Aluminum foil for packaging bag introduction Aluminum foil bags are also called aluminum foil bags or aluminum foil packaging bags. Because aluminum foil has excellent barrier properties and protective capabilities, it is widely used to package a variety of products. These foil bags are commonly used to preserve the freshness, flavor and quality of food, pharmaceuticals, chemicals and other sensitive items. ...

What is aluminum foil for cable? The outer surface of the cable needs to be wrapped with a layer of aluminum foil for protection and shielding. This kind of aluminum foil is usually made of 1145 grade industrial pure aluminum. After continuous casting and rolling, cold rolling, slitting and complete annealing, it is divided into small coils according to the length required by the user and supplied to the cable f ...

Introduction: At Huawei Aluminum, we take pride in being a leading manufacturer and wholesaler of high-quality aluminum foil paper designed specifically for food containers. With a commitment to excellence and precision, our 3003 Aluminum foil is engineered to meet the highest industry standards, ensuring the safety and reliability of your food packaging. Why Choose 3003 Aluminum for Food Containers? The c ...

what is 1100 alloy aluminum foil 1100 alloy aluminum foil is a type of aluminum foil made from 99% pure aluminum. It is commonly used in various applications such as packaging, insulation, and electronics because of its excellent corrosion resistance, high thermal conductivity, and good electrical conductivity. 1100 alloy aluminum foil is soft and ductile, making it easy to work with and shape. It can be easi ...

Introduction of 8006 alloy aluminum foil 8006 alloy aluminum foil is a non-heat treatable aluminum alloy. The 8006 aluminum foil product has a bright surface and is degreasing clean. Especially suitable for making wrinkle-free lunch boxes. Huawei Aluminum's 8006 aluminum foil adopts hot rolling method, and the tensile strength is between 123-135Mpa. Aluminum 8006 alloy composition 8006 aluminum alloy is an ...

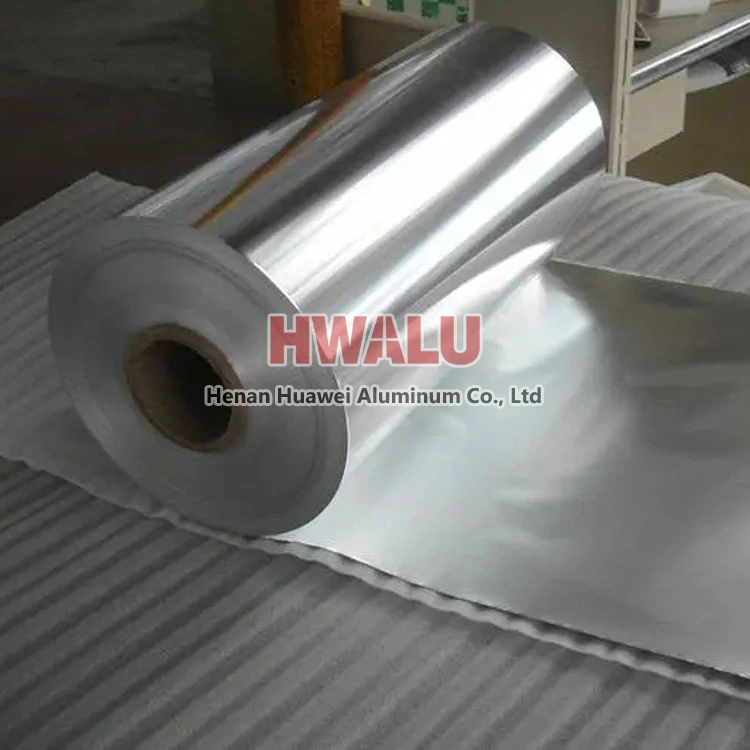

What is aluminum foil for foil board Aluminum foil for foil board refers to a special type of aluminum foil used to make foil board, also known as "foil material". Foil sheets are commonly used to package food and pharmaceuticals to protect them from air, moisture, odours, light and other external elements. Aluminum foil for foil boards is usually thicker than regular aluminum foil, usually between 0.2-0.3 mm ...

1-Moisture-proof and anti-oxidation: Aluminum foil paper can effectively prevent food from getting wet and oxidized and cause deterioration, so as to maintain the freshness and taste of food. 2-Thermal insulation: The thermal conductivity of aluminum foil paper is very low, which can effectively insulate heat and prevent heat loss. 3-Blocking UV rays: Aluminum foil can effectively block UV rays and protect ...

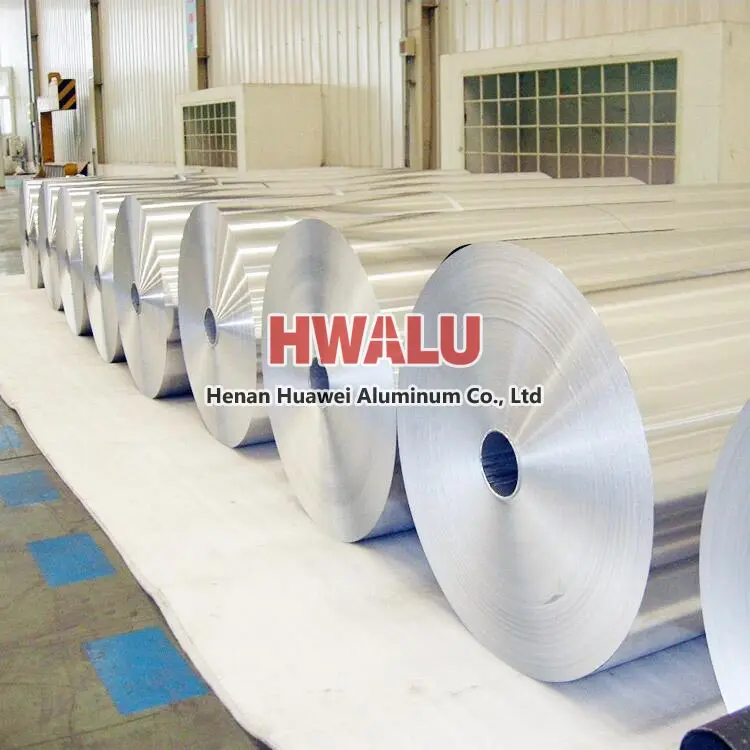

Foil winding, aluminum foil to be tensioned, in order to maintain a certain tension, smooth, flat winding coil, the thicker the aluminum foil requires greater tension, the maximum tension of the coil winding machine is limited, exceeding the maximum tension of the machine is dangerous, the tension is too small winding coil loose, can not ensure the size requirements. Therefore, here is not to say that you want to ...

As a metal material, aluminum foil is non-toxic, tasteless, has excellent electrical conductivity and light-shielding properties, extremely high moisture resistance, gas barrier properties, and its barrier performance is incomparable and irreplaceable by any other polymer materials and vapor-deposited films. of. Perhaps it is precisely because aluminum foil is a metal material completely different from plastic, i ...

Why Can Aluminum Foil Conduct Electricity? Do you know how aluminum foil conducts electricity? Aluminum foil is a good conductor of electricity because it is made of aluminum, which has a high electrical conductivity. Electrical conductivity is the measure of how well a material conducts electricity. Materials with high electrical conductivity allow electricity to flow through them easily because they have many ...

1. Uncoated aluminum foil Uncoated aluminum foil refers to aluminum foil that has been rolled and annealed without any form of surface treatment. In my country 10 years ago, the aluminum foil used for air-conditioning heat exchangers in foreign countries about 15 years ago was all uncoated aluminum foil. Even at present, about 50% of the heat exchange fins used in foreign developed countries are still uncoated ...

Pre-coated aluminum foil used for punching various containers, commonly used alloy 8011, 3003, 3004, 1145, etc., thickness is 0.02-0.08mm. Oiling thickness is 150-400mg/m². The use of aluminum foil as a semi-rigid container to hold food has been widely adopted at home and abroad. With the continuous development of the national economy and the continuous improvement of people’s living standards, people’s health ...