What is aluminum foil for pill packaging Aluminum foil for pill packaging is a kind of aluminum foil used for pharmaceutical packaging. This aluminum foil is usually very thin and has properties such as waterproof, anti-oxidation and anti-light, which can effectively protect the pills from external influences such as moisture, oxygen and light. Aluminum foil for pill packaging usually has the following advantage ...

PTP aluminum Blister foil parameter Alloy 1235, 8011, 8021 etc Temper O( HO ), H18, etc Width 300mm, 600mm, etc Thickness OP: 0.5 - 1.5 g/m2 Aluminum foil: 20 micron ( 0.02mm ), 25 micron ( 0.025mm ), 30 micron ( 0.3mm ) etc HSL ( VC ):3 - 4.5 gsm Primer: 1gsm Surface treatment Laminated, printing, Single bright side, etc What is ptp aluminum blister foil ...

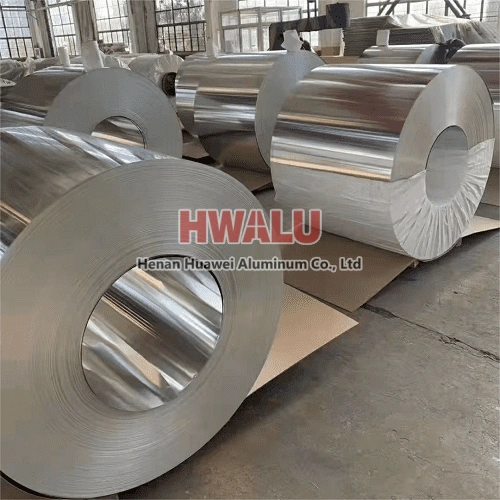

What is industrial aluminum foil roll Industrial aluminum foil rolls are jumbo aluminum foil, commonly used in various industrial applications. Industrial aluminum foil is a thin, flexible sheet made of aluminum metal, produced by rolling aluminum sheets cast from molten aluminum through a series of rolling mills to reduce thickness and create uniform specifications. Industrial aluminum foil rolls are different ...

What is a lidding foil? Lidding foil, also known as lid foil or lid, is a thin sheet of aluminum or composite material used to seal containers such as cups, jars, and trays to protect the contents inside. Lidding foils come in a variety of shapes, sizes, and designs to suit different types of containers and packaging applications. They can be printed with branding, logos, and product information to enhance a ...

what is Aluminum foil for capsule packaging? Compared with traditional capsule packaging materials, aluminum foil for capsule packaging has better moisture-proof, anti-oxidation and fresh-keeping properties, which can better protect the quality and safety of medicines. Reasons for choosing aluminum foil for capsule packaging Good moisture-proof performance: prevent the medicines in the capsules from moistu ...

Aluminum foil is a thin sheet of aluminum metal that has the following properties: Lightweight: Aluminum foil is very lightweight because aluminium metal itself is a lightweight material. This makes aluminum foil an ideal material during packaging and shipping. Good sealing: The surface of aluminum foil is very smooth, which can effectively prevent the penetration of oxygen, water vapor and other gases, s ...

Aluminum foil is typically thinner than aluminum coil. Aluminum foil is typically available in various thicknesses, ranging from as thin as 0.005 mm (5 microns) up to 0.2 mm (200 microns). The most commonly used thicknesses for household aluminum foil are around 0.016 mm (16 microns) to 0.024 mm (24 microns). It is commonly used for packaging, cooking, and other household purposes. On the other hand, alumin ...

Cast-rolled aluminum foil production process Aluminum liquid, aluminum ingot -> Smelt -> Continuous roll casting -> Winding -> Cast roll finished product Plain foil production process Plain foil -> Cast-rolled coil -> Cold rolled -> Foil rolling -> Slitting -> Annealing -> Plain foil finished product The manufacture of aluminum foil is similar to making pasta at home. A large b ...

Aluminum foil is a good packaging material, which can be used as food packaging, pharmaceutical packaging, and can also be used as a yogurt lid on yogurt. And aluminum foil is a common material choice for yogurt lids. The production process of aluminum foil for yogurt lid: Aluminum foil: Choose high-quality aluminum foil suitable for food packaging. It should be clean, free of any contaminants, and the cover sh ...

Aluminum foil packaging development history: Aluminum foil packaging began in the early 20th century, when aluminum foil as the most expensive packaging material, only used for high-grade packaging. In 1911, the Swiss confectionery company began wrapping chocolate in aluminum foil, gradually replacing tinfoil in popularity. In 1913, based on the success of aluminum smelting, the United States began to produce ...

In the production process of aluminum foil, there are multiple processes such as rolling, finishing, annealing, packaging, etc. The interlocking production process, any problem in any link may cause aluminum foil quality problems. The quality defects of the purchased aluminum foil products will not only affect the appearance, but also directly affect the quality of the products produced, and even more directly ca ...