Aluminum foil for battery Alloy 1070、1060、1050、1145、1235、1100 Temper -O、H14、-H24、-H22、-H18 Thickness 0.035mm - 0.055mm Width 90mm - 1500mm What is Battery aluminum foil? Battery aluminum foil is used as a collector for lithium-ion batteries. Typically, the lithium ion battery industry uses rolled aluminum foil as a positive collector. Product features: 1. Aluminum ...

Alloy parameters of aluminum foil for labels Alloy type: 1xxx, 3xxx, 8xxx Thickness: 0.01mm-0.2mm Width: 100mm-800mm Hardness: To ensure the stability and processability of the label. Surface treatment: Coating or painting treatment to improve the corrosion resistance and aesthetics of the label. Alloy type of aluminum foil for labels 1050, 1060, 1100 With high purity ...

What is 13 micron aluminum foil? "Aluminum Foil 13 Micron" is a thin and light aluminum foil that falls within the thickness range of household aluminum foil and is commonly used for various packaging and insulation purposes. It is a very common thickness specification. 13 micron aluminum foil equivalent name 13μm aluminum foil 0.013mm aluminum foil Household packaging aluminum foil 13 micron aluminum foil ...

Aluminum foil for disposable tableware Today, with the rapid economic development and the continuous improvement of the quality of life, aluminum foil for disposable tableware is used more and more frequently in daily life. Reasons for aluminum foil for disposable tableware Aluminum foil for disposable tableware can be waterproof, maintain freshness, prevent bacteria and stains, and maintain flavor and freshne ...

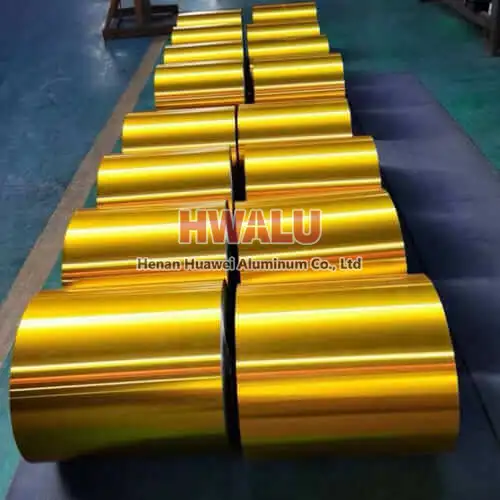

Black Gold Aluminum foil Black Gold Aluminum foil refers to aluminum foil with black or gold spray coating on the surface, and also has one side of gold and one side of very colored aluminum foil. Black aluminum foil is mostly used in aluminum foil tape, air duct materials, etc. Gold aluminum foil is widely used and is often used in chocolate packaging, pharmaceutical packaging, aluminum foil lunch box ...

Advantages and main applications of aluminum foil food packaging Aluminum foil food packaging is beautiful, lightweight, easy to process, and easy to recycle; aluminum foil packaging is safe, hygienic, and helps maintain the aroma of food. It can keep food fresh for a long time and provide protection from light, ultraviolet rays, grease, water vapor, oxygen and microorganisms. In addition, please be aware of th ...

It is generally believed that the single-sheet rolling speed of the aluminum foil should reach 80% of the rolling design speed of the rolling mill. Danyang Aluminum Company introduced a 1500 mm four-high irreversible aluminum foil roughing mill from Germany ACIIENACH. The design speed is 2 000 m/min. At present, the single-sheet aluminum foil rolling speed is basically at the level of 600m/miT, and the domestic s ...

Product name: industrial aluminum foil roll Item Specification (mm) Description ALUMINUM FOIL ROLLS WITH SUPPORT FOR INDUSTRIAL USE 8011-O, 0. 014 (+/-4%) *300 (+/-1mm). Outside -matt Inside - bright ID 152 OD min 450, Max 600. Elongation - min 2% Tensile strength - min 80, max 130MPa. Porosity - max 30 pcs per 1m2. Wettability - A. Splices - maximum 1 splice per ...

What is PE PE refers to polyethylene (Polyethylene), which is a thermoplastic obtained by polymerization of ethylene monomers. Polyethylene has the characteristics of good chemical stability, corrosion resistance, insulation, easy processing and molding, and excellent low-temperature strength. It is a common plastic material widely used in industry and daily life. According to different preparation methods, p ...

People are stepping up the search for safer, lower cost, more powerful battery systems that outperform lithium-ion batteries, so aluminum foil has also become a material for making batteries. Aluminum foil can be used in batteries in some cases, especially as an integral part of the battery structure. Aluminum foil is commonly used as a current collector for various types of batteries, including lithium-ion an ...

The rolling oil and other oil stains remaining on the surface of the foil, which are formed on the foil surface to varying degrees after annealing, are called oil spots. The main reasons for oil spots: high degree of oil in aluminum foil rolling, or inappropriate distillation range of rolling oil; mechanical oil infiltration in aluminum foil rolling oil; improper annealing process; excessive oil on the surface ...

Aluminum foil plays a vital role in the construction of lithium-ion batteries. There are many models in the 1000-8000 series alloys that can be used in battery production. Pure aluminum foil: Pure aluminum foil commonly used in lithium batteries includes various alloy grades such as 1060, 1050, 1145, and 1235. These foils are usually in different states such as O, H14, H18, H24, H22. Especially alloy 1145. ...