Double zero aluminum foil refers to aluminum foil with a thickness between 0.001mm ( 1 micron ) and 0.01mm ( 10 micron ). Such as 0.001mm ( 1 micron ), 0.002mm ( 2 micron ), 0.003mm ( 3 micron ), 0.004mm ( 4 micron ), 0.005mm ( 5 micron ), 0.006mm ( 6 micron ), 0.007mm ( 7 micron ), 0.008mm ( 8 micron ), 0.009mm ( 9 micron ) 0.005 mic aluminium foil Advantages of 0.001-0.01 micron aluminum foil An ...

What is Aluminum Foil for Electricians Electrical aluminum foil is a special type of aluminum foil that is coated with an insulating material and is commonly used in electrical insulation applications. Its insulating layer prevents the loss of current from the surface of the aluminum foil while protecting the foil from the external environment. This aluminum foil usually requires high purity, uniformity, a ...

What is aluminum foil for baking? Aluminum foil for baking is a type of aluminum foil that is commonly used in cooking and baking to wrap, cover, or line various types of food items. It is made from a thin sheet of aluminum that is rolled out and then processed through a series of rollers to achieve the desired thickness and strength. Aluminum foil for baking is typically designed to be non-stick and heat-res ...

What is medicinal aluminum foil Pharmaceutical aluminum foil is generally a thinner aluminum foil, and its thickness is usually between 0.02mm and 0.03mm. The main feature of pharmaceutical aluminum foil is that it has good oxygen barrier, moisture-proof, protection and fresh-keeping properties, which can effectively protect the quality and safety of medicines. In addition, pharmaceutical aluminum foil also h ...

Welcome to Huawei Aluminum, your trusted partner in the world of aluminum foil. We are a leading aluminum foil 8011 12-micron factory and wholesaler, committed to delivering high-quality products that cater to a wide range of industries. In this comprehensive guide, we will explore everything you need to know about our Aluminum Foil 8011, its specifications, and applications. 1. Introduction to Aluminum Foil ...

What is the difference between aluminum foil and tin foil? Can it be used for oven heating? Is aluminum foil toxic when heated? 1. Different properties: Aluminum foil paper is made of metal aluminum or aluminum alloy through rolling equipment, and the thickness is less than 0.025mm. Tin foil is made of metal tin through rolling equipment. 2. The melting point is different: the melting point of aluminum foil ...

Pre-coated aluminum foil used for punching various containers, commonly used alloy 8011, 3003, 3004, 1145, etc., thickness is 0.02-0.08mm. Oiling thickness is 150-400mg/m². The use of aluminum foil as a semi-rigid container to hold food has been widely adopted at home and abroad. With the continuous development of the national economy and the continuous improvement of people’s living standards, people’s health ...

Aluminum foil pinhole has two main factors, one is the material, the other is the processing method. 1. Improper material and chemical composition will lead to a direct impact on the pinhole content of fake aluminum foil Fe and Si. Fe>2.5, Al and Fe intermetallic compounds tend to form coarse. Aluminum foil is prone to pinhole when calendering, Fe and Si will interact to form a firm compound. The number of ...

It is generally believed that the single-sheet rolling speed of the aluminum foil should reach 80% of the rolling design speed of the rolling mill. Danyang Aluminum Company introduced a 1500 mm four-high irreversible aluminum foil roughing mill from Germany ACIIENACH. The design speed is 2 000 m/min. At present, the single-sheet aluminum foil rolling speed is basically at the level of 600m/miT, and the domestic s ...

0.03mm thick aluminum foil, which is very thin, has a variety of potential uses due to its properties. Some common applications of 0.03mm thick aluminum foil include: 1. Packaging: This thin aluminum foil is often used for packaging purposes such as wrapping food items, covering containers, and protecting products from moisture, light, and contaminants. 2. Insulation: It can be used as a thin layer of insul ...

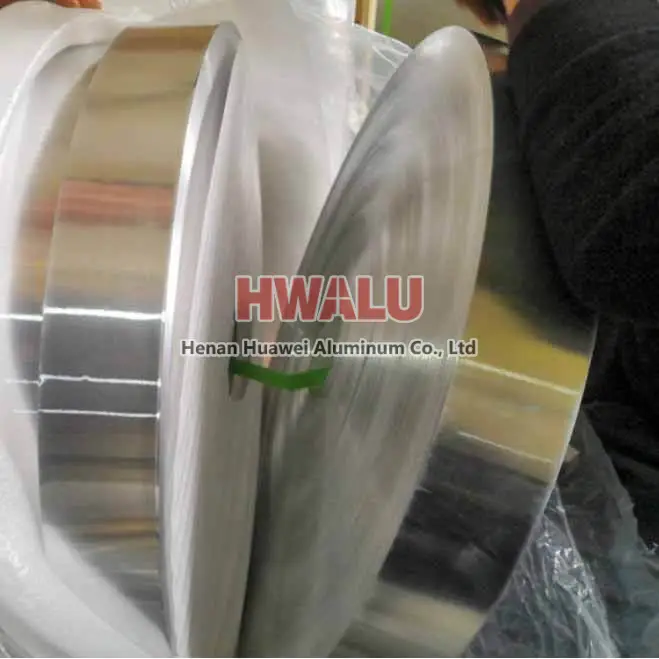

After printing and coating, aluminum foil paper and cash register paper need to be post-printed and slit on a slitting machine to cut large rolls of semi-finished products into the required specifications. The semi-finished products that run on the slitting machine are an unwinding and rewinding. This process includes two parts: machine speed control and tension control. The so-called tension is to pull the al ...