What is aluminum foil for composite foil Aluminum foil for composite foil is an aluminum foil product used to make composite materials. Laminated foils usually consist of two or more layers of films of different materials, at least one of which is aluminum foil. These films can be bonded together using heat and pressure to form composites with multiple functions. Advantages of aluminum foil for composite foil ...

Aluminum foil for packaging bag introduction Aluminum foil bags are also called aluminum foil bags or aluminum foil packaging bags. Because aluminum foil has excellent barrier properties and protective capabilities, it is widely used to package a variety of products. These foil bags are commonly used to preserve the freshness, flavor and quality of food, pharmaceuticals, chemicals and other sensitive items. ...

What is 1050 H18 aluminum foil 1050 H18 aluminum foil is an aluminum foil material with high purity and good mechanical properties. Among them, 1050 represents the grade of aluminum alloy, and H18 represents the hardness level. 1050 aluminum alloy is an aluminum alloy with a purity of up to 99.5%, which has good corrosion resistance, thermal conductivity and machinability. H18 represents the aluminum foil aft ...

What is 5052 alloy aluminum foil? 5052 aluminum foil is a common aluminum alloy material, which is composed of aluminum, magnesium and other elements, and has the characteristics of medium strength, good corrosion resistance and weldability. It is a common aluminum alloy material for industrial use, usually used in the production of fuel tanks, fuel pipelines, aircraft parts, auto parts, building panels, etc. 5 ...

Single zero aluminum foil refers to aluminum foil with a thickness between 0.01mm ( 10 micron ) and 0.1mm ( 100 micron ). 0.01mm ( 10 micron ), 0.011mm ( 11 micron ), 0.012mm ( 12 micron ), 0.13mm ( 13 micron ), 0.14mm ( 14 micron ), 0.15mm ( 15 micron ), 0.16mm ( 16 micron ), 0.17mm ( 17 micron ), 0.18mm ( 18 micron ), 0.19mm ( 19 micron ) 0.02mm ( 20 micron ), 0.021mm ( 21 micron ), 0.022mm ( 22 micron ...

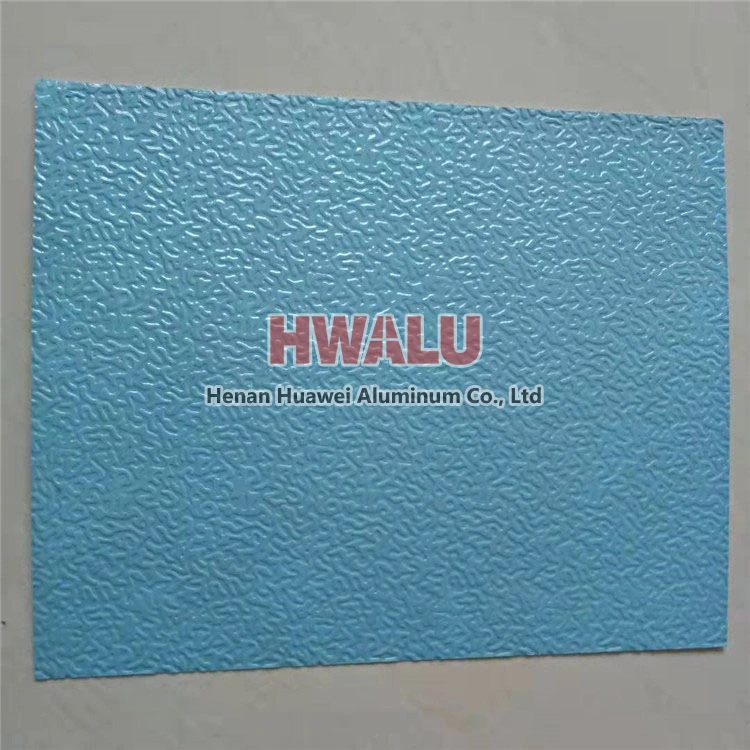

Specifications of sarin coated embossed aluminum foil Alloy model 1100 or 1200 3003 or 3004 5052, 5083, 5754 8011, 8079 Thickness 0.006mm-0.2mm Width 200mm-1600mm Flower type Common flower types include five flowers, tiger skin, pearl and so on. Coating sarin coating, color: gold, silver, red, green, blue, etc. Paper core inner diameter 76mm or 152mm Packing method w ...

1) Surface treatment (chemical etching, electrochemical etching, DC anodizing, corona treatment); 2) Conductive coating (surface coating carbon, graphene coating, carbon nanotube coating, composite coating); 3) 3D porous structure (foam structure, nanobelt structure, nano cone mechanism, fiber weaving mechanism); 4) Composite modification treatment. Among them, carbon coating on the surface is a commo ...

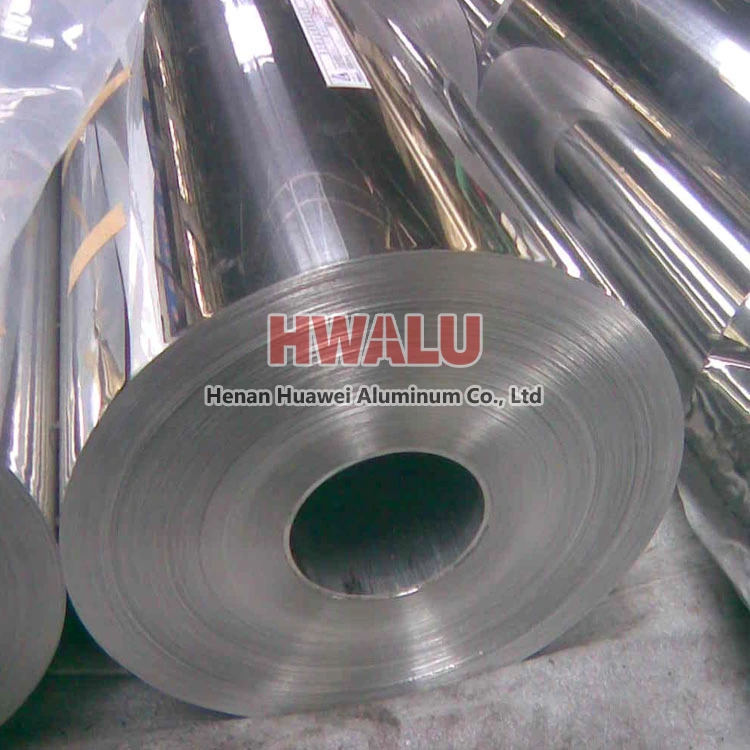

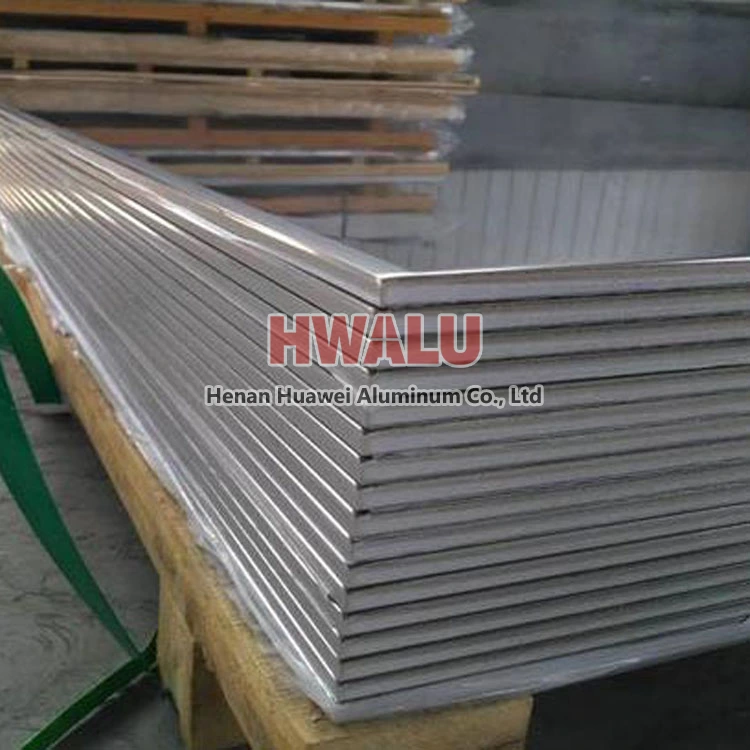

Aluminum foil is typically thinner than aluminum coil. Aluminum foil is typically available in various thicknesses, ranging from as thin as 0.005 mm (5 microns) up to 0.2 mm (200 microns). The most commonly used thicknesses for household aluminum foil are around 0.016 mm (16 microns) to 0.024 mm (24 microns). It is commonly used for packaging, cooking, and other household purposes. On the other hand, alumin ...

Since aluminum foil has shiny and matte sides, most of the resources found on search engines say this: When cooking food wrapped or covered with aluminum foil, the shiny side should face down, facing the food, and the dumb side Glossy side up. This is because the glossy surface is more reflective, so it reflects more radiant heat than matte, making the food easier to cook. Is it really? Let's analyze the heat ...

Fire or explosion in aluminum foil rolling must meet three conditions: combustible materials, such as rolling oil, cotton yarn, hose, etc.; combustible materials, that is, oxygen in the air; fire source and high temperature, such as friction, electric sparks, static electricity, open flames, etc. . Without one of these conditions, it will not burn and explode. The oil vapor and oxygen in the air generated duri ...

The most commonly used aluminum foil alloy in food packaging applications is 8011. Aluminum alloy 8011 is a typical alloy of aluminum foil and has become the industry standard for food packaging due to its excellent properties. Here are some reasons why alloy 8011 is ideal for food packaging: Good Barrier Performance: The aluminum foil made of 8011 alloy can effectively block moisture, oxygen and light, helpin ...

The rolling oil and other oil stains remaining on the surface of the foil, which are formed on the foil surface to varying degrees after annealing, are called oil spots. The main reasons for oil spots: high degree of oil in aluminum foil rolling, or inappropriate distillation range of rolling oil; mechanical oil infiltration in aluminum foil rolling oil; improper annealing process; excessive oil on the surface ...