Pharmaceutical easy-tear aluminum strip foil Pharmaceutical easy-tear aluminum strip foil is a common pharmaceutical packaging material, usually used to package pharmaceuticals such as oral tablets and capsules. It has the advantages of easy tearing, good sealing, moisture resistance, and oxidation resistance, which can effectively protect the quality and safety of medicines. Pharmaceutical easy-tear aluminum ...

what is Aluminum Foil For Microwave Oven It is commonly used to cover or wrap food items during microwave cooking, reheating, or defrosting to prevent moisture loss, splattering, and to promote even heating. However, it is important to note that not all aluminum foil is safe for use in microwave ovens. Regular aluminum foil can cause sparks and potentially damage the microwave oven, or even start a fire. Ther ...

Introduction of 8011 alloy aluminum foil 8011 alloy aluminum foil is added Al-Fe-Si elements, more than 1% of the total alloying elements in the corresponding performance of its alloy has a higher advantage, mainly for food packaging, and pharmaceutical packaging. Machinable range of thickness: 0.02mm-0.07mm, width 300mm-1100mm, can be customized according to customer needs. General parameters of aluminu ...

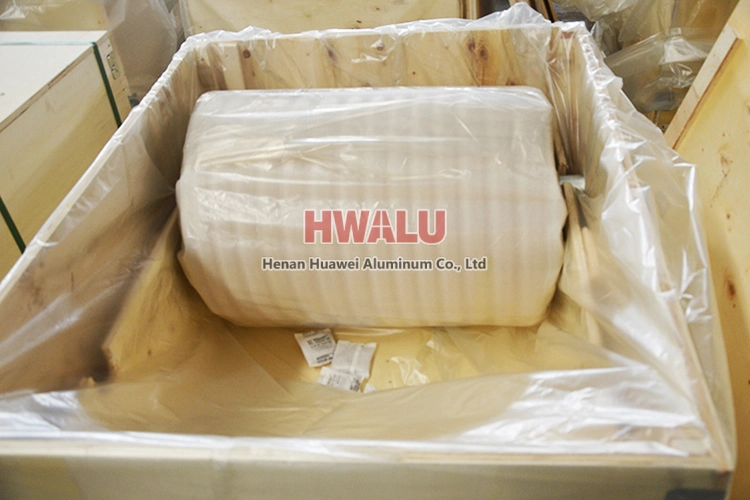

What is a large roll of aluminum foil Aluminum foil jumbo roll is a rolled product with aluminum foil as the main material, usually made of aluminium plate through multiple rolling and annealing processes. Aluminium foil jumbo rolls are usually sold in rolls, and the length and width of the rolls can be customized according to customer needs. Custom width aluminum foil jumbo roll What is the productio ...

what is Cold forming alu alu foil? Cold forming blister foil can absolutely resist vapor, oxygen and UV rays with good performance of aroma barrier. Each blister is a single protection unit, no effect to barrier after opening first cavity. Cold forming foil is suitable to pack drugs that easy to be affected in wet regions and tropics. It can be shaped in various appearance by changing stamping mold. Simultane ...

Pre-coated aluminum foil used for punching various containers, commonly used alloy 8011, 3003, 3004, 1145, etc., thickness is 0.02-0.08mm. Oiling thickness is 150-400mg/m². The use of aluminum foil as a semi-rigid container to hold food has been widely adopted at home and abroad. With the continuous development of the national economy and the continuous improvement of people’s living standards, people’s health ...

Product name: plain aluminum foil SIZE (MM) ALLOY / TEMPER 0.1MM*1220MM*200M 8011 O

In the production of double foil, the rolling of aluminum foil is divided into three processes: rough rolling, intermediate rolling, and finishing rolling. From a technological point of view, it can be roughly divided from the thickness of the rolling exit. The general method is that the exit thickness is greater than Or equal to 0.05mm is rough rolling, the exit thickness is between 0.013 and 0.05 is intermediat ...

Can aluminum foil be used to wrap chocolate?Aluminum foil can be used to wrap chocolate, thanks to its properties. In fact, aluminum foil packaging of chocolate is a common and practical method of packaging and preserving chocolate. Aluminum foil is suitable for packaging chocolate for the following reasons: Barrier properties: Aluminum foil effectively blocks moisture, air, light and odors. Helps protect c ...

Aluminum foil plays a vital role in the construction of lithium-ion batteries. There are many models in the 1000-8000 series alloys that can be used in battery production. Pure aluminum foil: Pure aluminum foil commonly used in lithium batteries includes various alloy grades such as 1060, 1050, 1145, and 1235. These foils are usually in different states such as O, H14, H18, H24, H22. Especially alloy 1145. ...

In recent years, Huawei Aluminum Co., Ltd. has set up a special research team under the condition that the aluminum foil rolling mill backing roll and the inner ring of the backing roll bearing are tight, to maintain production by repairing the scrapped backing rolls, and to ensure the normal operation of the seven aluminum foil rolling mills. During the repair process, the research team was able to repair, explo ...