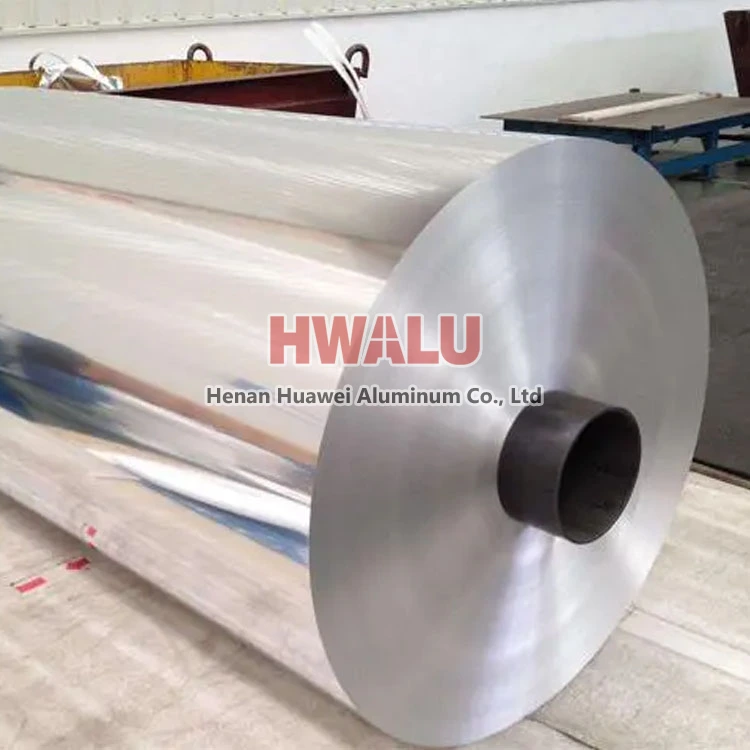

Single zero aluminum foil refers to aluminum foil with a thickness between 0.01mm ( 10 micron ) and 0.1mm ( 100 micron ). 0.01mm ( 10 micron ), 0.011mm ( 11 micron ), 0.012mm ( 12 micron ), 0.13mm ( 13 micron ), 0.14mm ( 14 micron ), 0.15mm ( 15 micron ), 0.16mm ( 16 micron ), 0.17mm ( 17 micron ), 0.18mm ( 18 micron ), 0.19mm ( 19 micron ) 0.02mm ( 20 micron ), 0.021mm ( 21 micron ), 0.022mm ( 22 micron ...

How to define light gauge aluminum foil? Light gauge aluminum foil usually refers to aluminum foil with a thickness of less than 0.01mm, that is, aluminum foil with a thickness of 0.0045mm~0.0075mm. 1mic=0.001mm Example: 6 mic aluminum foil, 5.3 mic aluminum foil Aluminum foil with thickness ≤40ltm can also be called "light gauge foil", and aluminum foil with thickness >40btm can be called "heavy gau ...

What is 5052 alloy aluminum foil? 5052 aluminum foil is a common aluminum alloy material, which is composed of aluminum, magnesium and other elements, and has the characteristics of medium strength, good corrosion resistance and weldability. It is a common aluminum alloy material for industrial use, usually used in the production of fuel tanks, fuel pipelines, aircraft parts, auto parts, building panels, etc. 5 ...

What is Yogurt Lid Foil? Yogurt Lid Foil is made of food-grade aluminum foil material, which can ensure that no harmful substances are released and is harmless to the human body. Foil yogurt lid is usually in the process of making yogurt, aluminum foil is sealed on the cup lid by special sealing equipment. Because of the good moisture resistance and oxygen barrier properties of aluminum foil, it can effective ...

Introduction: Welcome to Huawei Aluminum, a trusted name in the aluminum industry. Our 14 Micron Aluminum Foil for Food Use is a top-quality product that serves various purposes in the food packaging and laminated materials sector. In this detailed guide, we will delve into the specifics of our 14 Micron Aluminum Foil, discussing its alloy models, specifications, applications, advantages, and more. Alloy Mo ...

What is extra wide aluminum foil "Extra-wide aluminum foil" refers to aluminum foil that is wider than commonly used standard widths. Aluminum foil is a thin sheet of metal used for a variety of purposes, including packaging food, covering cooking dishes, and as a heat-resistant barrier. Extra wide aluminum foil thickness The standard width of household aluminum foil is usually about 12 inches (30 cm). Extra-w ...

Which 8000 series alloy is more suitable for alu alu foil? For alu alu foil, aluminum foil for pharmaceutical packaging, the selection of the base material needs to take into account factors such as the barrier properties, mechanical strength, processing performance and cost of the aluminum foil. The aluminum foil base material should have excellent moisture barrier, air barrier, light-shielding properties, and ...

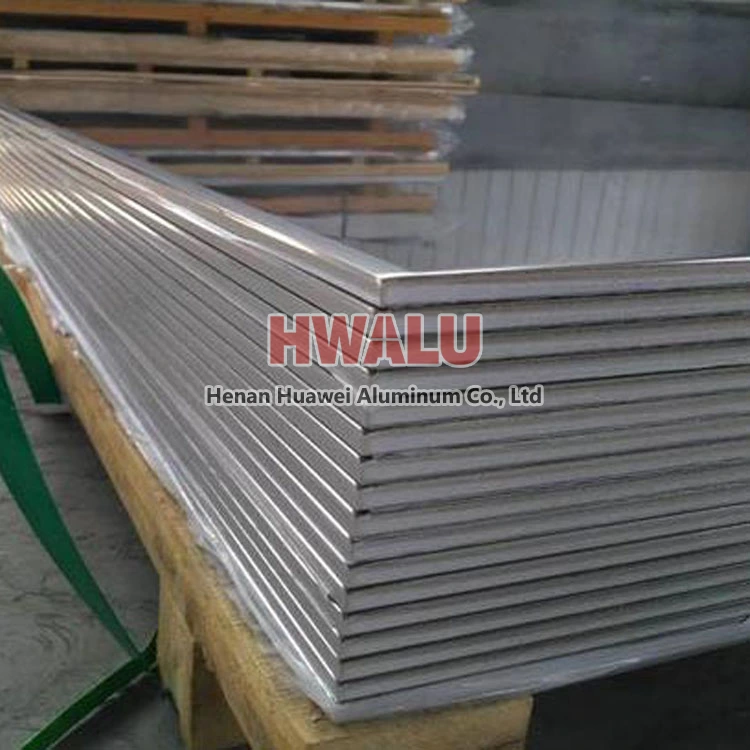

Differences Between Aluminum 5052 And Aluminum 6061 Introduction of 5052 aluminum alloy Aluminum 5052 is the most widely used aluminum alloy in the 5000 series. 5052 aluminum belongs to the A1-Mg alloy, also known as rust-proof aluminum. 5052 aluminum alloy has high strength. When magnesium is added, 5052 aluminum plate has better corrosion resistance and enhanced strength. Aluminum alloy 5052 with excellent ...

Nowadays, many female companions attach great importance to beauty and skin care. Women who are busy with their lives and work often use facial masks for skin care, which can provide sufficient nutrients for the facial skin and make the skin healthier and more energetic. With the increasing demand for facial masks, many manufacturers now make and produce facial masks. In order to improve the storage time of facia ...

The aluminum foil disposable lunch box has excellent oil and water resistance and is easy to recycle after being discarded. This kind of packaging can quickly reheat the food and keep the fresh taste of the food. 1. Performance of aluminum foil tableware and containers: All kinds of food lunch boxes produced by aluminum foil, aviation lunch boxes currently generally adopt the latest and most scientific alum ...

8011 aluminum foil is a common aluminum alloy material, which has received extensive attention and application due to its good performance and wide application fields. Below, we will introduce the characteristics and advantages of 8011 aluminum foil from various aspects. First of all, 8011 aluminum foil has excellent corrosion resistance. Aluminum foil itself has good oxidation resistance, and 8011 aluminum fo ...

As a metal material, aluminum foil is non-toxic, tasteless, has excellent electrical conductivity and light-shielding properties, extremely high moisture resistance, gas barrier properties, and its barrier performance is incomparable and irreplaceable by any other polymer materials and vapor-deposited films. of. Perhaps it is precisely because aluminum foil is a metal material completely different from plastic, i ...