What is aluminum foil for insulation? Aluminum foil for insulation is a type of aluminum foil that is used in various forms of insulation to help reduce heat loss or gain. It is a highly effective material for thermal insulation due to its low thermal emissivity and high reflectivity. Aluminum foil for insulation is commonly used in the construction industry for insulating walls, roofs, and floors of building ...

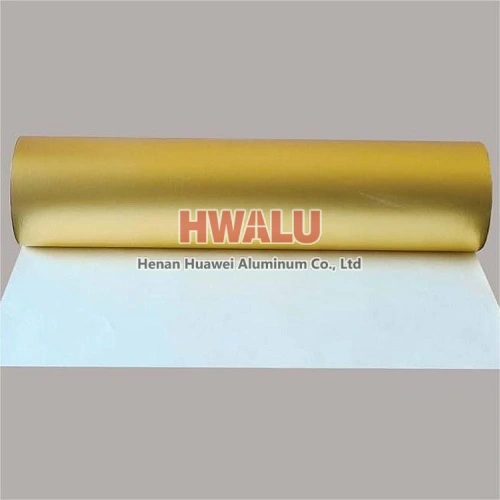

Gold aluminum foil roll The color of aluminum foil itself is silver-white, and gold aluminum foil refers to aluminum flakes that have a golden surface after being coated or treated. Aluminum foil gold can give a very good visual appearance. This type of foil is often used for decorative purposes, arts and crafts and various packaging applications that require a metallic gold appearance. Heavy duty gold alum ...

what is 8021 alloy aluminum foil? 8021 alloy aluminum foil has excellent moisture resistance, shading, and extremely high barrier ability: elongation, puncture resistance, and strong sealing performance. The aluminum foil after compounding, printing, and gluing is widely used as a packaging material. Mainly used for food packaging, blister drug packaging, soft battery packs, etc. The Advantages Of 8021 a ...

Double zero aluminum foil refers to aluminum foil with a thickness between 0.001mm ( 1 micron ) and 0.01mm ( 10 micron ). Such as 0.001mm ( 1 micron ), 0.002mm ( 2 micron ), 0.003mm ( 3 micron ), 0.004mm ( 4 micron ), 0.005mm ( 5 micron ), 0.006mm ( 6 micron ), 0.007mm ( 7 micron ), 0.008mm ( 8 micron ), 0.009mm ( 9 micron ) 0.005 mic aluminium foil Advantages of 0.001-0.01 micron aluminum foil An ...

What is aluminum foil for insulation? Aluminum foil for insulation is a type of aluminum foil that is used in various forms of insulation to help reduce heat loss or gain. It is a highly effective material for thermal insulation due to its low thermal emissivity and high reflectivity. Aluminum foil for insulation is commonly used in the construction industry for insulating walls, roofs, and floors of building ...

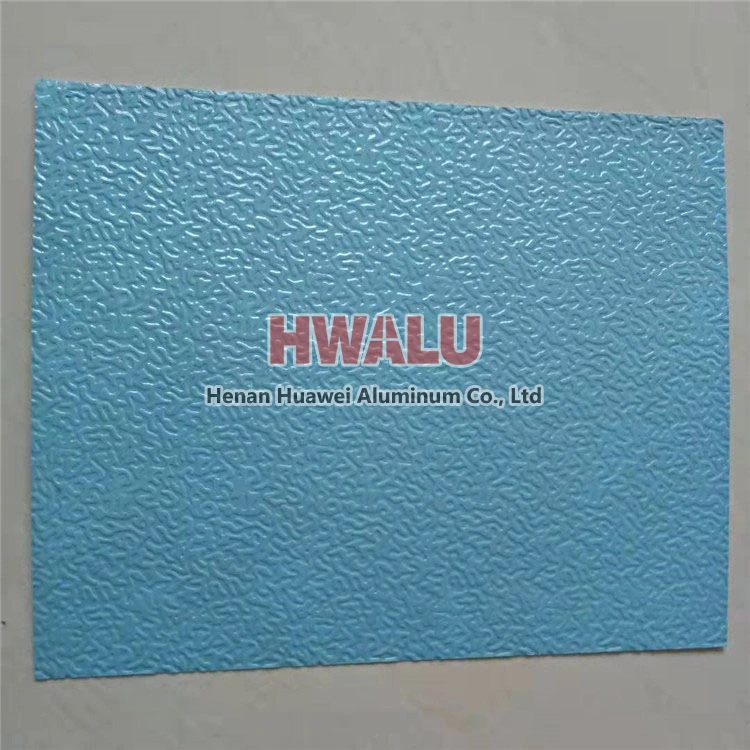

Specifications of sarin coated embossed aluminum foil Alloy model 1100 or 1200 3003 or 3004 5052, 5083, 5754 8011, 8079 Thickness 0.006mm-0.2mm Width 200mm-1600mm Flower type Common flower types include five flowers, tiger skin, pearl and so on. Coating sarin coating, color: gold, silver, red, green, blue, etc. Paper core inner diameter 76mm or 152mm Packing method w ...

Aluminum foil is a versatile material with a wide range of uses across various industries and households. Here are some common uses of aluminum foil: Packaging: Aluminum foil is widely used in packaging applications. It is used to wrap food items, such as sandwiches, snacks, and leftovers, to keep them fresh and protect them from moisture, light, and odors. It is also used for packaging pharmaceutical products ...

1. Insulation and fragrance preservation Aluminum foil lunch boxes are usually used as paper-wrapped beverage packaging. The thickness of the aluminum foil in the packaging bag is only 6.5 microns. This thin aluminum layer can be waterproof, preserve umami, anti-bacterial and anti-fouling. The characteristics of preservation of fragrance and freshness make the aluminum foil lunch box possess the properties of fo ...

Fire or explosion in aluminum foil rolling must meet three conditions: combustible materials, such as rolling oil, cotton yarn, hose, etc.; combustible materials, that is, oxygen in the air; fire source and high temperature, such as friction, electric sparks, static electricity, open flames, etc. . Without one of these conditions, it will not burn and explode. The oil vapor and oxygen in the air generated duri ...

Aluminum foil rolling produces plastic deformation under the conditions of roll-free rolling. At this time, the rolling mill frame is elastically deformed and the rolls are elastically flattened. When the thickness of the rolled piece reaches a smaller and more limited thickness h. When the rolling pressure has no effect, it is very difficult to make the rolled piece thinner. Usually two pieces of aluminum foi ...

Is aluminum foil a good insulator? It is certain that aluminum foil itself is not a good insulator, because aluminum foil can conduct electricity. Aluminum foil has relatively poor insulation properties. Although aluminum foil has certain insulating properties in some cases, its insulating properties are not as good as other insulating materials. Because under normal circumstances, the surface of aluminum foi ...

The biggest feature of aluminum foil is its light weight and wide range of uses, suitable for aviation, construction, decoration, industry and other industries. Aluminum is very cost-effective, and its electrical conductivity is second only to that of copper, but the price is much cheaper than that of copper, so many people now choose aluminum as the main material for wires. 1060, 3003, 5052 are several common ...