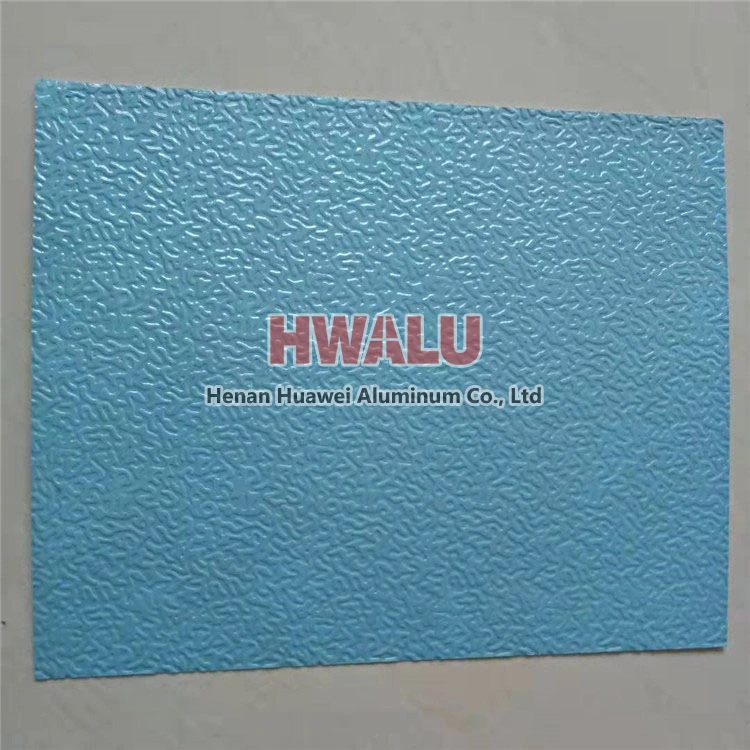

Specifications of sarin coated embossed aluminum foil Alloy model 1100 or 1200 3003 or 3004 5052, 5083, 5754 8011, 8079 Thickness 0.006mm-0.2mm Width 200mm-1600mm Flower type Common flower types include five flowers, tiger skin, pearl and so on. Coating sarin coating, color: gold, silver, red, green, blue, etc. Paper core inner diameter 76mm or 152mm Packing method w ...

1235 aluminum foil for battery 1235 aluminum foil is an aluminum alloy foil with a higher content in the 1000 series. It is a high-quality aluminum alloy material that can be widely used in many fields. It can be widely used in food foil packaging and medicinal foil packaging. It can also be used in for battery packaging. Battery foil 1235 element content Alloy Si Fe Cu Mn Mg Cr Ni Zn V Ti ...

What is Thin Aluminum Foil? Thin aluminum foil is a very thin aluminum material, usually between 0.006mm and 0.2mm. Thin aluminum foil can be manufactured through a process of rolling and stretching, which allows it to be very thin without sacrificing strength and durability. It also has some other advantages such as high electrical conductivity, thermal insulation, corrosion resistance, easy cleaning, etc. ...

6 mic aluminum foil brief overview 6 mic aluminum foil is one of the very commonly used light gauge aluminum foil.6 mic are equal to 0.006 millimeters, known as double zero six aluminum foil in China. aluminum mic 6 properties Tensile Strength: 48 ksi (330 MPa) Yield Strength: 36 ksi (250 MPa) Hardness: 70-80 Brinell Machinability: Easy to process due to its homogeneity and low in ...

leading manufacturer and wholesaler of high-quality 1200 Aluminum Foil At Huawei Aluminum, we take pride in being a leading manufacturer and wholesaler of high-quality 1200 Aluminum Foil. With a rich history of delivering top-notch products to our global clientele, we are committed to excellence in both quality and service. Explore our comprehensive range of 1200 Aluminum Foil, where precision meets purity. ...

0.03mm thick aluminum foil, which is very thin, has a variety of potential uses due to its properties. Some common applications of 0.03mm thick aluminum foil include: 1. Packaging: This thin aluminum foil is often used for packaging purposes such as wrapping food items, covering containers, and protecting products from moisture, light, and contaminants. 2. Insulation: It can be used as a thin layer of insul ...

1) Surface treatment (chemical etching, electrochemical etching, DC anodizing, corona treatment); 2) Conductive coating (surface coating carbon, graphene coating, carbon nanotube coating, composite coating); 3) 3D porous structure (foam structure, nanobelt structure, nano cone mechanism, fiber weaving mechanism); 4) Composite modification treatment. Among them, carbon coating on the surface is a commo ...

Extra-wide aluminum foil serves several purposes and finds applications in various industries. Here are some common uses for extra-wide aluminum foil: Extra wide aluminum foil for Industrial Insulation: Extra-wide aluminum foil is often used for insulation in industrial settings. It is effective in reflecting radiant heat, making it suitable for insulating large areas in construction, manufacturing, and oth ...

Melting Point Of Aluminum Foil Do you know what melting point is? Melting point, also known as the melting temperature of a substance, is a physical property of a substance. Melting point refers to the temperature at which a solid substance changes into a liquid state. At this temperature, the solid begins to melt, and the arrangement of its internal molecules or atoms changes significantly, causing the subst ...

In the production process of aluminum foil, there are multiple processes such as rolling, finishing, annealing, packaging, etc. The interlocking production process, any problem in any link may cause aluminum foil quality problems. The quality defects of the purchased aluminum foil products will not only affect the appearance, but also directly affect the quality of the products produced, and even more directly ca ...

The most commonly used aluminum foil alloy in food packaging applications is 8011. Aluminum alloy 8011 is a typical alloy of aluminum foil and has become the industry standard for food packaging due to its excellent properties. Here are some reasons why alloy 8011 is ideal for food packaging: Good Barrier Performance: The aluminum foil made of 8011 alloy can effectively block moisture, oxygen and light, helpin ...