Introduction of 8079 alloy aluminum foil What is aluminum foil grade 8079? 8079 alloy aluminum foil usually used to produce kinds of aluminum alloy foil, which offers the best properties for many applications with H14, H18 and other tempers and thicknesses between 10 and 200 microns. The tensile strength and elongation of alloy 8079 are higher than other alloys, so it is not flexible and moisture resistant. ...

Basic parameters of aluminum foil for food packaging Thickness: 0.006-0.2mm Width: 20-1600mm Material state: O, H14, H16, H18, etc. Fields of application: packaged cooked food, marinated products, bean products, candy, chocolate, etc. What properties does aluminum foil use for food packaging bags? Foil has outstanding properties of impermeability (especially for oxygen and water vapor) and shading, an ...

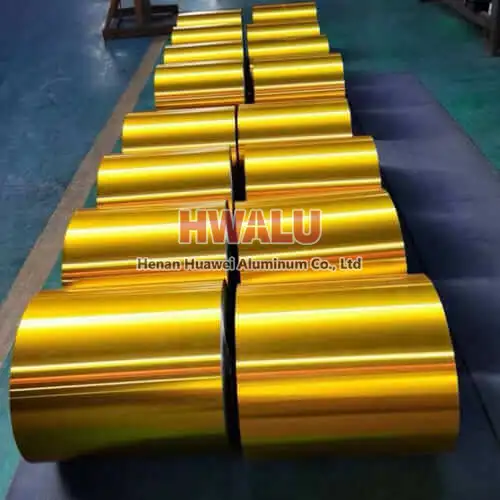

Black Gold Aluminum foil Black Gold Aluminum foil refers to aluminum foil with black or gold spray coating on the surface, and also has one side of gold and one side of very colored aluminum foil. Black aluminum foil is mostly used in aluminum foil tape, air duct materials, etc. Gold aluminum foil is widely used and is often used in chocolate packaging, pharmaceutical packaging, aluminum foil lunch box ...

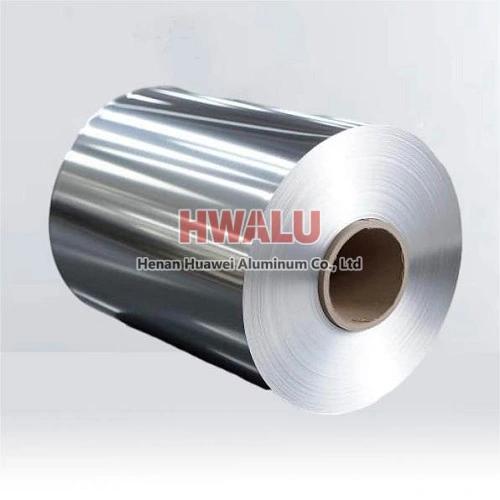

Soft Temper Jumbo Aluminum Foil Roll Introduction Welcome to Huawei Aluminum, your trusted partner in the world of aluminum foil solutions. As a leading factory and wholesaler, we take pride in offering premium Soft Temper Jumbo Aluminum Foil Rolls that cater to a diverse range of industries and applications. With a commitment to quality and excellence, Huawei Aluminum stands as a beacon of reliability in the al ...

Alloy type of aluminum foil for cosmetics 8011 aluminum foil 8021 alloy aluminum foil 8079 aluminum foil alloy Where is aluminum foil for cosmetics used in cosmetics? 1-Packaging: Some products in cosmetics, such as facial masks, eye masks, lip masks, patches, etc., usually use aluminum foil packaging, because aluminum foil has good moisture-proof, anti-oxidation, heat insulation, fresh-keeping and ...

Aluminum foil lunch box is not a new thing, but it is really the last two or three years is particularly active. In particular, the hot sealing aluminum foil lunch box, because it is the first sealed food and then high-temperature cooking disinfection, in the consumer to open the taste before the maximum ensure food safety and health, full tightness, and high barrier can also be a good lock food flavor. Even i ...

Fire or explosion in aluminum foil rolling must meet three conditions: combustible materials, such as rolling oil, cotton yarn, hose, etc.; combustible materials, that is, oxygen in the air; fire source and high temperature, such as friction, electric sparks, static electricity, open flames, etc. . Without one of these conditions, it will not burn and explode. The oil vapor and oxygen in the air generated duri ...

I can't believe that there are 20 uses for aluminum foil! ! ! Aluminum foil is a widely used material. Aluminum foil has a wide range of uses in daily life and industrial applications due to its light weight, good processing performance, high reflectivity, high temperature resistance, moisture resistance, corrosion resistance and other characteristics. Here are twenty uses of aluminum foil: 1. Alumin ...

In the production of double foil, the rolling of aluminum foil is divided into three processes: rough rolling, intermediate rolling, and finishing rolling. From a technological point of view, it can be roughly divided from the thickness of the rolling exit. The general method is that the exit thickness is greater than Or equal to 0.05mm is rough rolling, the exit thickness is between 0.013 and 0.05 is intermediat ...

Aluminum foil and aluminum coil are both versatile aluminum alloy materials used in different applications across various industries. Aluminum coil alloy and aluminum foil alloy have similar properties in many aspects, but also have many different characteristics. Huawei will make a detailed comparison between the two in terms of properties, uses, etc.: What are aluminum coils and aluminum foil? Aluminum Foil: ...

Extra-wide aluminum foil serves several purposes and finds applications in various industries. Here are some common uses for extra-wide aluminum foil: Extra wide aluminum foil for Industrial Insulation: Extra-wide aluminum foil is often used for insulation in industrial settings. It is effective in reflecting radiant heat, making it suitable for insulating large areas in construction, manufacturing, and oth ...