What is aluminum foil for wrapping Aluminum foil for wrapping is a thin, flexible sheet of aluminum that is commonly used for wrapping food items or other objects for storage or transportation. It is made from a sheet of aluminum that has been rolled out to a desired thickness and then processed through a series of rollers to give it the desired strength and flexibility. Aluminum foil for wrapping is availabl ...

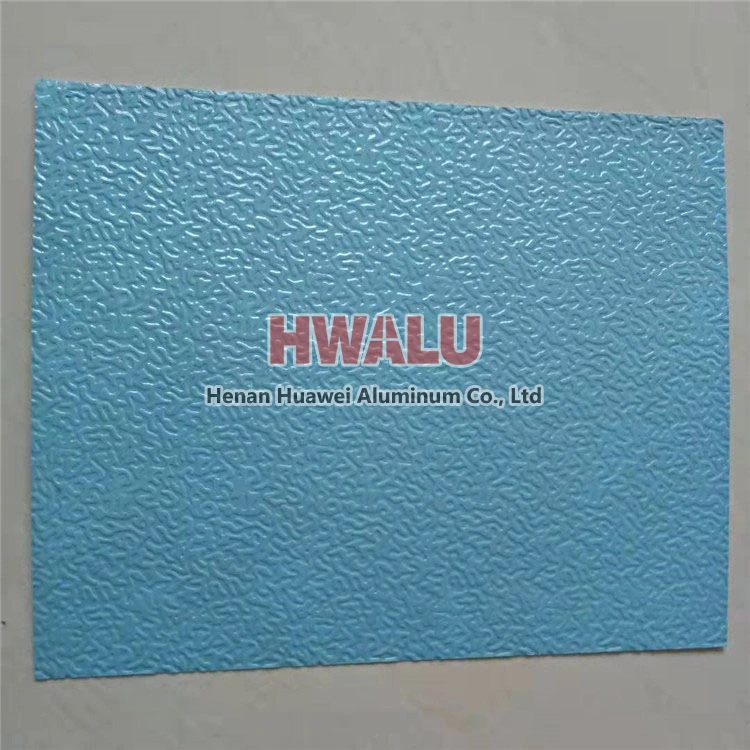

Specifications of sarin coated embossed aluminum foil Alloy model 1100 or 1200 3003 or 3004 5052, 5083, 5754 8011, 8079 Thickness 0.006mm-0.2mm Width 200mm-1600mm Flower type Common flower types include five flowers, tiger skin, pearl and so on. Coating sarin coating, color: gold, silver, red, green, blue, etc. Paper core inner diameter 76mm or 152mm Packing method w ...

What is aluminum foil for insulation? Aluminum foil for insulation is a type of aluminum foil that is used in various forms of insulation to help reduce heat loss or gain. It is a highly effective material for thermal insulation due to its low thermal emissivity and high reflectivity. Aluminum foil for insulation is commonly used in the construction industry for insulating walls, roofs, and floors of building ...

Aluminum foil for kitchen parameters Surface Teatment: One side bright, another side dull. Printing: coloured gold, rose gold Embossed: 3d pattern Thickness: 20mts, 10 mic, 15 micron etc Sizes: 1m, 40*600cm, 40x100 cm etc Characteristics and uses of kitchen aluminum foil Aluminum foil is a versatile and commonly used kitchen item that offers a range of benefits for cooking, food storage and othe ...

Aluminum foil can be customized size Thickness: 0.006mm - 0.2mm Width: 200mm - 1300mm Length: 3 m - 300 m In addition, customers can also choose different shapes, colors, printing and packaging methods according to their needs. If you need custom aluminum foil, please contact us, we can provide you with options and customized services. Aluminum foil type According to the processin ...

leading manufacturer and wholesaler of high-quality 1200 Aluminum Foil At Huawei Aluminum, we take pride in being a leading manufacturer and wholesaler of high-quality 1200 Aluminum Foil. With a rich history of delivering top-notch products to our global clientele, we are committed to excellence in both quality and service. Explore our comprehensive range of 1200 Aluminum Foil, where precision meets purity. ...

0.03mm thick aluminum foil, which is very thin, has a variety of potential uses due to its properties. Some common applications of 0.03mm thick aluminum foil include: 1. Packaging: This thin aluminum foil is often used for packaging purposes such as wrapping food items, covering containers, and protecting products from moisture, light, and contaminants. 2. Insulation: It can be used as a thin layer of insul ...

Aluminum foil is often colloquially referred to as "tin foil" due to historical reasons and similarities in appearance between the two materials. However, it's important to note that aluminum foil and tin foil are not the same thing. Here's why aluminum foil is sometimes called "tin foil": Historical Context: The term "tin foil" originated at a time when actual tin was used to create thin sheets for wrappin ...

Aluminum foil is a thin sheet of aluminum metal that has the following properties: Lightweight: Aluminum foil is very lightweight because aluminium metal itself is a lightweight material. This makes aluminum foil an ideal material during packaging and shipping. Good sealing: The surface of aluminum foil is very smooth, which can effectively prevent the penetration of oxygen, water vapor and other gases, s ...

Fire or explosion in aluminum foil rolling must meet three conditions: combustible materials, such as rolling oil, cotton yarn, hose, etc.; combustible materials, that is, oxygen in the air; fire source and high temperature, such as friction, electric sparks, static electricity, open flames, etc. . Without one of these conditions, it will not burn and explode. The oil vapor and oxygen in the air generated duri ...

▌ Make bananas last longer Like avocados, bananas can go from underripe to overripe in the blink of an eye. This is because bananas release a gas called ethylene to ripen, and the stem is where the most ethylene is released. One way to prevent bananas from ripening too quickly is to wrap a small piece of aluminum foil around the stem. ▌ Polishing chrome with aluminum foil It can be used in places ...

Beer caps can be packed in aluminum foil. Aluminum foil is a commonly used packaging material due to its excellent barrier properties, protecting contents from light, moisture and external contaminants. It helps maintain the freshness and quality of the product. Beer caps are small, lightweight and can be easily wrapped or packaged in aluminum foil. There are several reasons for doing this, including: 1 ...