What is aluminum foil for pill packaging Aluminum foil for pill packaging is a kind of aluminum foil used for pharmaceutical packaging. This aluminum foil is usually very thin and has properties such as waterproof, anti-oxidation and anti-light, which can effectively protect the pills from external influences such as moisture, oxygen and light. Aluminum foil for pill packaging usually has the following advantage ...

What is 13 micron aluminum foil? "Aluminum Foil 13 Micron" is a thin and light aluminum foil that falls within the thickness range of household aluminum foil and is commonly used for various packaging and insulation purposes. It is a very common thickness specification. 13 micron aluminum foil equivalent name 13μm aluminum foil 0.013mm aluminum foil Household packaging aluminum foil 13 micron aluminum foil ...

Aluminum foil for heat seal product Aluminum foil heat seal coating is a common packaging material. Aluminum foil for heat seal has good moisture-proof, anti-fluorination, anti-ultraviolet and other properties, and can protect food, medicine and other items that are susceptible to external influences. Characteristics of heat sealing aluminum foil During the production process of aluminum foil heat seal coa ...

what is Aluminum Foil For Microwave Oven It is commonly used to cover or wrap food items during microwave cooking, reheating, or defrosting to prevent moisture loss, splattering, and to promote even heating. However, it is important to note that not all aluminum foil is safe for use in microwave ovens. Regular aluminum foil can cause sparks and potentially damage the microwave oven, or even start a fire. Ther ...

Welcome to Huawei Aluminum, your trusted partner in the world of aluminum foil. We are a leading aluminum foil 8011 12-micron factory and wholesaler, committed to delivering high-quality products that cater to a wide range of industries. In this comprehensive guide, we will explore everything you need to know about our Aluminum Foil 8011, its specifications, and applications. 1. Introduction to Aluminum Foil ...

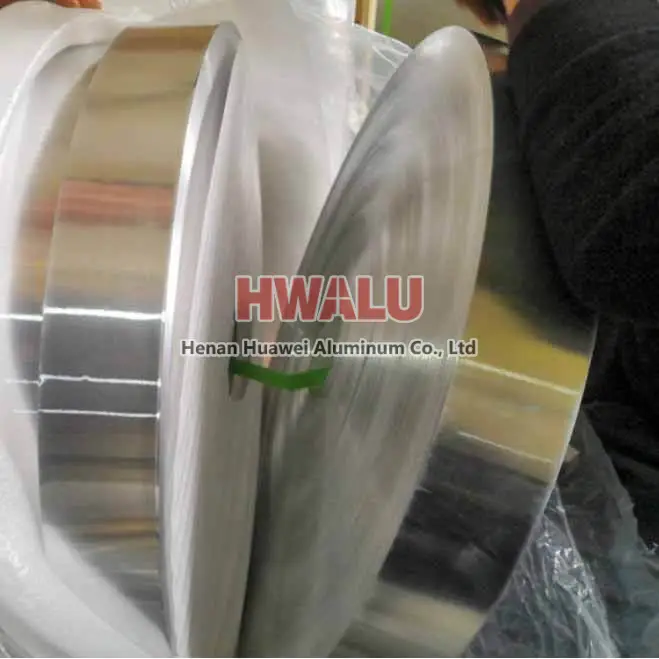

What is aluminum foil for cable? The outer surface of the cable needs to be wrapped with a layer of aluminum foil for protection and shielding. This kind of aluminum foil is usually made of 1145 grade industrial pure aluminum. After continuous casting and rolling, cold rolling, slitting and complete annealing, it is divided into small coils according to the length required by the user and supplied to the cable f ...

1. Insulation and fragrance preservation Aluminum foil lunch boxes are usually used as paper-wrapped beverage packaging. The thickness of the aluminum foil in the packaging bag is only 6.5 microns. This thin aluminum layer can be waterproof, preserve umami, anti-bacterial and anti-fouling. The characteristics of preservation of fragrance and freshness make the aluminum foil lunch box possess the properties of fo ...

The selection principle of pass processing rate is as follows: (1) Under the premise that the equipment capacity allows the rolling oil to have good lubrication and cooling performance, and can obtain good surface quality and shape quality, the plasticity of the rolled metal should be fully utilized, and the large pass processing rate should be used as much as possible to improve the rolling mill Production ef ...

In the production process of aluminum foil, there are multiple processes such as rolling, finishing, annealing, packaging, etc. The interlocking production process, any problem in any link may cause aluminum foil quality problems. The quality defects of the purchased aluminum foil products will not only affect the appearance, but also directly affect the quality of the products produced, and even more directly ca ...

Aluminum foil jumbo roll: Ideal for cooking or baking large dishes such as roasts, turkeys or baked cakes as it covers the entire dish with ease. Ideal for wrapping leftovers or storing food in the freezer, as you can cut the desired length of foil as needed. Aluminum foil jumbo rolls can last for a long time, which can save costs in long-term use. Small rolls of aluminum foil: More portable an ...

The rolling oil and other oil stains remaining on the surface of the foil, which are formed on the foil surface to varying degrees after annealing, are called oil spots. The main reasons for oil spots: high degree of oil in aluminum foil rolling, or inappropriate distillation range of rolling oil; mechanical oil infiltration in aluminum foil rolling oil; improper annealing process; excessive oil on the surface ...

Aluminum foil plays a vital role in the construction of lithium-ion batteries. There are many models in the 1000-8000 series alloys that can be used in battery production. Pure aluminum foil: Pure aluminum foil commonly used in lithium batteries includes various alloy grades such as 1060, 1050, 1145, and 1235. These foils are usually in different states such as O, H14, H18, H24, H22. Especially alloy 1145. ...