what is Cold forming alu alu foil? Cold forming blister foil can absolutely resist vapor, oxygen and UV rays with good performance of aroma barrier. Each blister is a single protection unit, no effect to barrier after opening first cavity. Cold forming foil is suitable to pack drugs that easy to be affected in wet regions and tropics. It can be shaped in various appearance by changing stamping mold. Simultane ...

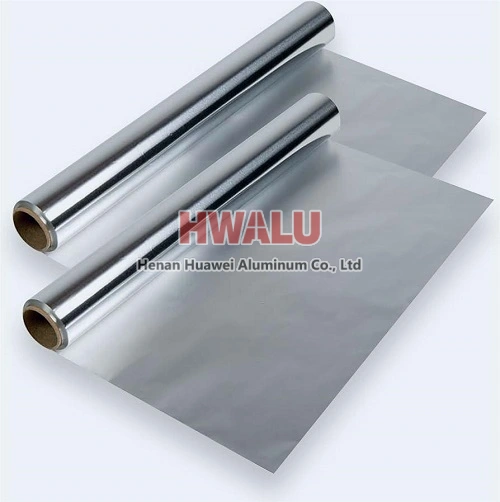

Introduction: Welcome to Huawei Aluminum, a trusted name in the aluminum industry. Our 14 Micron Aluminum Foil for Food Use is a top-quality product that serves various purposes in the food packaging and laminated materials sector. In this detailed guide, we will delve into the specifics of our 14 Micron Aluminum Foil, discussing its alloy models, specifications, applications, advantages, and more. Alloy Mo ...

Aluminum foil for grills Aluminum foil for grilling is a versatile tool used in outdoor cooking. Grill foil is a thin, flexible sheet of aluminum that can be placed over your grill grates to aid in various aspects of grilling. Advantages of aluminum foil for barbecue packaging Aluminum foil is often used for barbecue packaging and has the following advantages: 1. Thermal conductivity: Aluminum foil has ...

What Is Food Packaging Aluminium Foil Roll 8011 As we all know, aluminum foil is widely used in our daily life, especially in the field of food packaging. Aluminum foil roll 8011 is a common food packaging material. 8011 aluminum alloy is a high-quality aluminum alloy with good ductility, strength and corrosion resistance. This type of aluminum foil is commonly used for food packaging. 8011 aluminum fo ...

What is medicinal aluminum foil Pharmaceutical aluminum foil is generally a thinner aluminum foil, and its thickness is usually between 0.02mm and 0.03mm. The main feature of pharmaceutical aluminum foil is that it has good oxygen barrier, moisture-proof, protection and fresh-keeping properties, which can effectively protect the quality and safety of medicines. In addition, pharmaceutical aluminum foil also h ...

Now the aluminum foil we see in the market is no longer made of tin, because it is more expensive and less durable than aluminum. The original tin foil (also known as tin foil) is really made of tin. Tin foil is softer than aluminum foil. It will smell tinted to wrap food. At the same time, tin foil cannot be heated due to its low melting point, or the heating temperature is high-such as 160 It begins to becom ...

8006 aluminum foil is mainly used for food packaging, such as milk boxes, juice boxes, etc. 8006 aluminum foil has good corrosion resistance and mechanical properties, which can meet various packaging needs. 8011 aluminum foil is a common aluminum alloy material, mainly used in food packaging and pharmaceutical packaging. 8011 aluminum foil has good waterproof, moisture-proof and oxidation-proof properties, an ...

The post-processing of aluminum foil is an important part of an enterprise, which is related to the yield of an aluminum enterprise and the profit point of the enterprise. The higher the yield, the higher the profit point of the enterprise. Of course, the yield rate must be controlled in every link, standardized operation, and sophisticated equipment and responsible leaders and employees are required. I don't und ...

Anodized Aluminum Foil Overview Anodized aluminum foil is aluminum foil that has been anodized. Anodizing is an electrochemical process in which aluminum foil is immersed in an electrolyte solution and an electric current is applied. This causes oxygen ions to bond with the aluminum surface, forming a layer of aluminum oxide. It can increase the thickness of the natural oxide layer on the aluminum surface. This ...

Aluminum foil is often used in our daily life, especially when we use microwave oven to heat food quickly. Can aluminum foil be used in microwave oven? Is it safe to do this? Please pay attention to the difference of microwave oven function, because different function mode, its heating principle is completely different, and the utensils used are also different. Now the market in addition to the microwave oven ...

1. Chemical composition: The alloy grades of aluminum foil for heat exchange fins mainly include 1100, 1200, 8011, 8006, etc. From the perspective of use, air conditioners do not have strict requirements on the chemical composition of aluminum heat exchange fins. Without surface treatment, 3A21 aluminum alloy has relatively good corrosion resistance, high mechanical properties such as strength and elongation, ...