aluminum foil with black or gold spray coating on the surface, and also has one side of gold and one side of very colored aluminum foil. Black aluminum foil is mostly used in aluminum foil tape, air duct materials, etc. Gold aluminum foil is widely used and is often used in chocolate packaging, pharmaceutical packaging, aluminum foil lunch box ...

What is aluminum foil jumbo roll? Aluminum foil jumbo roll refers to a wide continuous aluminum foil roll, usually with a width of more than 200mm. It is made of aluminum alloy material through rolling, cutting, grinding and other processes. Aluminum foil jumbo roll has the advantages of lightweight, strong plasticity, waterproof, corrosion resistance, heat insulation, etc., so it is widely used in many field ...

Introduction Of Best Price Aluminium Foil Roll 3003 Aluminium foil roll 3003 is a common product of Al-Mn series alloys. Because of the addition of alloy Mn element, it has excellent rust resistance, weldability and corrosion resistance. Main tempers for Aluminium foil roll 3003 are H18, H22 and H24. Similarly, 3003 aluminum foil is also a non-heat treated alloy, so a cold working method is used to improv ...

Know more about medicine aluminum foil Medicine Aluminum Foil is a special-purpose aluminum foil that is usually used for packaging pharmaceuticals. The raw material is also aluminum foil alloy. After treatment, its properties are very different from other types of aluminum foil, and it can be well applied to the pharmaceutical industry. Medicine aluminum foil material properties Aluminum foil used for pha ...

0.03mm thick aluminum foil, which is very thin, has a variety of potential uses due to its properties. Some common applications of 0.03mm thick aluminum foil include: 1. Packaging: This thin aluminum foil is often used for packaging purposes such as wrapping food items, covering containers, and protecting products from moisture, light, and contaminants. 2. Insulation: It can be used as a thin layer of insul ...

Aluminum foil lunch box is a new type of non-toxic and environmentally friendly tableware. 1. The main ingredient in the aluminum foil lunch box is aluminum, so it will react with acid like aluminum cans, and the salt produced by aluminum and organic acids will react with gastric acid to produce aluminum chloride, so we need to use it. Note that, generally speaking, it is often used for steaming rice. There is ...

Aluminum foil lunch boxes made of aluminum foil can be processed into various shapes and are widely used in food packaging such as pastry baking, airline catering, takeaway, cooked food, instant noodles, instant lunch and other food fields. The aluminum foil lunch box has a clean appearance and good thermal conductivity. It can be heated directly on the original packaging with ovens, microwave ovens, steamers and ...

Aluminum foil is a good packaging material, which can be used as food packaging, pharmaceutical packaging, and can also be used as a yogurt lid on yogurt. And aluminum foil is a common material choice for yogurt lids. The production process of aluminum foil for yogurt lid: Aluminum foil: Choose high-quality aluminum foil suitable for food packaging. It should be clean, free of any contaminants, and the cover sh ...

Food packaging aluminum foil is related to human health and safety, and is usually produced with specific specifications and characteristics to ensure its suitability for the food industry. The following are some common specifications of aluminum foil for food packaging: Food packaging foil alloy types: Aluminum foil used for food packaging is usually made from 1xxx, 3xxx or 8xxx series alloys. Common alloys in ...

After printing and coating, aluminum foil paper and cash register paper need to be post-printed and slit on a slitting machine to cut large rolls of semi-finished products into the required specifications. The semi-finished products that run on the slitting machine are an unwinding and rewinding. This process includes two parts: machine speed control and tension control. The so-called tension is to pull the al ...