What is aluminum foil for food Aluminum foil for food is a type of aluminum foil that is specifically designed and manufactured for use in food preparation, cooking, storage, and transport. It is commonly used in households and food service industries to wrap, cover, and store food items, as well as to line baking sheets and pans. Aluminum foil for food is available in various sizes, thicknesses, and strength ...

what is 1100 alloy aluminum foil 1100 alloy aluminum foil is a type of aluminum foil made from 99% pure aluminum. It is commonly used in various applications such as packaging, insulation, and electronics because of its excellent corrosion resistance, high thermal conductivity, and good electrical conductivity. 1100 alloy aluminum foil is soft and ductile, making it easy to work with and shape. It can be easi ...

What is 13 micron aluminum foil? "Aluminum Foil 13 Micron" is a thin and light aluminum foil that falls within the thickness range of household aluminum foil and is commonly used for various packaging and insulation purposes. It is a very common thickness specification. 13 micron aluminum foil equivalent name 13μm aluminum foil 0.013mm aluminum foil Household packaging aluminum foil 13 micron aluminum foil ...

what is Cold forming alu alu foil? Cold forming blister foil can absolutely resist vapor, oxygen and UV rays with good performance of aroma barrier. Each blister is a single protection unit, no effect to barrier after opening first cavity. Cold forming foil is suitable to pack drugs that easy to be affected in wet regions and tropics. It can be shaped in various appearance by changing stamping mold. Simultane ...

what is Pure aluminum foil? Aluminum that is 99% pure or higher is called pure aluminum. Primary aluminium, the metal produced in an electrolysis furnace, contains a series of "impurities". However, in general, only iron and silicon elements exceed 0.01%. For foils larger than 0.030 mm (30µm), the most common aluminum alloy is en aw-1050: pure aluminium foil with at least 99.5% aluminium. (Aluminum larger tha ...

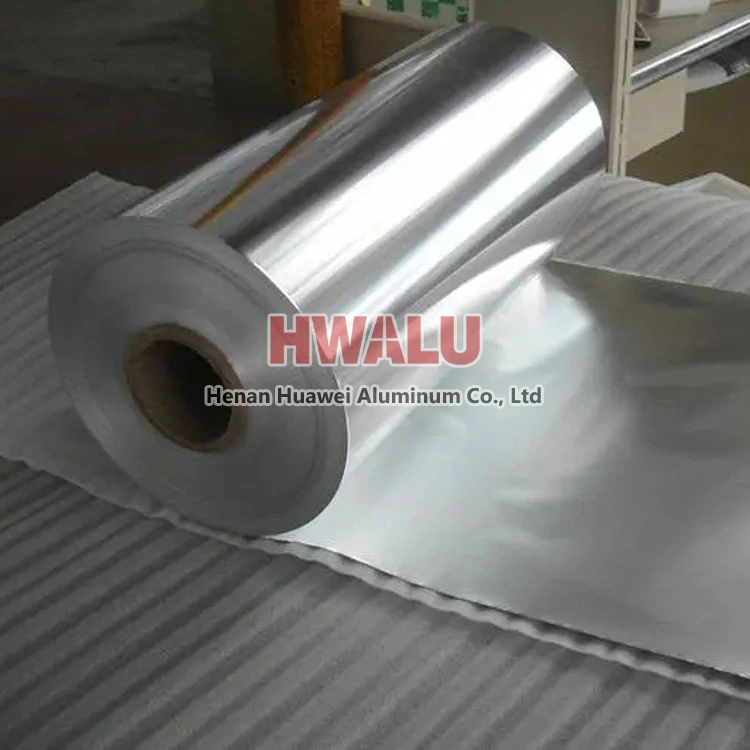

what is Industrial Aluminum Foil? Industrial aluminum foil is a kind of aluminium foil material used in industrial production, which is usually thicker and wider than ordinary household aluminium foil, and is more suitable for harsh industrial environments such as high temperatures and high pressure. Industrial size aluminium foil has good electrical conductivity, thermal conductivity, and corrosion resistanc ...

As a metal material, aluminum foil is non-toxic, tasteless, has excellent electrical conductivity and light-shielding properties, extremely high moisture resistance, gas barrier properties, and its barrier performance is incomparable and irreplaceable by any other polymer materials and vapor-deposited films. of. Perhaps it is precisely because aluminum foil is a metal material completely different from plastic, i ...

Aluminum foil is recyclable. Due to the high purity of aluminum foil materials, they can be reprocessed into various aluminum products after recycling, such as food packaging, construction materials, etc. Recycling aluminum, meanwhile, is an energy-saving process that involves melting down aluminum scrap to create new aluminum products. Compared to producing aluminum from raw materials, the recycling process of a ...

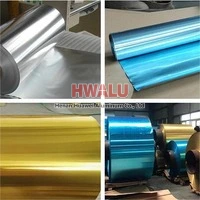

Anodized Aluminum Foil Overview Anodized aluminum foil is aluminum foil that has been anodized. Anodizing is an electrochemical process in which aluminum foil is immersed in an electrolyte solution and an electric current is applied. This causes oxygen ions to bond with the aluminum surface, forming a layer of aluminum oxide. It can increase the thickness of the natural oxide layer on the aluminum surface. This ...

1. Uncoated aluminum foil Uncoated aluminum foil refers to aluminum foil that has been rolled and annealed without any form of surface treatment. In my country 10 years ago, the aluminum foil used for air-conditioning heat exchangers in foreign countries about 15 years ago was all uncoated aluminum foil. Even at present, about 50% of the heat exchange fins used in foreign developed countries are still uncoated ...

The selection principle of pass processing rate is as follows: (1) Under the premise that the equipment capacity allows the rolling oil to have good lubrication and cooling performance, and can obtain good surface quality and shape quality, the plasticity of the rolled metal should be fully utilized, and the large pass processing rate should be used as much as possible to improve the rolling mill Production ef ...

Is the aluminum foil in the oven toxic? Please pay attention to the difference between the oven and the microwave. They have different heating principles and different utensils. The oven is usually heated by electric heating wires or electric heating pipes. Microwave ovens rely on microwaves to heat. The oven heating tube is a heating element that can heat the air and food in the oven after the oven is pow ...