Custom printing aluminum foil jumbo roll The printing process and precautions of aluminum foil for medicine packs The process flow of packaging aluminum foil is: aluminum foil unwinding -> gravure printing -> drying -> protective layer coating -> drying -> adhesive layer coating -> drying -> aluminum foil winding. In order to achieve the above-mentioned performance requirements in the PTP ...

What is aluminum foil for wine Aluminum foil for wine has excellent properties such as moisture-proof, anti-oxidation, heat insulation, and odor insulation, which can protect the quality and taste of wine products. In wine packaging, common aluminum foil materials include aluminized polyester film, aluminized polyamide film, etc. Aluminum foil for wine usually has a certain thickness and strength, which ca ...

Introduction of 8079 alloy aluminum foil What is aluminum foil grade 8079? 8079 alloy aluminum foil usually used to produce kinds of aluminum alloy foil, which offers the best properties for many applications with H14, H18 and other tempers and thicknesses between 10 and 200 microns. The tensile strength and elongation of alloy 8079 are higher than other alloys, so it is not flexible and moisture resistant. ...

Why does hair use aluminum foil? The use of aluminum foil for hair is often done during hair coloring, especially when a specific pattern or effect is desired. Aluminum foil can help isolate and hold the hair dye in place, ensuring it only goes where it's needed, creating a more precise and detailed finish. When coloring hair, hairdressers usually divide the hair to be colored into sections and wrap each sect ...

What is bright aluminum foil? Bright aluminum foil is a kind of aluminum foil material with a smooth surface and good reflective properties. It is usually made of high-purity aluminum metal material through multiple precision machining processes. In the manufacturing process, aluminum metal is rolled into very thin sheets, which are then specially treated The rollers are repeatedly rolled until the surfac ...

What Is Food Packaging Aluminium Foil Roll 8011 As we all know, aluminum foil is widely used in our daily life, especially in the field of food packaging. Aluminum foil roll 8011 is a common food packaging material. 8011 aluminum alloy is a high-quality aluminum alloy with good ductility, strength and corrosion resistance. This type of aluminum foil is commonly used for food packaging. 8011 aluminum fo ...

It is a characteristic of aluminum box rolling that the thickness deviation is difficult to control. The thickness difference of 3% is not difficult to control in the production of plate and strip, but it is more difficult to control in the production of aluminum foil. As the thickness of the aluminum box becomes thinner, its micro-conditions can affect it, such as temperature, oil film, and oil and gas concen ...

As the name suggests, an air fryer is a machine that uses air to "fry" food. It by using the principle of high-speed air circulation, mainly through the heating tube to heat the air, and then the fan will air into high-speed circulation heat flow, when the food is heating, hot air convection can make food fast dehydration, the oil of baking food itself, in the end, become golden crispy food surface, appear simila ...

Aluminum foil paper is almost a must-have item for every family, but do you know that besides cooking, does aluminum foil paper have any other functions? Now we have sorted out 9 usages of aluminum foil paper, which can clean, prevent aphids, save electricity, and prevent static electricity. From today, don’t throw away after cooking with aluminum foil paper. Using the characteristics of aluminum foil paper will ...

For the capsule shell, because it is made of aluminum, aluminum is an infinitely recyclable material. Capsule coffee generally uses an aluminum casing. Aluminum is the most protective material at present. It can not only lock the aroma of coffee, but also is light in weight and high in strength. At the same time, aluminum protects the coffee from foreign substances such as oxygen, moisture and light. For cof ...

Household foil is widely used in cooking, freezing, preservation, baking and other industries. The disposable aluminum foil paper has the advantages of convenient use, safety, sanitation, no odor and no leakage. In the refrigerator or freezer, aluminum foil can be directly wrapped on the food, which can keep the food from deformation, avoid the water loss of fish, vegetables, fruits and dishes, and prevent the le ...

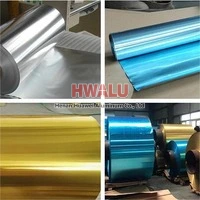

Anodized Aluminum Foil Overview Anodized aluminum foil is aluminum foil that has been anodized. Anodizing is an electrochemical process in which aluminum foil is immersed in an electrolyte solution and an electric current is applied. This causes oxygen ions to bond with the aluminum surface, forming a layer of aluminum oxide. It can increase the thickness of the natural oxide layer on the aluminum surface. This ...