What is aluminium foil 11 micron? 11 micron aluminum foil refers to a thin sheet of aluminum that is approximately 11 microns (μm) thick. The term "micron" is a unit of length equal to one millionth of a meter. Aluminum foil 11 micron, also known as 0.0011mm aluminum foil, is a multifunctional material with excellent barrier properties, flexibility and conductivity. Aluminum foil thickness application Aluminu ...

what is 1100 alloy aluminum foil 1100 alloy aluminum foil is a type of aluminum foil made from 99% pure aluminum. It is commonly used in various applications such as packaging, insulation, and electronics because of its excellent corrosion resistance, high thermal conductivity, and good electrical conductivity. 1100 alloy aluminum foil is soft and ductile, making it easy to work with and shape. It can be easi ...

Why does hair use aluminum foil? The use of aluminum foil for hair is often done during hair coloring, especially when a specific pattern or effect is desired. Aluminum foil can help isolate and hold the hair dye in place, ensuring it only goes where it's needed, creating a more precise and detailed finish. When coloring hair, hairdressers usually divide the hair to be colored into sections and wrap each sect ...

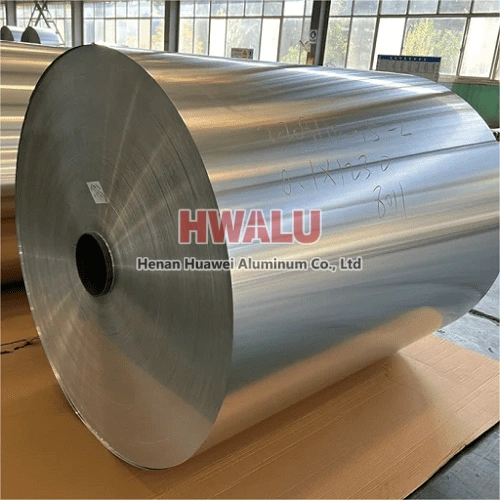

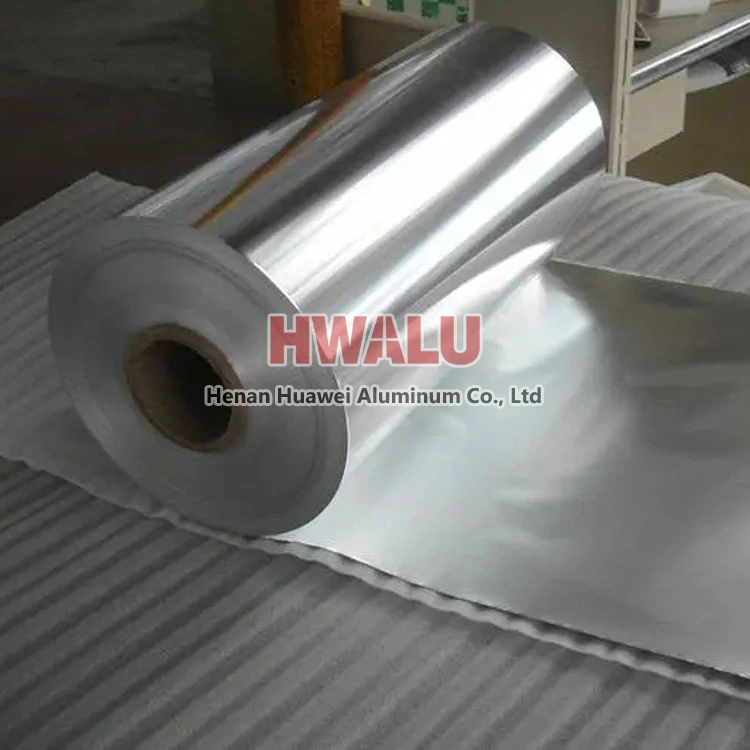

What is aluminum foil jumbo roll? Aluminum foil jumbo roll refers to a wide continuous aluminum foil roll, usually with a width of more than 200mm. It is made of aluminum alloy material through rolling, cutting, grinding and other processes. Aluminum foil jumbo roll has the advantages of lightweight, strong plasticity, waterproof, corrosion resistance, heat insulation, etc., so it is widely used in many field ...

what is 8021 alloy aluminum foil? 8021 alloy aluminum foil has excellent moisture resistance, shading, and extremely high barrier ability: elongation, puncture resistance, and strong sealing performance. The aluminum foil after compounding, printing, and gluing is widely used as a packaging material. Mainly used for food packaging, blister drug packaging, soft battery packs, etc. The Advantages Of 8021 a ...

Aluminum foil plays a vital role in the construction of lithium-ion batteries. There are many models in the 1000-8000 series alloys that can be used in battery production. Pure aluminum foil: Pure aluminum foil commonly used in lithium batteries includes various alloy grades such as 1060, 1050, 1145, and 1235. These foils are usually in different states such as O, H14, H18, H24, H22. Especially alloy 1145. ...

Food packaging aluminum foil is related to human health and safety, and is usually produced with specific specifications and characteristics to ensure its suitability for the food industry. The following are some common specifications of aluminum foil for food packaging: Food packaging foil alloy types: Aluminum foil used for food packaging is usually made from 1xxx, 3xxx or 8xxx series alloys. Common alloys in ...

Only China, the United States, Japan and Germany can produce double zero foils with a thickness of 0.0046mm in the world. From a technical point of view, it is not difficult to produce such thin foils, but it is not easy to efficiently produce high-quality double-zero foils on a large scale. At present, many enterprises in my country can realize the commercial production of double zero foil, mainly including: ...

Aluminum foil rolling produces plastic deformation under the conditions of roll-free rolling. At this time, the rolling mill frame is elastically deformed and the rolls are elastically flattened. When the thickness of the rolled piece reaches a smaller and more limited thickness h. When the rolling pressure has no effect, it is very difficult to make the rolled piece thinner. Usually two pieces of aluminum foi ...

1. Wide moisture-proof waterproof: Aluminum foil tape has the performance of moisture-proof, waterproof, oxidation, etc., which can effectively protect the adhesive items and prevent them from being eroded by moisture and water vapor. 2. Innidity insulation: Aluminum foil tape has good thermal insulation performance, can effectively prevent heat transmission and is suitable for thermal insulation of pipelines, ...

▌ Make bananas last longer Like avocados, bananas can go from underripe to overripe in the blink of an eye. This is because bananas release a gas called ethylene to ripen, and the stem is where the most ethylene is released. One way to prevent bananas from ripening too quickly is to wrap a small piece of aluminum foil around the stem. ▌ Polishing chrome with aluminum foil It can be used in places ...