aluminium foil specification Aluminum foil for coated foil Coated Products gauges/thicknesses 0.00035” - .010” Coating thicknesses .002″ Width .250” - 54.50” Length customize aluminum foil for coated foil We offer a variety of Coated Products Carbon coated aluminum foil Heat Seals Corrosion Resistant Epoxies Slip Lubes Print Primers Release Coatings, ...

Aluminum foil parameters Raw Material 1235, 3003, 8011 etc Alloy Temper O, H28, etc Thickness 6.5 micron, 10 microns, 11micron( 11 microns), 20micron, 130-250mic ( for laminated foil cold forming ) Size 3000m, 80 cm, etc We can provide jumbo roll aluminum foil Product Name Alloy Temper Thickness or Gauge(mm ) Width(mm ) Surface Finishing Use Aluminum Foil For Foo ...

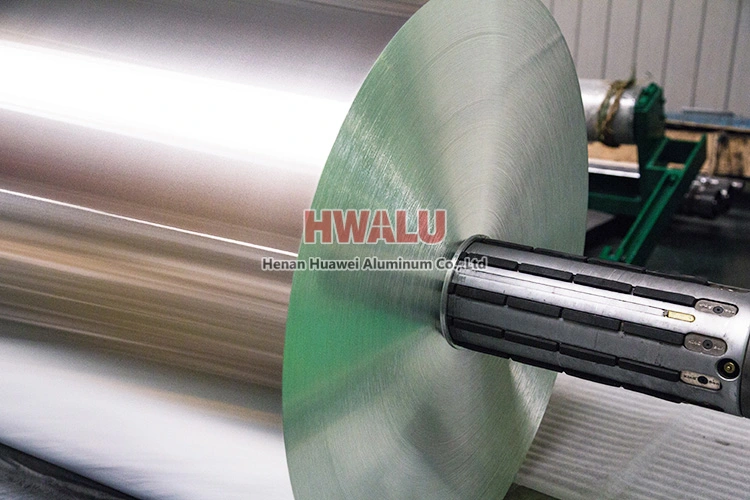

Huawei Aluminum: Your Trusted Source for 50 Micron Aluminum Foil Welcome to Huawei Aluminum, your one-stop destination for high-quality 50 micron aluminum foil. We are a renowned aluminum foil factory and wholesaler, specializing in manufacturing and distributing a wide range of aluminum foil products. With a commitment to excellence and a focus on meeting the unique needs of our customers, we have established o ...

Introduction of 8006 alloy aluminum foil 8006 alloy aluminum foil is a non-heat treatable aluminum alloy. The 8006 aluminum foil product has a bright surface and is degreasing clean. Especially suitable for making wrinkle-free lunch boxes. Huawei Aluminum's 8006 aluminum foil adopts hot rolling method, and the tensile strength is between 123-135Mpa. Technical parameters of aluminum foil 8006 Alloy 8 ...

What is aluminum foil for bowls Aluminum foil for bowls refers to a kind of aluminum foil material used to cover food in bowls. It's usually a sheet of aluminum foil that wraps easily around the bowl and keeps food fresh and warm. Aluminum foil for bowls is commonly used for storing and heating food and can be used in the microwave or oven. There are multiple benefits to using aluminum foil for bowls, it can ...

Air conditioner aluminum foil Air-conditioning is indispensable to escape the heat in summer. As air-conditioning enters thousands of households, it is also constantly developing. At present, air conditioners are gradually developing in the direction of miniaturization, high efficiency, and long life. The air-conditioning heat exchange fins are also correspondingly developed in the direction of ultra-thin and hi ...

Now the aluminum foil we see in the market is no longer made of tin, because it is more expensive and less durable than aluminum. The original tin foil (also known as tin foil) is really made of tin. Tin foil is softer than aluminum foil. It will smell tinted to wrap food. At the same time, tin foil cannot be heated due to its low melting point, or the heating temperature is high-such as 160 It begins to becom ...

Have you ever eaten grilled fish or sixty-six, and you must have seen this tin foil, but have you seen this thing used in indoor spaces? That's right it's called decorative foil (decorative tin foil). Generally, it can be used on walls, top cabinets, or art installations. Aluminum foil (tinfoil paper) can be kneaded out of wrinkles, resulting in a very unique and abstract reflective texture, and the appeara ...

Beer caps can be packed in aluminum foil. Aluminum foil is a commonly used packaging material due to its excellent barrier properties, protecting contents from light, moisture and external contaminants. It helps maintain the freshness and quality of the product. Beer caps are small, lightweight and can be easily wrapped or packaged in aluminum foil. There are several reasons for doing this, including: 1 ...

Oven bottom: Do not spread aluminum foil on the bottom of the oven. This could cause the oven to overheat and cause a fire. Use with acidic foods: Aluminum foil should not come in contact with acidic foods such as lemons, tomatoes, or other acidic foods. These foods can dissolve the aluminum foil, increasing the aluminum content of the food. Bake Clean Oven Racks: Aluminum foil should not be used to cov ...

The rolling oil and other oil stains remaining on the surface of the foil, which are formed on the foil surface to varying degrees after annealing, are called oil spots. The main reasons for oil spots: high degree of oil in aluminum foil rolling, or inappropriate distillation range of rolling oil; mechanical oil infiltration in aluminum foil rolling oil; improper annealing process; excessive oil on the surface ...

Product name: 8011 aluminum foil roll ID: 76MM, MAX ROLL WEIGHT: 55kg ITEM SPECIFICATION (MM) ALLOY / TEMPER 1 0.015*120 8011 O 2 0.012*120 8011 O 3 0.015*130 8011 O 4 0.015*150 8011 O ID: 76MM, MAX ROLL WEIGHT: 100 kg 5 0.015*200 8011 O