Welcome to Huawei Aluminum, your trusted partner in the world of aluminum foil. We are a leading aluminum foil 8011 12-micron factory and wholesaler, committed to delivering high-quality products that cater to a wide range of industries. In this comprehensive guide, we will explore everything you need to know about our Aluminum Foil 8011, its specifications, and applications. 1. Introduction to Aluminum Foil ...

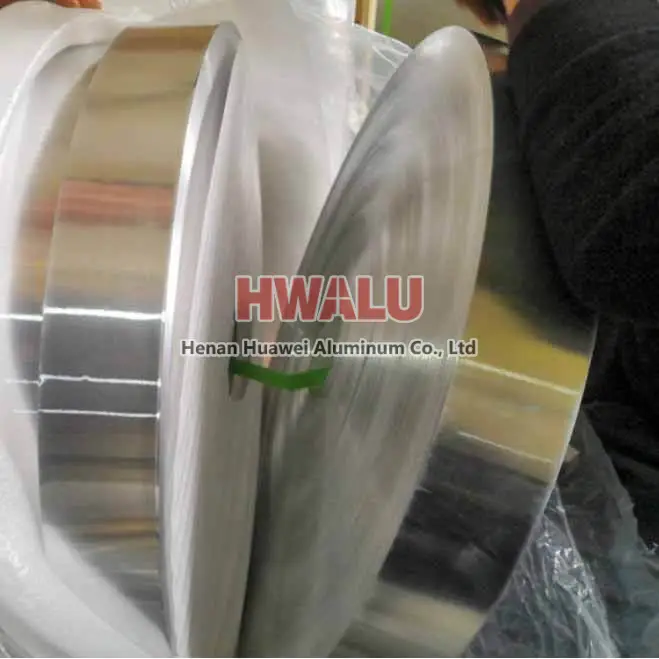

What is aluminum foil for transformers Aluminum foil for transformers refers to the aluminum foil used to make transformers. A transformer is an electrical device used to transform alternating voltage or current, consisting of an iron core and a winding. A winding consists of an insulated coil and a conductor, usually copper wire or foil. Aluminum foil can also be used as a winding conductor. Aluminum foil fo ...

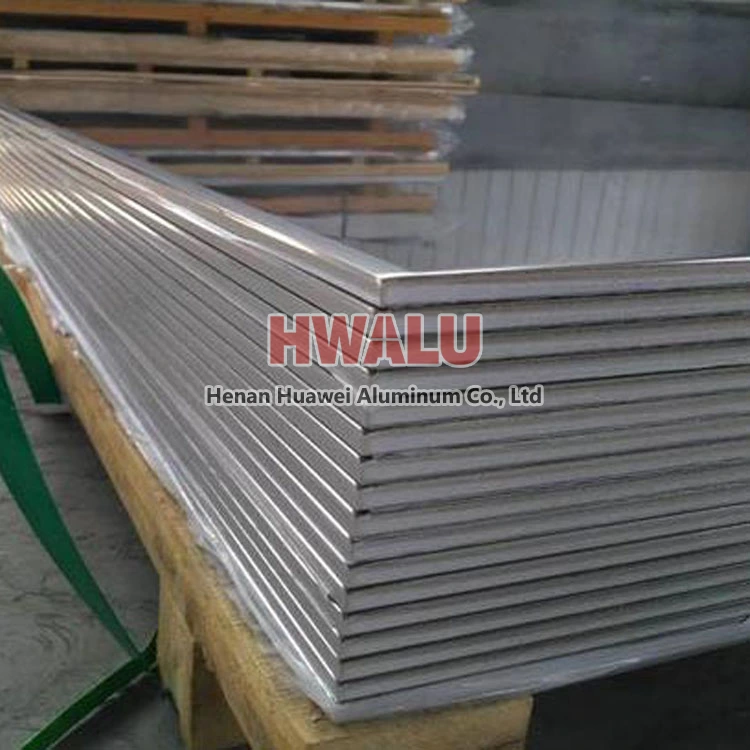

What is 5052 alloy aluminum foil? 5052 aluminum foil is a common aluminum alloy material, which is composed of aluminum, magnesium and other elements, and has the characteristics of medium strength, good corrosion resistance and weldability. It is a common aluminum alloy material for industrial use, usually used in the production of fuel tanks, fuel pipelines, aircraft parts, auto parts, building panels, etc. 5 ...

What is aluminum foil for cake cup? Aluminum foil can be used for many purposes in baking, such as making cupcake cups or liners. Aluminum foil cake cups are cup-shaped containers used for baking cakes, cupcakes, or cupcakes, usually made of aluminum foil. Cake cup aluminum foil is used to wrap the bottom and sides of the cake cup to maintain the shape of the cake when baking, prevent sticking, and make the ca ...

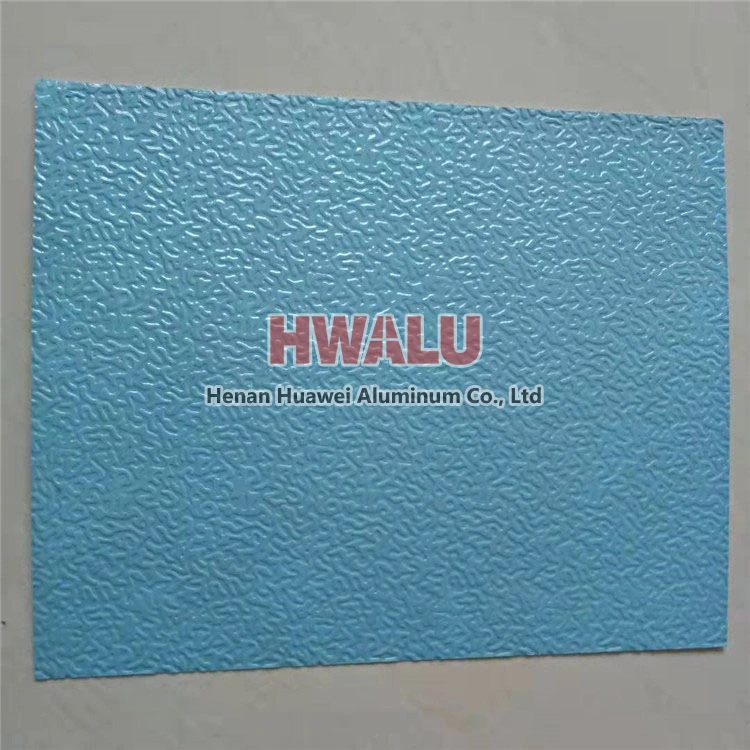

Specifications of sarin coated embossed aluminum foil Alloy model 1100 or 1200 3003 or 3004 5052, 5083, 5754 8011, 8079 Thickness 0.006mm-0.2mm Width 200mm-1600mm Flower type Common flower types include five flowers, tiger skin, pearl and so on. Coating sarin coating, color: gold, silver, red, green, blue, etc. Paper core inner diameter 76mm or 152mm Packing method w ...

Oven bottom: Do not spread aluminum foil on the bottom of the oven. This could cause the oven to overheat and cause a fire. Use with acidic foods: Aluminum foil should not come in contact with acidic foods such as lemons, tomatoes, or other acidic foods. These foods can dissolve the aluminum foil, increasing the aluminum content of the food. Bake Clean Oven Racks: Aluminum foil should not be used to cov ...

1. Uncoated aluminum foil Uncoated aluminum foil refers to aluminum foil that has been rolled and annealed without any form of surface treatment. In my country 10 years ago, the aluminum foil used for air-conditioning heat exchangers in foreign countries about 15 years ago was all uncoated aluminum foil. Even at present, about 50% of the heat exchange fins used in foreign developed countries are still uncoated ...

Aluminum foil has the following advantages in food packaging: Barrier property. Aluminum foil has excellent resistance to water, air (oxygen), light, and microorganisms, which are important factors in food spoilage. Therefore, aluminum foil has a good protective effect on food. Easy processing. Aluminum has a low melting point, good heat sealing, and easy molding. Can be processed into any shape according to ...

Is the aluminum foil in the oven toxic? Please pay attention to the difference between the oven and the microwave. They have different heating principles and different utensils. The oven is usually heated by electric heating wires or electric heating pipes. Microwave ovens rely on microwaves to heat. The oven heating tube is a heating element that can heat the air and food in the oven after the oven is pow ...

Anodized Aluminum Foil Overview Anodized aluminum foil is aluminum foil that has been anodized. Anodizing is an electrochemical process in which aluminum foil is immersed in an electrolyte solution and an electric current is applied. This causes oxygen ions to bond with the aluminum surface, forming a layer of aluminum oxide. It can increase the thickness of the natural oxide layer on the aluminum surface. This ...

https://www.youtube.com/watch?v=ZR_JvbVongU The shocking statistics released by the National Center for Cardiovascular Diseases suggest that China has the highest occurrence of sudden cardiac deaths (SCD) in the world, accounting for over 544,000 deaths annually. That is to say, SCDs occur at a rate of 1,500 people/day or one person/minute in China. According to David Jin, general manager of Henan Huawei Alumi ...