6 mic aluminum foil brief overview 6 mic aluminum foil is one of the very commonly used light gauge aluminum foil.6 mic are equal to 0.006 millimeters, known as double zero six aluminum foil in China. aluminum mic 6 properties Tensile Strength: 48 ksi (330 MPa) Yield Strength: 36 ksi (250 MPa) Hardness: 70-80 Brinell Machinability: Easy to process due to its homogeneity and low in ...

What is bright aluminum foil? Bright aluminum foil is a kind of aluminum foil material with a smooth surface and good reflective properties. It is usually made of high-purity aluminum metal material through multiple precision machining processes. In the manufacturing process, aluminum metal is rolled into very thin sheets, which are then specially treated The rollers are repeatedly rolled until the surfac ...

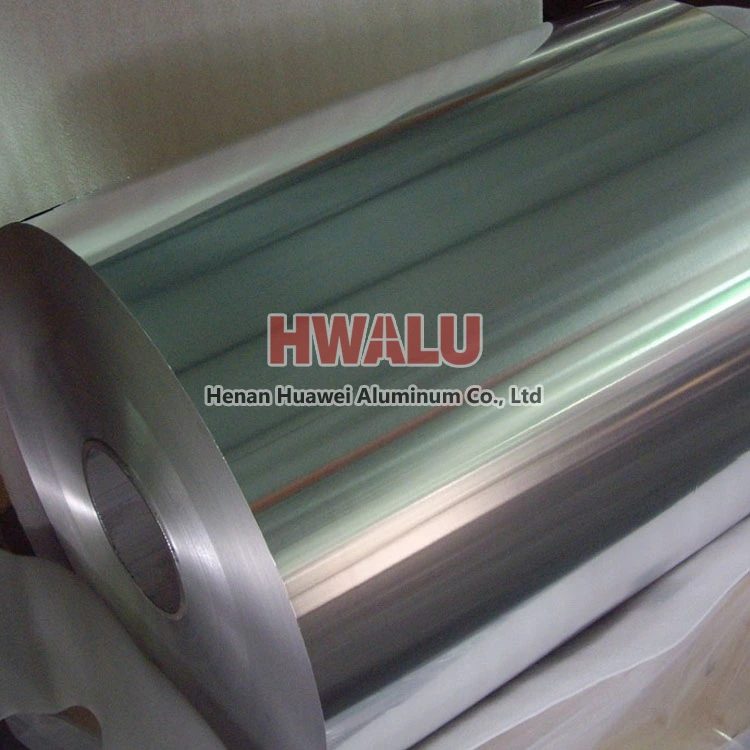

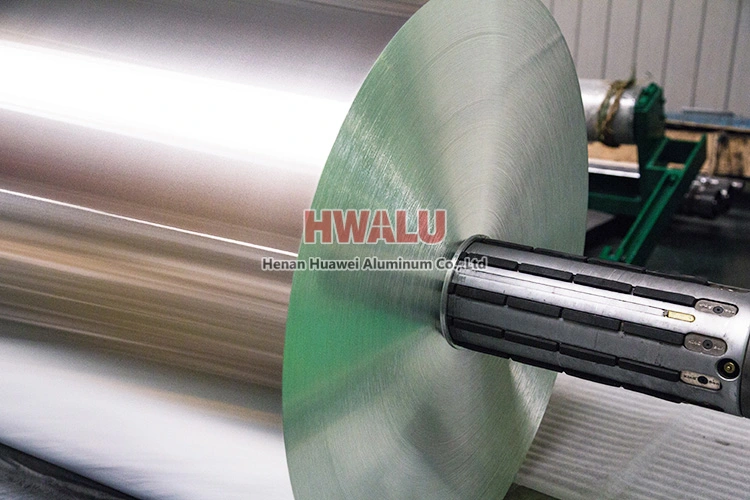

What is a large roll of aluminum foil Aluminum foil jumbo roll is a rolled product with aluminum foil as the main material, usually made of aluminium plate through multiple rolling and annealing processes. Aluminium foil jumbo rolls are usually sold in rolls, and the length and width of the rolls can be customized according to customer needs. Custom width aluminum foil jumbo roll What is the productio ...

Cigarette aluminum foil parameters Alloy: 3004 8001 Thickness: 0.018-0.2mm Length: can be customized according to customer needs Surface: One side has a high light emissivity, and the other side has a soft matt finish. what is the metallic paper in a cigarette box The metallic paper in cigarette packs is aluminum foil. One is to keep fragrance. Aluminum foil can prevent the smell of cigarette ...

Aluminum foil for battery Alloy 1070、1060、1050、1145、1235、1100 Temper -O、H14、-H24、-H22、-H18 Thickness 0.035mm - 0.055mm Width 90mm - 1500mm What is Battery aluminum foil? Battery aluminum foil is used as a collector for lithium-ion batteries. Typically, the lithium ion battery industry uses rolled aluminum foil as a positive collector. Product features: 1. Aluminum ...

Product name: 8011 aluminum foil roll ID: 76MM, MAX ROLL WEIGHT: 55kg ITEM SPECIFICATION (MM) ALLOY / TEMPER 1 0.015*120 8011 O 2 0.012*120 8011 O 3 0.015*130 8011 O 4 0.015*150 8011 O ID: 76MM, MAX ROLL WEIGHT: 100 kg 5 0.015*200 8011 O

▌ Make bananas last longer Like avocados, bananas can go from underripe to overripe in the blink of an eye. This is because bananas release a gas called ethylene to ripen, and the stem is where the most ethylene is released. One way to prevent bananas from ripening too quickly is to wrap a small piece of aluminum foil around the stem. ▌ Polishing chrome with aluminum foil It can be used in places ...

Product name: plain aluminum foil SIZE (MM) ALLOY / TEMPER 0.1MM*1220MM*200M 8011 O

Aluminum foil jumbo roll: Ideal for cooking or baking large dishes such as roasts, turkeys or baked cakes as it covers the entire dish with ease. Ideal for wrapping leftovers or storing food in the freezer, as you can cut the desired length of foil as needed. Aluminum foil jumbo rolls can last for a long time, which can save costs in long-term use. Small rolls of aluminum foil: More portable an ...

Aluminum foil and aluminum coil are both versatile aluminum alloy materials used in different applications across various industries. Aluminum coil alloy and aluminum foil alloy have similar properties in many aspects, but also have many different characteristics. Huawei will make a detailed comparison between the two in terms of properties, uses, etc.: What are aluminum coils and aluminum foil? Aluminum Foil: ...

Aluminum alloy 1350, often referred to as "1350 aluminum foil", is a pure aluminum alloy with a minimum aluminum content of 99.5%. While pure aluminum is not commonly used in pharmaceutical packaging, aluminum and its alloys (including 1350 aluminum) can be used in pharmaceutical packaging after proper processing and coating. Pharmaceutical packaging requires certain properties to ensure the safety and preserv ...