Aluminum Foil

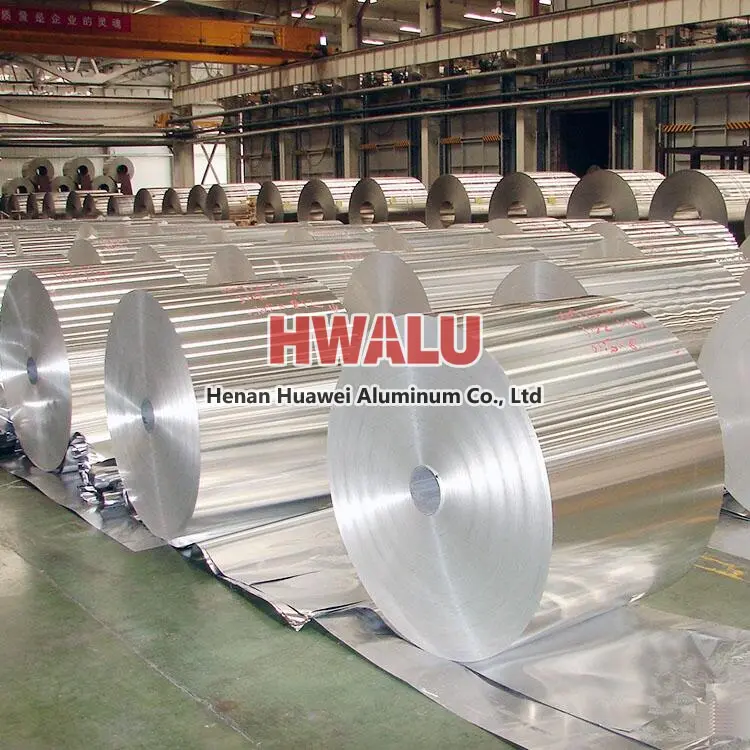

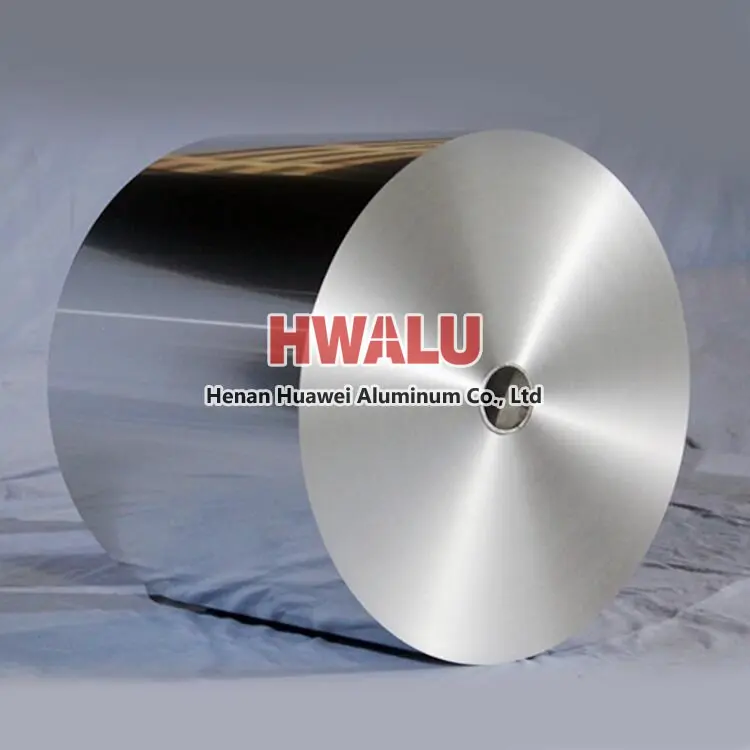

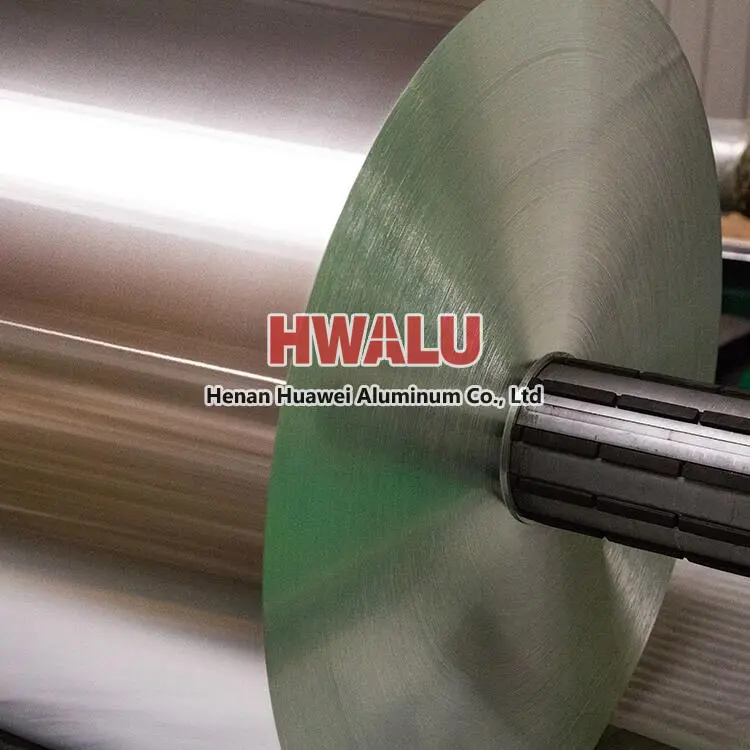

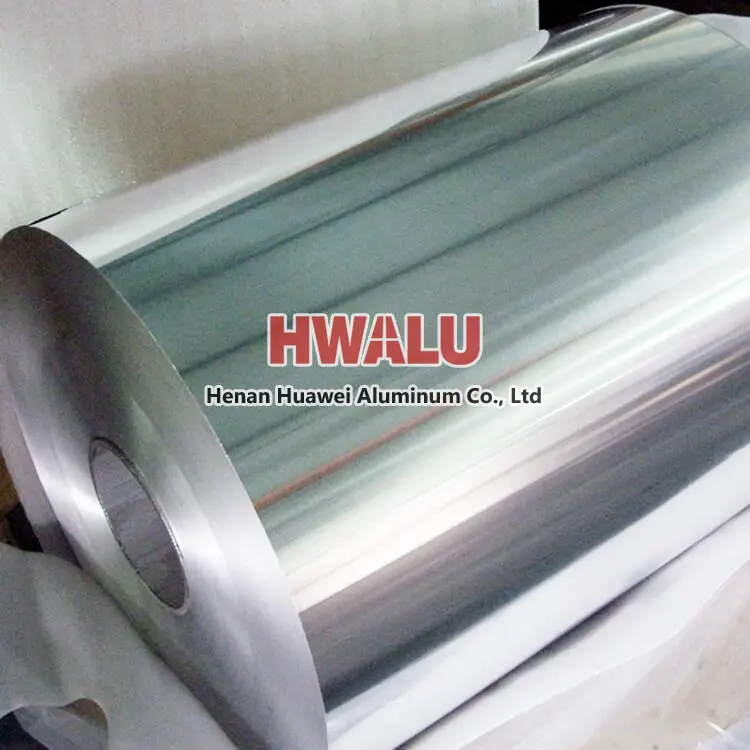

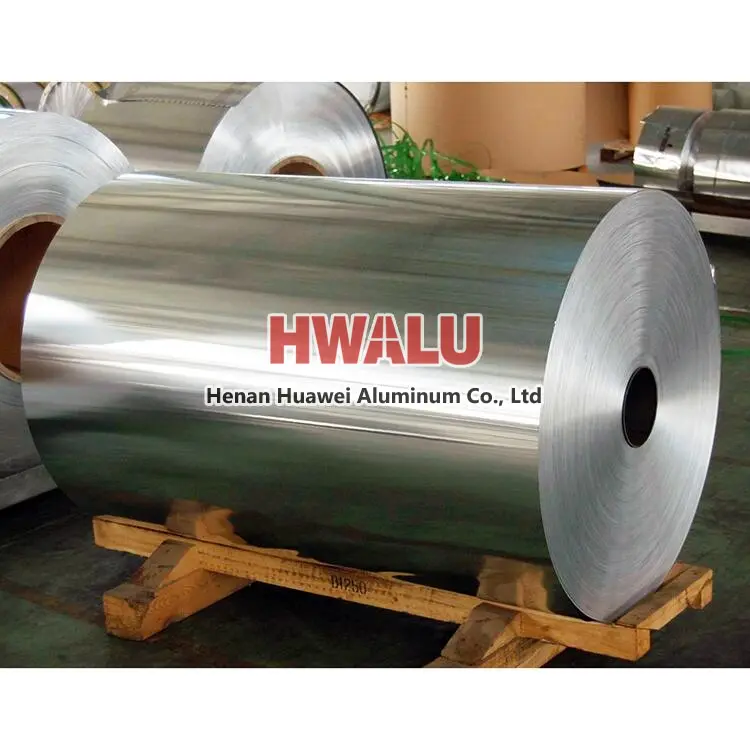

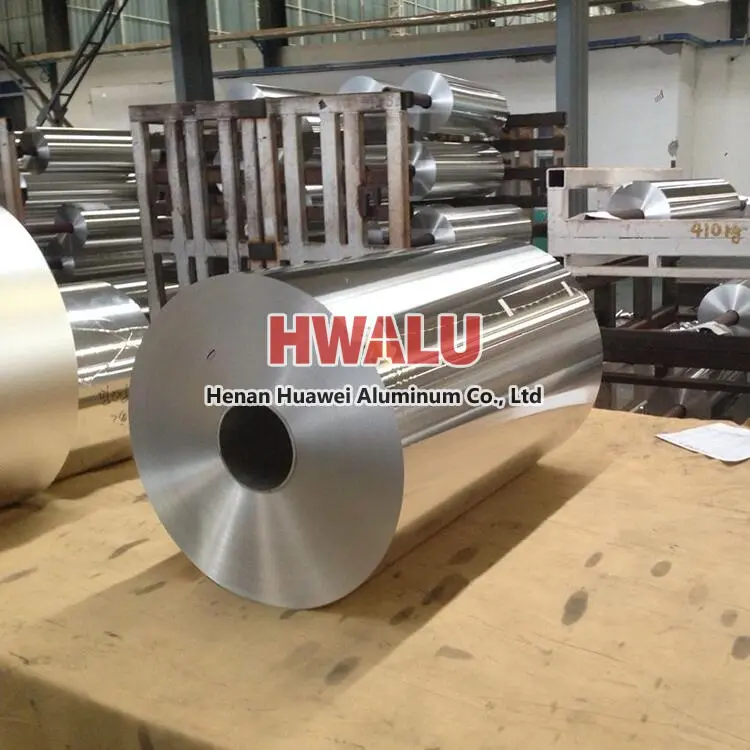

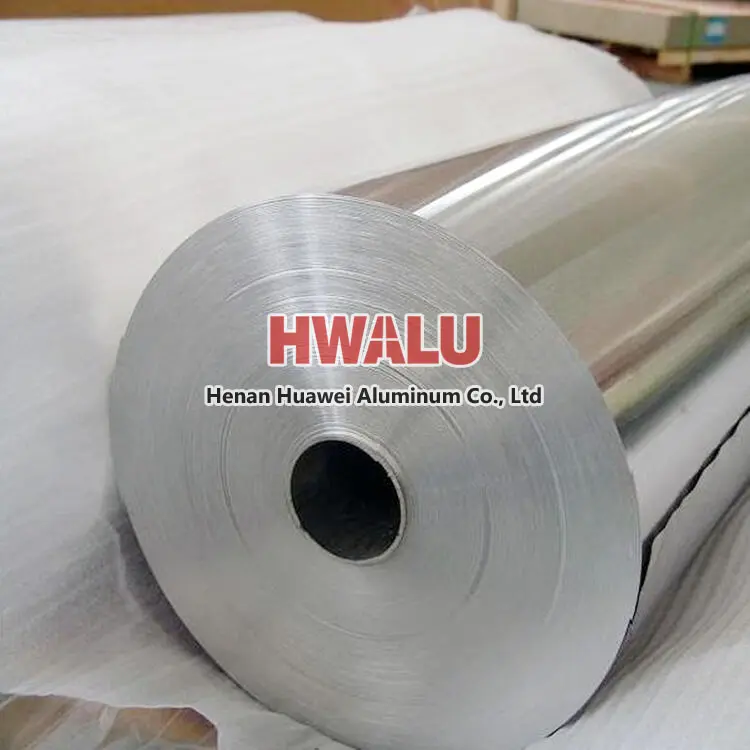

We supply aluminum foil jumbo roll material with thickness of 0.0045mm – 0.2mm and width of 80mm – 1400mm.

Alloys include 1235, 8011, 8079 etc.

Inner diamter of the roll are 76mm and 152mm.

Aluminum foil are widely used in household, kithcen, packaging materials industry, food containers, composite materials, electrical products, architectural decoration, air-conditioning manufacturing, printing and other fields.

Hot Products

Henan Huawei Aluminum Co., Ltd

Professional service and good quality products.

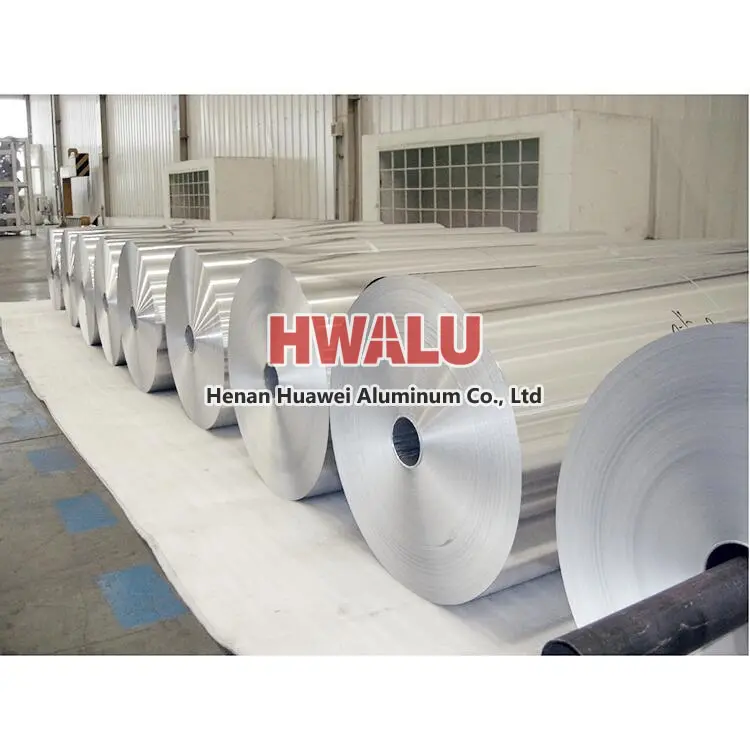

Henan Huawei Aluminum Co., Ltd (HWALU for short), a privately-owned enterprises established in 2001, is located in Huiguo Town which is the famous Aluminum Capital in Henan Province, China. There are 1,200 employees including a R&D team with 26 specialists, and covers an area of 250,000 square meters. It’s a professional manufacturer and engages in the research, development, production, sales and service of aluminum foil.

The International trade department began the export business on 2012, with the sales about 12 and annual export about 80000 tons.

With the accumulation for more than 9 years, HWALU has established its Brand abroad. At the present stage, we aim at develop more market, with the good quality, service.

We can produce aluminum products by customer’s requirements, and our products mainly includes aluminum sheet, aluminum coil, aluminum foil, aluminum strip, round aluminum circle, aluminum tread plate, embossed aluminum, mirror aluminum, anodized aluminum, color coated aluminum, heat transfer plates, and other aluminum machining parts, aluminum bilister foil etc

News

Which 8000 series alloy is more suitable for alu alu foil? For alu alu foil, aluminum foil for pharmaceutical packaging, the selection of the base material needs to take into account factors such as the barrier properties, mechanical strength, processing performance and cost of the aluminum foil. The aluminum foil base material should have excellent moisture barrier, air barrier, light-shielding properties, and ...

Anodized Aluminum Foil Overview Anodized aluminum foil is aluminum foil that has been anodized. Anodizing is an electrochemical process in which aluminum foil is immersed in an electrolyte solution and an electric current is applied. This causes oxygen ions to bond with the aluminum surface, forming a layer of aluminum oxide. It can increase the thickness of the natural oxide layer on the aluminum surface. This ...

Aluminum foil and aluminum coil are both versatile aluminum alloy materials used in different applications across various industries. Aluminum coil alloy and aluminum foil alloy have similar properties in many aspects, but also have many different characteristics. Huawei will make a detailed comparison between the two in terms of properties, uses, etc.: What are aluminum coils and aluminum foil? Aluminum Foil: ...

Aluminum foil is a good packaging material, which can be used as food packaging, pharmaceutical packaging, and can also be used as a yogurt lid on yogurt. And aluminum foil is a common material choice for yogurt lids. The production process of aluminum foil for yogurt lid: Aluminum foil: Choose high-quality aluminum foil suitable for food packaging. It should be clean, free of any contaminants, and the cover sh ...

Lunch boxes are essential packaging boxes in the food packaging industry. Common lunch box packaging materials on the market include plastic lunch boxes, aluminum foil lunch boxes, etc. Among them, aluminum foil lunch boxes are more commonly used. For lunch box packaging, aluminum foil is widely used due to its excellent barrier properties, flexibility and lightness. What aluminum foil alloy is most suitable for ...

Aluminum foil plays a vital role in the construction of lithium-ion batteries. There are many models in the 1000-8000 series alloys that can be used in battery production. Pure aluminum foil: Pure aluminum foil commonly used in lithium batteries includes various alloy grades such as 1060, 1050, 1145, and 1235. These foils are usually in different states such as O, H14, H18, H24, H22. Especially alloy 1145. ...