Aluminum foil for disposable tableware Today, with the rapid economic development and the continuous improvement of the quality of life, aluminum foil for disposable tableware is used more and more frequently in daily life. Reasons for aluminum foil for disposable tableware Aluminum foil for disposable tableware can be waterproof, maintain freshness, prevent bacteria and stains, and maintain flavor and freshne ...

Aluminum foil for flexible packaging Use 1235/1145 Aluminum foil for high temperature cooking food packaging 1235/1145 Aluminum foil for liquid food packaging 1235/1145 Aluminum foil for solid food packaging 1235/1145 Aluminum foil for pharmaceutical packaging Characteristic It has strong ductility and elongation characteristics and has good thermal stability, fewer pinholes, and good sha ...

Alloy parameters of aluminum foil for cups Aluminium foil for cups is usually made of aluminium alloy materials with good processability and corrosion resistance, mainly including 8000 series and 3000 series. --3003 aluminum alloy Alloy composition Al 96.8% - 99.5%, Mn 1.0% - 1.5% Physical properties density 2.73g/cm³, thermal expansion coefficient 23.1×10^-6/K, thermal conductivity 125 W/(m K), e ...

What is aluminum foil for pill packaging Aluminum foil for pill packaging is a kind of aluminum foil used for pharmaceutical packaging. This aluminum foil is usually very thin and has properties such as waterproof, anti-oxidation and anti-light, which can effectively protect the pills from external influences such as moisture, oxygen and light. Aluminum foil for pill packaging usually has the following advantage ...

Aluminum foil thickness for different purposes Alloy Alloy state Typical thickness(mm) Processing methods End use smoke foil 1235-O、8079-O 0.006~0.007 Composite paper, coloring, printing, etc. Used in cigarette packaging after lining, printing or painting. Flexible packaging foil 8079-O、1235-O 0.006~0.009 Composite paper, plastic film embossing, coloring, printi ...

8011 aluminum foil is a common aluminum alloy material, which has received extensive attention and application due to its good performance and wide application fields. Below, we will introduce the characteristics and advantages of 8011 aluminum foil from various aspects. First of all, 8011 aluminum foil has excellent corrosion resistance. Aluminum foil itself has good oxidation resistance, and 8011 aluminum fo ...

In the production of double foil, the rolling of aluminum foil is divided into three processes: rough rolling, intermediate rolling, and finishing rolling. From a technological point of view, it can be roughly divided from the thickness of the rolling exit. The general method is that the exit thickness is greater than Or equal to 0.05mm is rough rolling, the exit thickness is between 0.013 and 0.05 is intermediat ...

Oven bottom: Do not spread aluminum foil on the bottom of the oven. This could cause the oven to overheat and cause a fire. Use with acidic foods: Aluminum foil should not come in contact with acidic foods such as lemons, tomatoes, or other acidic foods. These foods can dissolve the aluminum foil, increasing the aluminum content of the food. Bake Clean Oven Racks: Aluminum foil should not be used to cov ...

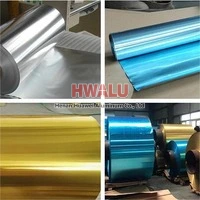

Anodized Aluminum Foil Overview Anodized aluminum foil is aluminum foil that has been anodized. Anodizing is an electrochemical process in which aluminum foil is immersed in an electrolyte solution and an electric current is applied. This causes oxygen ions to bond with the aluminum surface, forming a layer of aluminum oxide. It can increase the thickness of the natural oxide layer on the aluminum surface. This ...

The main factors affecting the heat sealing strength of aluminum foil medicine packaging are as follows: 1. Raw and auxiliary materials The original aluminum foil is the carrier of the adhesive layer, and its quality has a great influence on the heat seal strength of the product. In particular, oil stains on the surface of the original aluminum foil will weaken the adhesion between the adhesive and the orig ...

The thickness of aluminum foil for food packaging is generally between 0.015-0.03 mm. The exact thickness of aluminum foil you choose depends on the type of food being packaged and the desired shelf life. For food that needs to be stored for a long time, it is recommended to choose thicker aluminum foil, such as 0.02-0.03 mm, to provide better protection against oxygen, water, moisture and ultraviolet rays, th ...