What is AC aluminum foil? Air conditioning aluminum foil, often called AC foil or HVAC foil, is a type of aluminum foil used in the heating, ventilation and air conditioning (HVAC) industry. Air-conditioning aluminum foil is usually used to make heat-conducting fins for air-conditioning heat exchange and air-conditioning evaporators. It is one of the important alloys used in air conditioning manufacturing raw ma ...

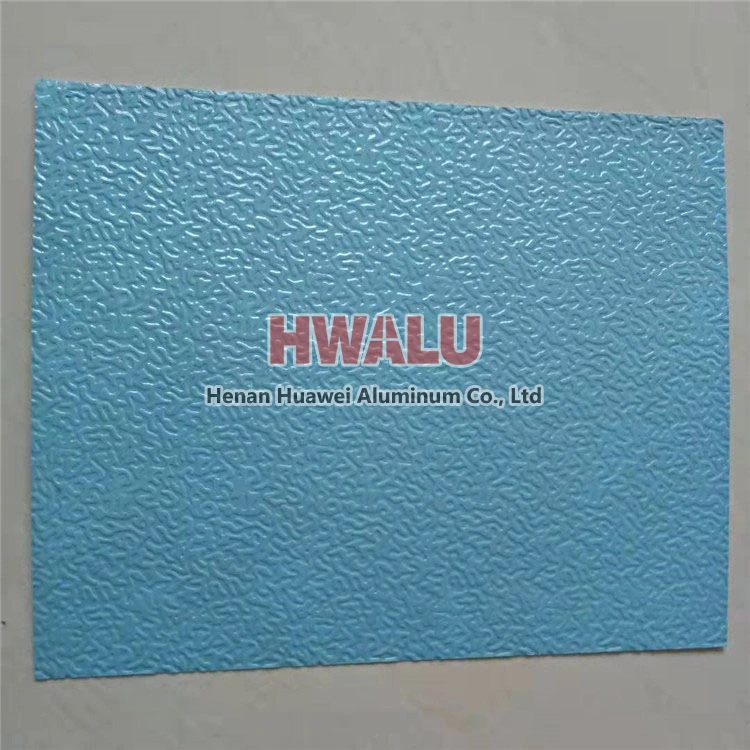

Specifications of sarin coated embossed aluminum foil Alloy model 1100 or 1200 3003 or 3004 5052, 5083, 5754 8011, 8079 Thickness 0.006mm-0.2mm Width 200mm-1600mm Flower type Common flower types include five flowers, tiger skin, pearl and so on. Coating sarin coating, color: gold, silver, red, green, blue, etc. Paper core inner diameter 76mm or 152mm Packing method w ...

what is Aluminum foil for capsule packaging? Compared with traditional capsule packaging materials, aluminum foil for capsule packaging has better moisture-proof, anti-oxidation and fresh-keeping properties, which can better protect the quality and safety of medicines. Reasons for choosing aluminum foil for capsule packaging Good moisture-proof performance: prevent the medicines in the capsules from moistu ...

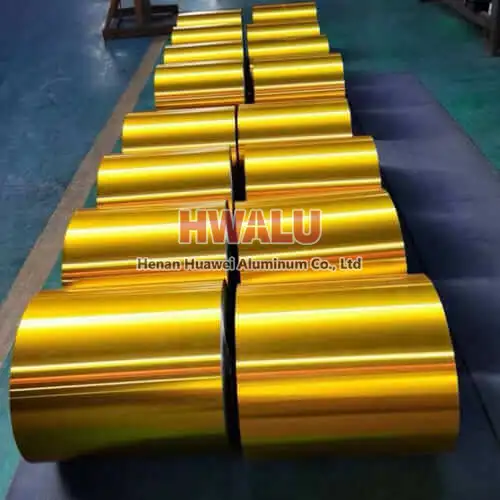

Black Gold Aluminum foil Black Gold Aluminum foil refers to aluminum foil with black or gold spray coating on the surface, and also has one side of gold and one side of very colored aluminum foil. Black aluminum foil is mostly used in aluminum foil tape, air duct materials, etc. Gold aluminum foil is widely used and is often used in chocolate packaging, pharmaceutical packaging, aluminum foil lunch box ...

Aluminum foil for grills Aluminum foil for grilling is a versatile tool used in outdoor cooking. Grill foil is a thin, flexible sheet of aluminum that can be placed over your grill grates to aid in various aspects of grilling. Advantages of aluminum foil for barbecue packaging Aluminum foil is often used for barbecue packaging and has the following advantages: 1. Thermal conductivity: Aluminum foil has ...

Aluminum foil pinhole has two main factors, one is the material, the other is the processing method. 1. Improper material and chemical composition will lead to a direct impact on the pinhole content of fake aluminum foil Fe and Si. Fe>2.5, Al and Fe intermetallic compounds tend to form coarse. Aluminum foil is prone to pinhole when calendering, Fe and Si will interact to form a firm compound. The number of ...

Aluminum foil is often used in our daily life, especially when we use microwave oven to heat food quickly. Can aluminum foil be used in microwave oven? Is it safe to do this? Please pay attention to the difference of microwave oven function, because different function mode, its heating principle is completely different, and the utensils used are also different. Now the market in addition to the microwave oven ...

Aluminum foil has a clean, hygienic and shiny appearance. It can be integrated with many other packaging materials into an integrated packaging material, and the surface printing effect of aluminum foil is better than other materials. In addition, aluminum foil has the following characteristics: (1) The surface of the aluminum foil is extremely clean and hygienic, and no bacteria or microorganisms can grow on ...

ITEM SIZE (MM) ALLOY / TEMPER WEIGHT (KGS) ALUMINIUM FOIL, ID: 76MM, ROLL LENGTH: 12000 - 13000 meters 1 0.007*1270 1235 O 18000.00

Aluminum foil jumbo roll: Ideal for cooking or baking large dishes such as roasts, turkeys or baked cakes as it covers the entire dish with ease. Ideal for wrapping leftovers or storing food in the freezer, as you can cut the desired length of foil as needed. Aluminum foil jumbo rolls can last for a long time, which can save costs in long-term use. Small rolls of aluminum foil: More portable an ...

Foil bags are not toxic. The inside of the aluminum foil insulation bag is a soft insulation material such as foam, which meets the food safety regulations. Aluminum foil has excellent barrier properties, good moisture resistance, and thermal insulation. Even if the heat reaches the middle PE airbag layer through the inner aluminum foil layer, heat convection will be formed in the middle layer, and it is not easy ...