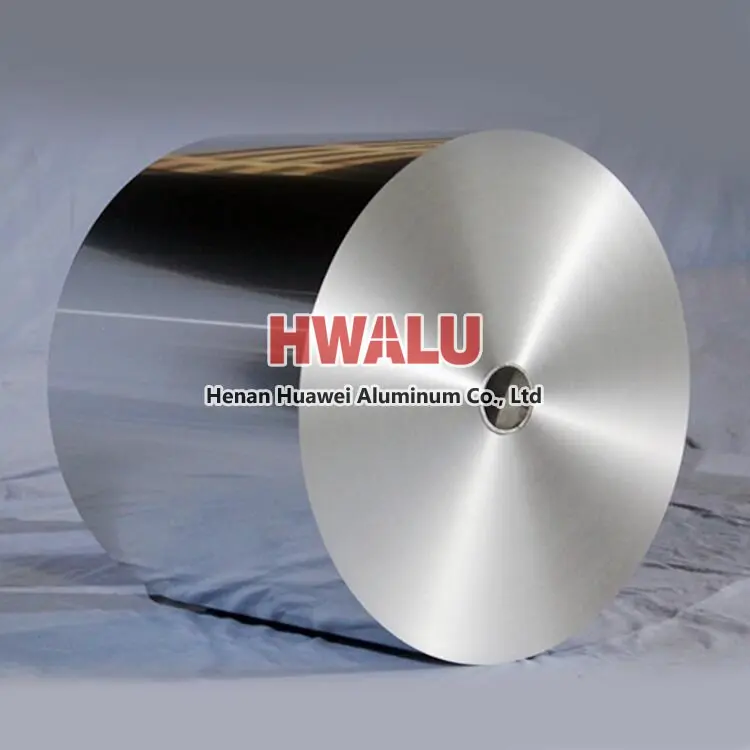

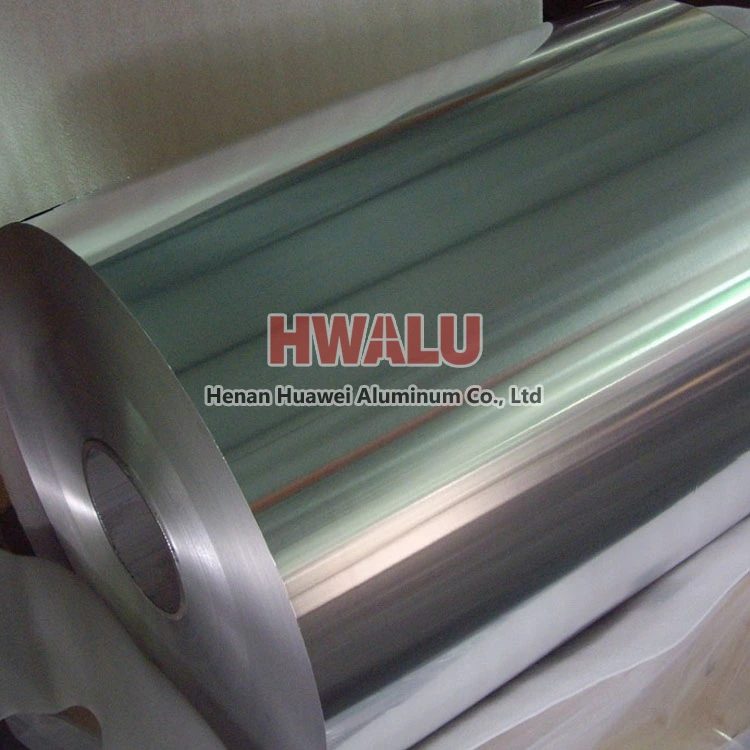

What is a large roll of aluminum foil Aluminum foil jumbo roll is a rolled product with aluminum foil as the main material, usually made of aluminium plate through multiple rolling and annealing processes. Aluminium foil jumbo rolls are usually sold in rolls, and the length and width of the rolls can be customized according to customer needs. Custom width aluminum foil jumbo roll What is the productio ...

Aluminum foil can be customized size Thickness: 0.006mm - 0.2mm Width: 200mm - 1300mm Length: 3 m - 300 m In addition, customers can also choose different shapes, colors, printing and packaging methods according to their needs. If you need custom aluminum foil, please contact us, we can provide you with options and customized services. Aluminum foil type According to the processin ...

Aluminum foil for kitchen parameters Surface Teatment: One side bright, another side dull. Printing: coloured gold, rose gold Embossed: 3d pattern Thickness: 20mts, 10 mic, 15 micron etc Sizes: 1m, 40*600cm, 40x100 cm etc Characteristics and uses of kitchen aluminum foil Aluminum foil is a versatile and commonly used kitchen item that offers a range of benefits for cooking, food storage and othe ...

Welcome to Huawei Aluminum, your trusted partner in the world of aluminum foil. We are a leading aluminum foil 8011 12-micron factory and wholesaler, committed to delivering high-quality products that cater to a wide range of industries. In this comprehensive guide, we will explore everything you need to know about our Aluminum Foil 8011, its specifications, and applications. 1. Introduction to Aluminum Foil ...

6 mic aluminum foil brief overview 6 mic aluminum foil is one of the very commonly used light gauge aluminum foil.6 mic are equal to 0.006 millimeters, known as double zero six aluminum foil in China. aluminum mic 6 properties Tensile Strength: 48 ksi (330 MPa) Yield Strength: 36 ksi (250 MPa) Hardness: 70-80 Brinell Machinability: Easy to process due to its homogeneity and low in ...

Why does hair use aluminum foil? The use of aluminum foil for hair is often done during hair coloring, especially when a specific pattern or effect is desired. Aluminum foil can help isolate and hold the hair dye in place, ensuring it only goes where it's needed, creating a more precise and detailed finish. When coloring hair, hairdressers usually divide the hair to be colored into sections and wrap each sect ...

Aluminum foil is recyclable. Due to the high purity of aluminum foil materials, they can be reprocessed into various aluminum products after recycling, such as food packaging, construction materials, etc. Recycling aluminum, meanwhile, is an energy-saving process that involves melting down aluminum scrap to create new aluminum products. Compared to producing aluminum from raw materials, the recycling process of a ...

It is a characteristic of aluminum box rolling that the thickness deviation is difficult to control. The thickness difference of 3% is not difficult to control in the production of plate and strip, but it is more difficult to control in the production of aluminum foil. As the thickness of the aluminum box becomes thinner, its micro-conditions can affect it, such as temperature, oil film, and oil and gas concen ...

The rolling oil and other oil stains remaining on the surface of the foil, which are formed on the foil surface to varying degrees after annealing, are called oil spots. The main reasons for oil spots: high degree of oil in aluminum foil rolling, or inappropriate distillation range of rolling oil; mechanical oil infiltration in aluminum foil rolling oil; improper annealing process; excessive oil on the surface ...

What is household foil? Household foil, also called household aluminum foil and commonly referred to as aluminum foil, is a thin sheet of aluminum used for a variety of household purposes. It has become a must-have for many households due to its versatility, durability, and convenience. Household aluminum foil is usually made of aluminum alloy, which combines the characteristics of pure aluminum with the adva ...

https://www.youtube.com/watch?v=ZR_JvbVongU The shocking statistics released by the National Center for Cardiovascular Diseases suggest that China has the highest occurrence of sudden cardiac deaths (SCD) in the world, accounting for over 544,000 deaths annually. That is to say, SCDs occur at a rate of 1,500 people/day or one person/minute in China. According to David Jin, general manager of Henan Huawei Alumi ...

1. Chemical composition: The alloy grades of aluminum foil for heat exchange fins mainly include 1100, 1200, 8011, 8006, etc. From the perspective of use, air conditioners do not have strict requirements on the chemical composition of aluminum heat exchange fins. Without surface treatment, 3A21 aluminum alloy has relatively good corrosion resistance, high mechanical properties such as strength and elongation, ...