What is cable aluminum foil? Cable aluminum foil is a special type of aluminum foil used for cable structures. It is processed from aluminum alloy raw materials through cold rolling, hot rolling and other processes. Aluminum foil used in cables has excellent electrical conductivity and good corrosion resistance, especially in the telecommunications and electrical industries, playing an important role. 8011 ...

What is Aluminum Foil for Pans Aluminum foil for pans is usually thicker and stronger than typical kitchen foil to withstand high heat and stress. Aluminum foil for pans can be used to cover the bottom of pans to keep food from sticking to them, and to make liners for steamers and bakeware to prevent food from sticking to the bottom or to the pan. The use of aluminum foil for pans is similar to that of ordina ...

leading manufacturer and wholesaler of high-quality 1200 Aluminum Foil At Huawei Aluminum, we take pride in being a leading manufacturer and wholesaler of high-quality 1200 Aluminum Foil. With a rich history of delivering top-notch products to our global clientele, we are committed to excellence in both quality and service. Explore our comprehensive range of 1200 Aluminum Foil, where precision meets purity. ...

What is aluminum foil for pallets Aluminum tray foil is an aluminum foil material used to wrap and cover food trays. This aluminum foil usually has a larger area and a thinner thickness to fit the size and shape of the tray and can resist high temperature and humidity to protect food from contamination and damage. Aluminum foil for trays is widely used in the food service industry, especially in hotels, resta ...

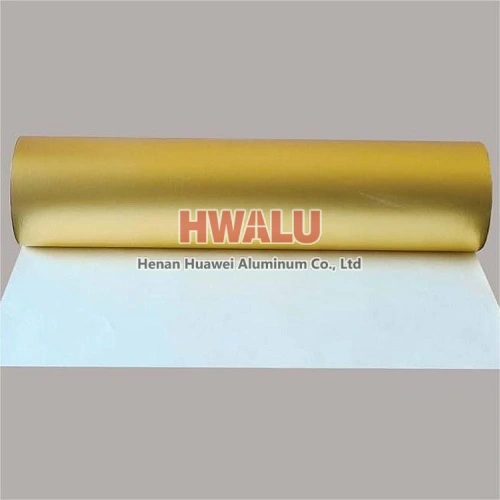

Gold aluminum foil roll The color of aluminum foil itself is silver-white, and gold aluminum foil refers to aluminum flakes that have a golden surface after being coated or treated. Aluminum foil gold can give a very good visual appearance. This type of foil is often used for decorative purposes, arts and crafts and various packaging applications that require a metallic gold appearance. Heavy duty gold alum ...

8006 aluminum foil is mainly used for food packaging, such as milk boxes, juice boxes, etc. 8006 aluminum foil has good corrosion resistance and mechanical properties, which can meet various packaging needs. 8011 aluminum foil is a common aluminum alloy material, mainly used in food packaging and pharmaceutical packaging. 8011 aluminum foil has good waterproof, moisture-proof and oxidation-proof properties, an ...

Aluminum foil is a good packaging material, which can be used as food packaging, pharmaceutical packaging, and can also be used as a yogurt lid on yogurt. And aluminum foil is a common material choice for yogurt lids. The production process of aluminum foil for yogurt lid: Aluminum foil: Choose high-quality aluminum foil suitable for food packaging. It should be clean, free of any contaminants, and the cover sh ...

Aluminum foil is a good heat insulator because it is a poor conductor of heat. Heat can only be transferred through a material by conduction, convection, or radiation. In the case of aluminum foil, heat transfer occurs primarily through radiation, which is the emission of electromagnetic waves from the surface of an object. Aluminum foil is a shiny, reflective material that reflects radiant heat back towards i ...

1. The raw materials are non-toxic and the quality is safe Aluminum foil is made of primary aluminum alloy after rolling through multiple processes, and it has no harmful substances such as heavy metals. In the aluminum foil production process, a high-temperature annealing and disinfection process is used. Therefore, the aluminum foil can be safely in contact with food and will not contain or help the growth o ...

Why Can Aluminum Foil Conduct Electricity? Do you know how aluminum foil conducts electricity? Aluminum foil is a good conductor of electricity because it is made of aluminum, which has a high electrical conductivity. Electrical conductivity is the measure of how well a material conducts electricity. Materials with high electrical conductivity allow electricity to flow through them easily because they have many ...

1) Surface treatment (chemical etching, electrochemical etching, DC anodizing, corona treatment); 2) Conductive coating (surface coating carbon, graphene coating, carbon nanotube coating, composite coating); 3) 3D porous structure (foam structure, nanobelt structure, nano cone mechanism, fiber weaving mechanism); 4) Composite modification treatment. Among them, carbon coating on the surface is a commo ...