What is aluminum foil for hookah Aluminum foil for hookah is a type of aluminum foil that is specifically designed and marketed for use in hookahs or water pipes. It is commonly used to cover the bowl of the hookah and hold the tobacco or shisha that is smoked through the pipe. Hookah foil is typically thinner than other types of aluminum foil, making it more pliable and easier to fit over the hookah bowl. It ...

Aluminum foil for capacitor parameters Alloy Temper Thickness Width Core inner diameter Maximum outer diameter of aluminum coil Thickness tolerance Wettability Brightness L Aluminum foil for capacitors 1235 0 0.005-0.016mm 100-500mm 76 500 ≦5 Class A (Brush water test) ≦60 aluminum foil capacitor The aluminum foil used in electrolytic capacitors is a corrosive material that wor ...

Specifications of sarin coated embossed aluminum foil Alloy model 1100 or 1200 3003 or 3004 5052, 5083, 5754 8011, 8079 Thickness 0.006mm-0.2mm Width 200mm-1600mm Flower type Common flower types include five flowers, tiger skin, pearl and so on. Coating sarin coating, color: gold, silver, red, green, blue, etc. Paper core inner diameter 76mm or 152mm Packing method w ...

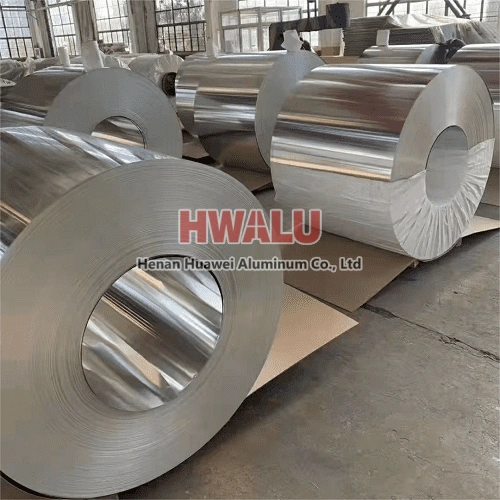

What is industrial aluminum foil roll Industrial aluminum foil rolls are jumbo aluminum foil, commonly used in various industrial applications. Industrial aluminum foil is a thin, flexible sheet made of aluminum metal, produced by rolling aluminum sheets cast from molten aluminum through a series of rolling mills to reduce thickness and create uniform specifications. Industrial aluminum foil rolls are different ...

Aluminum foil for disposable tableware Today, with the rapid economic development and the continuous improvement of the quality of life, aluminum foil for disposable tableware is used more and more frequently in daily life. Reasons for aluminum foil for disposable tableware Aluminum foil for disposable tableware can be waterproof, maintain freshness, prevent bacteria and stains, and maintain flavor and freshne ...

Aluminum foil is often used in our daily life, especially when we use microwave oven to heat food quickly. Can aluminum foil be used in microwave oven? Is it safe to do this? Please pay attention to the difference of microwave oven function, because different function mode, its heating principle is completely different, and the utensils used are also different. Now the market in addition to the microwave oven ...

Aluminum foil packaging development history: Aluminum foil packaging began in the early 20th century, when aluminum foil as the most expensive packaging material, only used for high-grade packaging. In 1911, the Swiss confectionery company began wrapping chocolate in aluminum foil, gradually replacing tinfoil in popularity. In 1913, based on the success of aluminum smelting, the United States began to produce ...

Pre-coated aluminum foil used for punching various containers, commonly used alloy 8011, 3003, 3004, 1145, etc., thickness is 0.02-0.08mm. Oiling thickness is 150-400mg/m². The use of aluminum foil as a semi-rigid container to hold food has been widely adopted at home and abroad. With the continuous development of the national economy and the continuous improvement of people’s living standards, people’s health ...

Product name: plain aluminum foil SIZE (MM) ALLOY / TEMPER 0.1MM*1220MM*200M 8011 O

Beer caps can be packed in aluminum foil. Aluminum foil is a commonly used packaging material due to its excellent barrier properties, protecting contents from light, moisture and external contaminants. It helps maintain the freshness and quality of the product. Beer caps are small, lightweight and can be easily wrapped or packaged in aluminum foil. There are several reasons for doing this, including: 1 ...

Coiling defects mainly refer to loose, layer channeling, tower shape, warping and so on. Aluminum foil roll during the winding process. Because the tension of aluminum foil is limited, enough tension is the condition to form a certain tension gradient. Therefore, the winding quality ultimately depends on good shape, reasonable process parameters and suitable precision sleeve. It is ideal to obtain tight coils ...