What is aluminum foil for composite foil Aluminum foil for composite foil is an aluminum foil product used to make composite materials. Laminated foils usually consist of two or more layers of films of different materials, at least one of which is aluminum foil. These films can be bonded together using heat and pressure to form composites with multiple functions. Advantages of aluminum foil for composite foil ...

What is Yogurt Lid Foil? Yogurt Lid Foil is made of food-grade aluminum foil material, which can ensure that no harmful substances are released and is harmless to the human body. Foil yogurt lid is usually in the process of making yogurt, aluminum foil is sealed on the cup lid by special sealing equipment. Because of the good moisture resistance and oxygen barrier properties of aluminum foil, it can effective ...

What is aluminum foil for foil board Aluminum foil for foil board refers to a special type of aluminum foil used to make foil board, also known as "foil material". Foil sheets are commonly used to package food and pharmaceuticals to protect them from air, moisture, odours, light and other external elements. Aluminum foil for foil boards is usually thicker than regular aluminum foil, usually between 0.2-0.3 mm ...

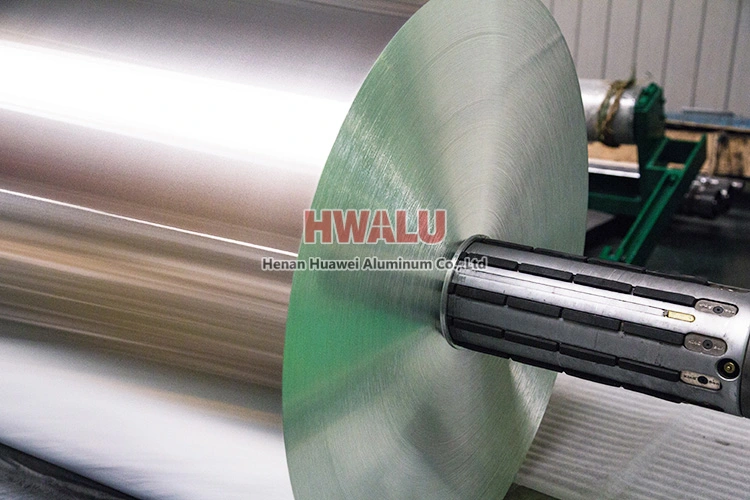

Introduction Of Best Price Aluminium Foil Roll 3003 Aluminium foil roll 3003 is a common product of Al-Mn series alloys. Because of the addition of alloy Mn element, it has excellent rust resistance, weldability and corrosion resistance. Main tempers for Aluminium foil roll 3003 are H18, H22 and H24. Similarly, 3003 aluminum foil is also a non-heat treated alloy, so a cold working method is used to improv ...

What is Aluminum Foil for Pans? Aluminum foil for pans is a type of aluminum foil specially used for cooking, and it is usually thicker and stronger than ordinary household aluminum foil, and has better heat resistance properties. It is often used to cover the bottom or sides of pans to prevent food from sticking to or scorching, while also helping to maintain moisture and nutrients in food. Aluminium foil ...

What is medicinal aluminum foil Pharmaceutical aluminum foil is generally a thinner aluminum foil, and its thickness is usually between 0.02mm and 0.03mm. The main feature of pharmaceutical aluminum foil is that it has good oxygen barrier, moisture-proof, protection and fresh-keeping properties, which can effectively protect the quality and safety of medicines. In addition, pharmaceutical aluminum foil also h ...

Aluminum foil pinhole has two main factors, one is the material, the other is the processing method. 1. Improper material and chemical composition will lead to a direct impact on the pinhole content of fake aluminum foil Fe and Si. Fe>2.5, Al and Fe intermetallic compounds tend to form coarse. Aluminum foil is prone to pinhole when calendering, Fe and Si will interact to form a firm compound. The number of ...

Product name: 8011 aluminum foil roll ID: 76MM, MAX ROLL WEIGHT: 55kg ITEM SPECIFICATION (MM) ALLOY / TEMPER 1 0.015*120 8011 O 2 0.012*120 8011 O 3 0.015*130 8011 O 4 0.015*150 8011 O ID: 76MM, MAX ROLL WEIGHT: 100 kg 5 0.015*200 8011 O

Product name: plain aluminum foil SIZE (MM) ALLOY / TEMPER 0.1MM*1220MM*200M 8011 O

Aluminum foil factories will pay special attention to the following details when processing aluminum foil: Cleaning: Aluminum foil is very sensitive to impurities, any dust, oil or other contaminants will affect the quality and performance of the aluminum foil. Therefore, before processing aluminum foil, the production workshop, equipment and tools must be thoroughly cleaned to ensure that there is no contamin ...

Nowadays, many female companions attach great importance to beauty and skin care. Women who are busy with their lives and work often use facial masks for skin care, which can provide sufficient nutrients for the facial skin and make the skin healthier and more energetic. With the increasing demand for facial masks, many manufacturers now make and produce facial masks. In order to improve the storage time of facia ...

What is PE PE refers to polyethylene (Polyethylene), which is a thermoplastic obtained by polymerization of ethylene monomers. Polyethylene has the characteristics of good chemical stability, corrosion resistance, insulation, easy processing and molding, and excellent low-temperature strength. It is a common plastic material widely used in industry and daily life. According to different preparation methods, p ...