What is Aluminum Foil for Condenser Fins Aluminum foil for condenser fins is a material used in the manufacture of condensers. A condenser is a device that cools a gas or vapor into a liquid and is commonly used in refrigeration, air conditioning, automotive and industrial applications. Fins are an important part of the condenser, and their function is to increase the cooling area and heat exchange efficiency, m ...

What is Yogurt Lid Foil? Yogurt Lid Foil is made of food-grade aluminum foil material, which can ensure that no harmful substances are released and is harmless to the human body. Foil yogurt lid is usually in the process of making yogurt, aluminum foil is sealed on the cup lid by special sealing equipment. Because of the good moisture resistance and oxygen barrier properties of aluminum foil, it can effective ...

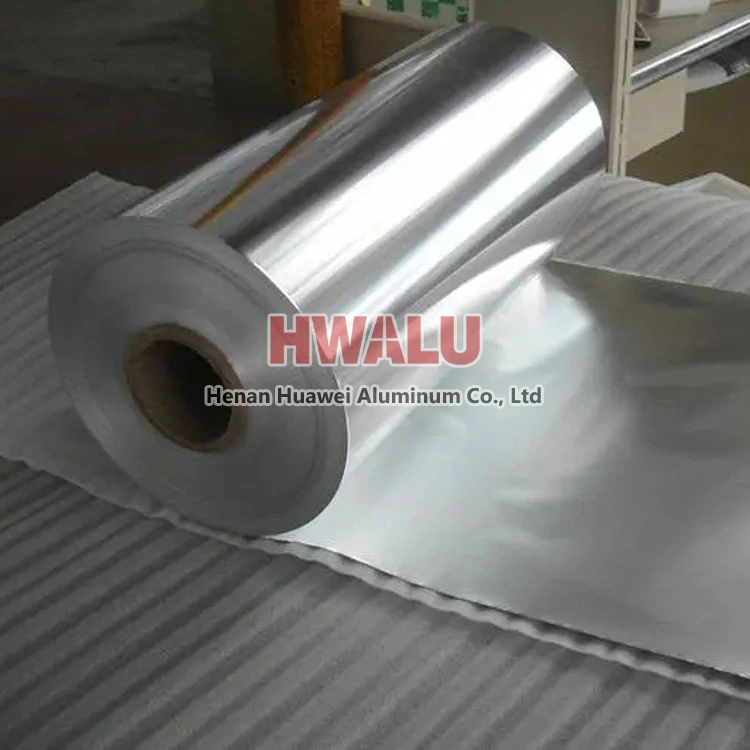

What is Aluminum Foil? Aluminum Foil Roll Aluminum foil roll for aluminum foil refers to a raw material used to produce aluminum foil, usually an aluminum foil roll with a certain width and length. Aluminum foil is a very thin aluminum material, its thickness is usually between 0.005 mm and 0.2 mm, and it has good electrical and thermal conductivity and corrosion resistance. Aluminum foil jumbo rolling Aluminu ...

aluminium foil specification Aluminum foil for coated foil Coated Products gauges/thicknesses 0.00035” - .010” Coating thicknesses .002″ Width .250” - 54.50” Length customize aluminum foil for coated foil We offer a variety of Coated Products Carbon coated aluminum foil Heat Seals Corrosion Resistant Epoxies Slip Lubes Print Primers Release Coatings, ...

what is 1100 alloy aluminum foil 1100 alloy aluminum foil is a type of aluminum foil made from 99% pure aluminum. It is commonly used in various applications such as packaging, insulation, and electronics because of its excellent corrosion resistance, high thermal conductivity, and good electrical conductivity. 1100 alloy aluminum foil is soft and ductile, making it easy to work with and shape. It can be easi ...

The main factors affecting the heat sealing strength of aluminum foil medicine packaging are as follows: 1. Raw and auxiliary materials The original aluminum foil is the carrier of the adhesive layer, and its quality has a great influence on the heat seal strength of the product. In particular, oil stains on the surface of the original aluminum foil will weaken the adhesion between the adhesive and the orig ...

Aluminum foil is recyclable. Due to the high purity of aluminum foil materials, they can be reprocessed into various aluminum products after recycling, such as food packaging, construction materials, etc. Recycling aluminum, meanwhile, is an energy-saving process that involves melting down aluminum scrap to create new aluminum products. Compared to producing aluminum from raw materials, the recycling process of a ...

Household foil is widely used in cooking, freezing, preservation, baking and other industries. The disposable aluminum foil paper has the advantages of convenient use, safety, sanitation, no odor and no leakage. In the refrigerator or freezer, aluminum foil can be directly wrapped on the food, which can keep the food from deformation, avoid the water loss of fish, vegetables, fruits and dishes, and prevent the le ...

The thickness of aluminum foil for food packaging is generally between 0.015-0.03 mm. The exact thickness of aluminum foil you choose depends on the type of food being packaged and the desired shelf life. For food that needs to be stored for a long time, it is recommended to choose thicker aluminum foil, such as 0.02-0.03 mm, to provide better protection against oxygen, water, moisture and ultraviolet rays, th ...

1. Chemical composition: The alloy grades of aluminum foil for heat exchange fins mainly include 1100, 1200, 8011, 8006, etc. From the perspective of use, air conditioners do not have strict requirements on the chemical composition of aluminum heat exchange fins. Without surface treatment, 3A21 aluminum alloy has relatively good corrosion resistance, high mechanical properties such as strength and elongation, ...

Material selection: The material of aluminum foil should be high-purity aluminum without impurities. Choosing good quality materials can guarantee the quality and service life of aluminum foil. Parent roll surface treatment: In the early stage of aluminum foil production, the surface of the parent roll needs to be cleaned and decontaminated to ensure a smooth and flat surface and avoid oxide layers and ble ...