What is Aluminum Foil Tape? Aluminum foil tape is a tape based on aluminum foil, which is divided into the single-sided tape and double-sided tape; it can also be divided into conductive tape and non-conductive tape; conductive tape can also be divided into the unidirectional conductive tape and anisotropic conductive tape; It is divided into ordinary aluminum foil tape and high-temperature resistant aluminum fo ...

Alloy parameters of aluminum foil for labels Alloy type: 1xxx, 3xxx, 8xxx Thickness: 0.01mm-0.2mm Width: 100mm-800mm Hardness: To ensure the stability and processability of the label. Surface treatment: Coating or painting treatment to improve the corrosion resistance and aesthetics of the label. Alloy type of aluminum foil for labels 1050, 1060, 1100 With high purity ...

What is aluminum foil for pill packaging Aluminum foil for pill packaging is a kind of aluminum foil used for pharmaceutical packaging. This aluminum foil is usually very thin and has properties such as waterproof, anti-oxidation and anti-light, which can effectively protect the pills from external influences such as moisture, oxygen and light. Aluminum foil for pill packaging usually has the following advantage ...

In addition to cigarette packaging, the applications of aluminum foil in the packaging industry mainly include: aluminum-plastic composite bags, pharmaceutical aluminum foil blister packaging and chocolate packaging. Some high-end beers are also wrapped in aluminum foil on the bottle mouth. Medical packaging Medicinal blister packaging includes medicinal aluminum foil, PVC plastic rigid sheet, heat-sealing pain ...

What is aluminum foil for composite foil Aluminum foil for composite foil is an aluminum foil product used to make composite materials. Laminated foils usually consist of two or more layers of films of different materials, at least one of which is aluminum foil. These films can be bonded together using heat and pressure to form composites with multiple functions. Advantages of aluminum foil for composite foil ...

What is Aluminum Foil for Pans? Aluminum foil for pans is a type of aluminum foil specially used for cooking, and it is usually thicker and stronger than ordinary household aluminum foil, and has better heat resistance properties. It is often used to cover the bottom or sides of pans to prevent food from sticking to or scorching, while also helping to maintain moisture and nutrients in food. Aluminium foil ...

The biggest feature of aluminum foil is its light weight and wide range of uses, suitable for aviation, construction, decoration, industry and other industries. Aluminum is very cost-effective, and its electrical conductivity is second only to that of copper, but the price is much cheaper than that of copper, so many people now choose aluminum as the main material for wires. 1060, 3003, 5052 are several common ...

1. Chemical composition: The alloy grades of aluminum foil for heat exchange fins mainly include 1100, 1200, 8011, 8006, etc. From the perspective of use, air conditioners do not have strict requirements on the chemical composition of aluminum heat exchange fins. Without surface treatment, 3A21 aluminum alloy has relatively good corrosion resistance, high mechanical properties such as strength and elongation, ...

The rolling oil and other oil stains remaining on the surface of the foil, which are formed on the foil surface to varying degrees after annealing, are called oil spots. The main reasons for oil spots: high degree of oil in aluminum foil rolling, or inappropriate distillation range of rolling oil; mechanical oil infiltration in aluminum foil rolling oil; improper annealing process; excessive oil on the surface ...

Which 8000 series alloy is more suitable for alu alu foil? For alu alu foil, aluminum foil for pharmaceutical packaging, the selection of the base material needs to take into account factors such as the barrier properties, mechanical strength, processing performance and cost of the aluminum foil. The aluminum foil base material should have excellent moisture barrier, air barrier, light-shielding properties, and ...

Aluminum foil is a thin sheet of aluminum metal that has the following properties: Lightweight: Aluminum foil is very lightweight because aluminium metal itself is a lightweight material. This makes aluminum foil an ideal material during packaging and shipping. Good sealing: The surface of aluminum foil is very smooth, which can effectively prevent the penetration of oxygen, water vapor and other gases, s ...

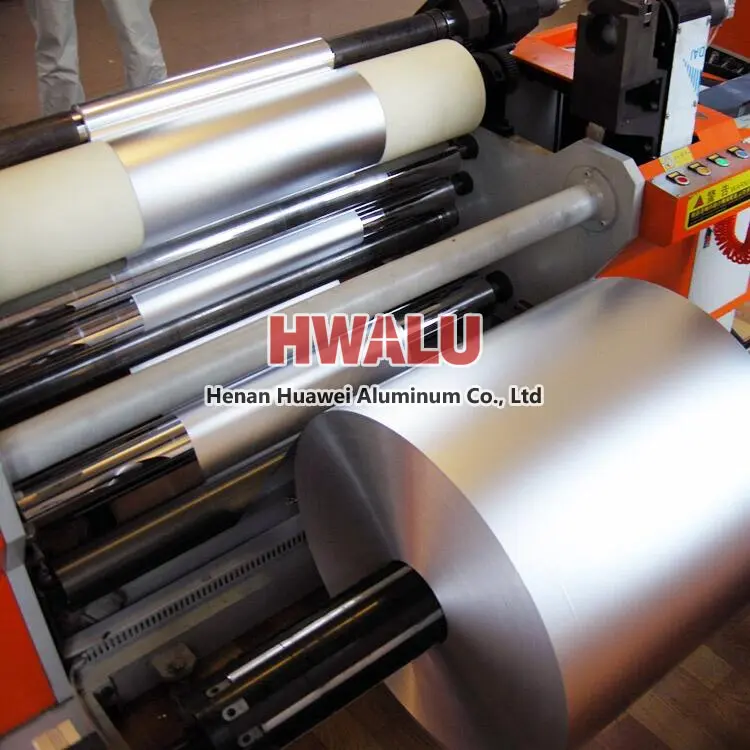

It is a characteristic of aluminum box rolling that the thickness deviation is difficult to control. The thickness difference of 3% is not difficult to control in the production of plate and strip, but it is more difficult to control in the production of aluminum foil. As the thickness of the aluminum box becomes thinner, its micro-conditions can affect it, such as temperature, oil film, and oil and gas concen ...