Alloy parameters of aluminum foil for cups Aluminium foil for cups is usually made of aluminium alloy materials with good processability and corrosion resistance, mainly including 8000 series and 3000 series. --3003 aluminum alloy Alloy composition Al 96.8% - 99.5%, Mn 1.0% - 1.5% Physical properties density 2.73g/cm³, thermal expansion coefficient 23.1×10^-6/K, thermal conductivity 125 W/(m K), e ...

Introduction of 8006 alloy aluminum foil 8006 alloy aluminum foil is a non-heat treatable aluminum alloy. The 8006 aluminum foil product has a bright surface and is degreasing clean. Especially suitable for making wrinkle-free lunch boxes. Huawei Aluminum's 8006 aluminum foil adopts hot rolling method, and the tensile strength is between 123-135Mpa. Technical parameters of aluminum foil 8006 Alloy 8 ...

What is aluminium foil 11 micron? 11 micron aluminum foil refers to a thin sheet of aluminum that is approximately 11 microns (μm) thick. The term "micron" is a unit of length equal to one millionth of a meter. Aluminum foil 11 micron, also known as 0.0011mm aluminum foil, is a multifunctional material with excellent barrier properties, flexibility and conductivity. Aluminum foil thickness application Aluminu ...

Introduction: Welcome to Huawei Aluminum, your trusted source for high-quality Air-conditioner Aluminum Foil. This webpage will provide you with in-depth information about our aluminum foil products, including alloy models, specifications, and the reasons to choose Huawei Aluminum for your air-conditioning projects. What is Air-conditioner Aluminum Foil? Air-conditioner aluminum f ...

Introduction of 8079 alloy aluminum foil What is aluminum foil grade 8079? 8079 alloy aluminum foil usually used to produce kinds of aluminum alloy foil, which offers the best properties for many applications with H14, H18 and other tempers and thicknesses between 10 and 200 microns. The tensile strength and elongation of alloy 8079 are higher than other alloys, so it is not flexible and moisture resistant. ...

Aluminum foil parameters Raw Material 1235, 3003, 8011 etc Alloy Temper O, H28, etc Thickness 6.5 micron, 10 microns, 11micron( 11 microns), 20micron, 130-250mic ( for laminated foil cold forming ) Size 3000m, 80 cm, etc We can provide jumbo roll aluminum foil Product Name Alloy Temper Thickness or Gauge(mm ) Width(mm ) Surface Finishing Use Aluminum Foil For Foo ...

What is the density of aluminum foil alloy? Aluminum foil is a hot stamping material that is directly rolled into sheets of metallic aluminum. Because the hot stamping effect of aluminum foil is similar to that of pure silver foil, aluminum foil is also called fake silver foil. Aluminum foil is soft, malleable, and has a silvery white luster. It also has a lighter texture, thanks to the lower density of aluminum ...

1. Chemical composition: The alloy grades of aluminum foil for heat exchange fins mainly include 1100, 1200, 8011, 8006, etc. From the perspective of use, air conditioners do not have strict requirements on the chemical composition of aluminum heat exchange fins. Without surface treatment, 3A21 aluminum alloy has relatively good corrosion resistance, high mechanical properties such as strength and elongation, ...

Product name: 8011 aluminum foil roll ID: 76MM, MAX ROLL WEIGHT: 55kg ITEM SPECIFICATION (MM) ALLOY / TEMPER 1 0.015*120 8011 O 2 0.012*120 8011 O 3 0.015*130 8011 O 4 0.015*150 8011 O ID: 76MM, MAX ROLL WEIGHT: 100 kg 5 0.015*200 8011 O

Aluminum foil jumbo roll: Ideal for cooking or baking large dishes such as roasts, turkeys or baked cakes as it covers the entire dish with ease. Ideal for wrapping leftovers or storing food in the freezer, as you can cut the desired length of foil as needed. Aluminum foil jumbo rolls can last for a long time, which can save costs in long-term use. Small rolls of aluminum foil: More portable an ...

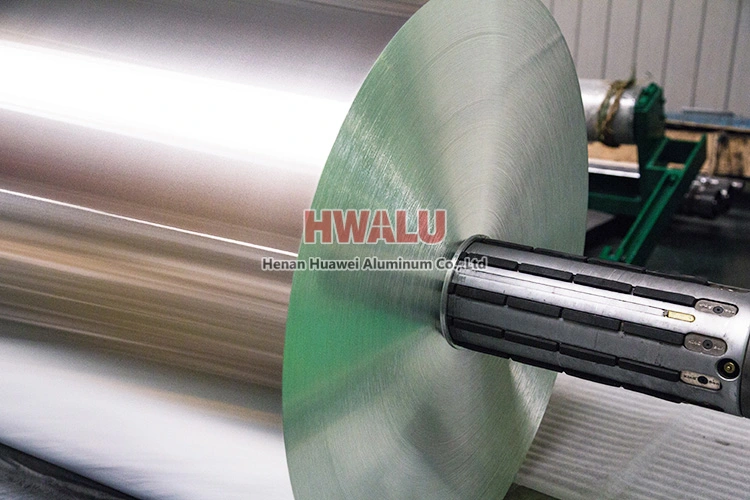

In the production of double foil, the rolling of aluminum foil is divided into three processes: rough rolling, intermediate rolling, and finishing rolling. From a technological point of view, it can be roughly divided from the thickness of the rolling exit. The general method is that the exit thickness is greater than Or equal to 0.05mm is rough rolling, the exit thickness is between 0.013 and 0.05 is intermediat ...

The thickness of aluminum foil for food packaging is generally between 0.015-0.03 mm. The exact thickness of aluminum foil you choose depends on the type of food being packaged and the desired shelf life. For food that needs to be stored for a long time, it is recommended to choose thicker aluminum foil, such as 0.02-0.03 mm, to provide better protection against oxygen, water, moisture and ultraviolet rays, th ...