What is cable aluminum foil? Cable aluminum foil is a special type of aluminum foil used for cable structures. It is processed from aluminum alloy raw materials through cold rolling, hot rolling and other processes. Aluminum foil used in cables has excellent electrical conductivity and good corrosion resistance, especially in the telecommunications and electrical industries, playing an important role. 8011 ...

What is aluminum foil for wrapping Aluminum foil for wrapping is a thin, flexible sheet of aluminum that is commonly used for wrapping food items or other objects for storage or transportation. It is made from a sheet of aluminum that has been rolled out to a desired thickness and then processed through a series of rollers to give it the desired strength and flexibility. Aluminum foil for wrapping is availabl ...

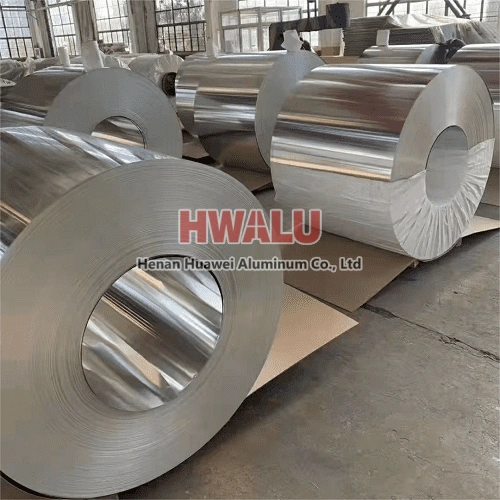

What is industrial aluminum foil roll Industrial aluminum foil rolls are jumbo aluminum foil, commonly used in various industrial applications. Industrial aluminum foil is a thin, flexible sheet made of aluminum metal, produced by rolling aluminum sheets cast from molten aluminum through a series of rolling mills to reduce thickness and create uniform specifications. Industrial aluminum foil rolls are different ...

Introduction: At Huawei Aluminum, we take pride in being a leading manufacturer and wholesaler of high-quality aluminum foil paper designed specifically for food containers. With a commitment to excellence and precision, our 3003 Aluminum foil is engineered to meet the highest industry standards, ensuring the safety and reliability of your food packaging. Why Choose 3003 Aluminum for Food Containers? The c ...

What is Aluminum Foil for Pans? Aluminum foil for pans is a type of aluminum foil specially used for cooking, and it is usually thicker and stronger than ordinary household aluminum foil, and has better heat resistance properties. It is often used to cover the bottom or sides of pans to prevent food from sticking to or scorching, while also helping to maintain moisture and nutrients in food. Aluminium foil ...

In recent years, Huawei Aluminum Co., Ltd. has set up a special research team under the condition that the aluminum foil rolling mill backing roll and the inner ring of the backing roll bearing are tight, to maintain production by repairing the scrapped backing rolls, and to ensure the normal operation of the seven aluminum foil rolling mills. During the repair process, the research team was able to repair, explo ...

The biggest feature of aluminum foil is its light weight and wide range of uses, suitable for aviation, construction, decoration, industry and other industries. Aluminum is very cost-effective, and its electrical conductivity is second only to that of copper, but the price is much cheaper than that of copper, so many people now choose aluminum as the main material for wires. 1060, 3003, 5052 are several common ...

In the production of double foil, the rolling of aluminum foil is divided into three processes: rough rolling, intermediate rolling, and finishing rolling. From a technological point of view, it can be roughly divided from the thickness of the rolling exit. The general method is that the exit thickness is greater than Or equal to 0.05mm is rough rolling, the exit thickness is between 0.013 and 0.05 is intermediat ...

Product name: industrial aluminum foil roll Item Specification (mm) Description ALUMINUM FOIL ROLLS WITH SUPPORT FOR INDUSTRIAL USE 8011-O, 0. 014 (+/-4%) *300 (+/-1mm). Outside -matt Inside - bright ID 152 OD min 450, Max 600. Elongation - min 2% Tensile strength - min 80, max 130MPa. Porosity - max 30 pcs per 1m2. Wettability - A. Splices - maximum 1 splice per ...

Aluminum foil lunch box is not a new thing, but it is really the last two or three years is particularly active. In particular, the hot sealing aluminum foil lunch box, because it is the first sealed food and then high-temperature cooking disinfection, in the consumer to open the taste before the maximum ensure food safety and health, full tightness, and high barrier can also be a good lock food flavor. Even i ...

1060 aluminum foil is a common type of 1000 series aluminum alloy products. It is a high-purity aluminum foil with an aluminum content of at least 99.6%. This type of aluminum foil has many advantages and is suitable for home use. 1060 aluminum foil can be used well for household aluminum foil packaging. Performance advantages of 1060 alloy as household foil: 1. Good corrosion resistance: 1060 aluminum foil ...