What is Aluminum Foil for Pans Aluminum foil for pans is usually thicker and stronger than typical kitchen foil to withstand high heat and stress. Aluminum foil for pans can be used to cover the bottom of pans to keep food from sticking to them, and to make liners for steamers and bakeware to prevent food from sticking to the bottom or to the pan. The use of aluminum foil for pans is similar to that of ordina ...

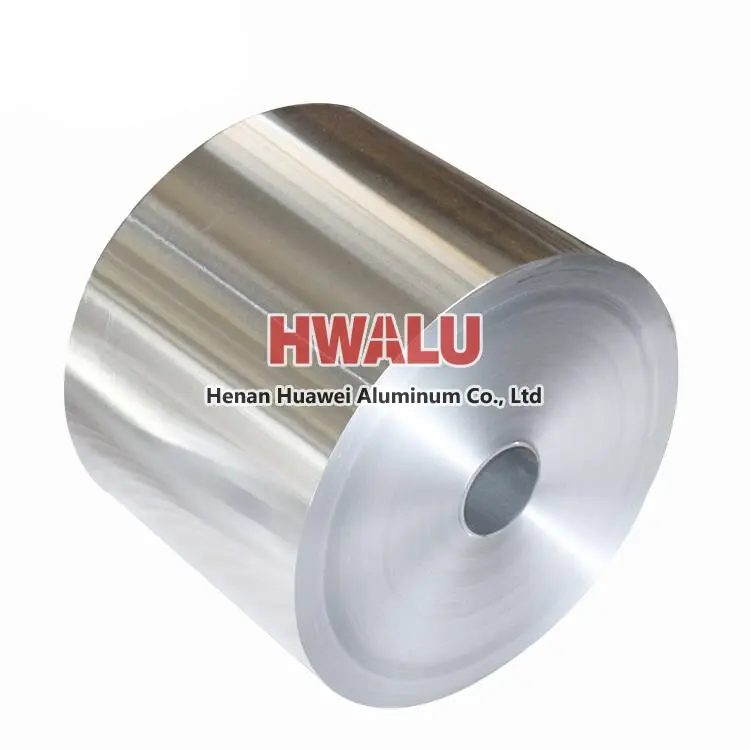

What is aluminum foil jumbo roll? Aluminum foil jumbo roll refers to a wide continuous aluminum foil roll, usually with a width of more than 200mm. It is made of aluminum alloy material through rolling, cutting, grinding and other processes. Aluminum foil jumbo roll has the advantages of lightweight, strong plasticity, waterproof, corrosion resistance, heat insulation, etc., so it is widely used in many field ...

Welcome to Huawei Aluminum, your trusted partner in the world of aluminum foil. We are a leading aluminum foil 8011 12-micron factory and wholesaler, committed to delivering high-quality products that cater to a wide range of industries. In this comprehensive guide, we will explore everything you need to know about our Aluminum Foil 8011, its specifications, and applications. 1. Introduction to Aluminum Foil ...

What is Extra-heavy duty aluminum foil Extra-heavy duty aluminum foil is a type of aluminum foil that is thicker and more durable than standard or heavy-duty aluminum foil. It is designed to withstand higher temperatures and provide extra strength, making it suitable for more demanding applications in the kitchen and beyond. Extra-heavy duty aluminum foil common alloys The common alloy used for extra-heavy ...

Double zero aluminum foil refers to aluminum foil with a thickness between 0.001mm ( 1 micron ) and 0.01mm ( 10 micron ). Such as 0.001mm ( 1 micron ), 0.002mm ( 2 micron ), 0.003mm ( 3 micron ), 0.004mm ( 4 micron ), 0.005mm ( 5 micron ), 0.006mm ( 6 micron ), 0.007mm ( 7 micron ), 0.008mm ( 8 micron ), 0.009mm ( 9 micron ) 0.005 mic aluminium foil Advantages of 0.001-0.01 micron aluminum foil An ...

What is Aluminum Foil for Pans? Aluminum foil for pans is a type of aluminum foil specially used for cooking, and it is usually thicker and stronger than ordinary household aluminum foil, and has better heat resistance properties. It is often used to cover the bottom or sides of pans to prevent food from sticking to or scorching, while also helping to maintain moisture and nutrients in food. Aluminium foil ...

Coiling defects mainly refer to loose, layer channeling, tower shape, warping and so on. Aluminum foil roll during the winding process. Because the tension of aluminum foil is limited, enough tension is the condition to form a certain tension gradient. Therefore, the winding quality ultimately depends on good shape, reasonable process parameters and suitable precision sleeve. It is ideal to obtain tight coils ...

Aluminum foil has the following advantages in food packaging: Barrier property. Aluminum foil has excellent resistance to water, air (oxygen), light, and microorganisms, which are important factors in food spoilage. Therefore, aluminum foil has a good protective effect on food. Easy processing. Aluminum has a low melting point, good heat sealing, and easy molding. Can be processed into any shape according to ...

Product name: industrial aluminum foil roll Item Specification (mm) Description ALUMINUM FOIL ROLLS WITH SUPPORT FOR INDUSTRIAL USE 8011-O, 0. 014 (+/-4%) *300 (+/-1mm). Outside -matt Inside - bright ID 152 OD min 450, Max 600. Elongation - min 2% Tensile strength - min 80, max 130MPa. Porosity - max 30 pcs per 1m2. Wettability - A. Splices - maximum 1 splice per ...

1060 aluminum foil is a common type of 1000 series aluminum alloy products. It is a high-purity aluminum foil with an aluminum content of at least 99.6%. This type of aluminum foil has many advantages and is suitable for home use. 1060 aluminum foil can be used well for household aluminum foil packaging. Performance advantages of 1060 alloy as household foil: 1. Good corrosion resistance: 1060 aluminum foil ...

Is the aluminum foil in the oven toxic? Please pay attention to the difference between the oven and the microwave. They have different heating principles and different utensils. The oven is usually heated by electric heating wires or electric heating pipes. Microwave ovens rely on microwaves to heat. The oven heating tube is a heating element that can heat the air and food in the oven after the oven is pow ...

I can't believe that there are 20 uses for aluminum foil! ! ! Aluminum foil is a widely used material. Aluminum foil has a wide range of uses in daily life and industrial applications due to its light weight, good processing performance, high reflectivity, high temperature resistance, moisture resistance, corrosion resistance and other characteristics. Here are twenty uses of aluminum foil: 1. Alumin ...