Introduction: At Huawei Aluminum, we take pride in being a leading manufacturer and wholesaler of high-quality aluminum foil paper designed specifically for food containers. With a commitment to excellence and precision, our 3003 Aluminum foil is engineered to meet the highest industry standards, ensuring the safety and reliability of your food packaging. Why Choose 3003 Aluminum for Food Containers? The c ...

Aluminum foil for grills Aluminum foil for grilling is a versatile tool used in outdoor cooking. Grill foil is a thin, flexible sheet of aluminum that can be placed over your grill grates to aid in various aspects of grilling. Advantages of aluminum foil for barbecue packaging Aluminum foil is often used for barbecue packaging and has the following advantages: 1. Thermal conductivity: Aluminum foil has ...

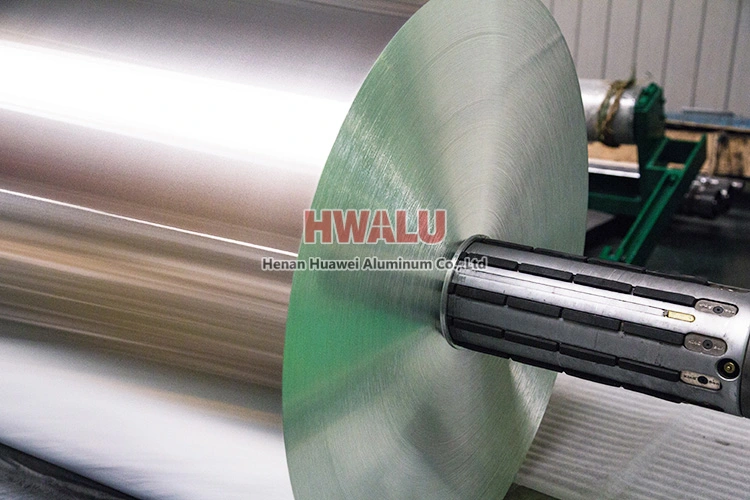

Aluminum foil parameters Raw Material 1235, 3003, 8011 etc Alloy Temper O, H28, etc Thickness 6.5 micron, 10 microns, 11micron( 11 microns), 20micron, 130-250mic ( for laminated foil cold forming ) Size 3000m, 80 cm, etc We can provide jumbo roll aluminum foil Product Name Alloy Temper Thickness or Gauge(mm ) Width(mm ) Surface Finishing Use Aluminum Foil For Foo ...

Introduction of 8079 alloy aluminum foil What is aluminum foil grade 8079? 8079 alloy aluminum foil usually used to produce kinds of aluminum alloy foil, which offers the best properties for many applications with H14, H18 and other tempers and thicknesses between 10 and 200 microns. The tensile strength and elongation of alloy 8079 are higher than other alloys, so it is not flexible and moisture resistant. ...

what is 8021 alloy aluminum foil? 8021 alloy aluminum foil has excellent moisture resistance, shading, and extremely high barrier ability: elongation, puncture resistance, and strong sealing performance. The aluminum foil after compounding, printing, and gluing is widely used as a packaging material. Mainly used for food packaging, blister drug packaging, soft battery packs, etc. The Advantages Of 8021 a ...

Aluminum foil lunch box is not a new thing, but it is really the last two or three years is particularly active. In particular, the hot sealing aluminum foil lunch box, because it is the first sealed food and then high-temperature cooking disinfection, in the consumer to open the taste before the maximum ensure food safety and health, full tightness, and high barrier can also be a good lock food flavor. Even i ...

0.03mm thick aluminum foil, which is very thin, has a variety of potential uses due to its properties. Some common applications of 0.03mm thick aluminum foil include: 1. Packaging: This thin aluminum foil is often used for packaging purposes such as wrapping food items, covering containers, and protecting products from moisture, light, and contaminants. 2. Insulation: It can be used as a thin layer of insul ...

People are stepping up the search for safer, lower cost, more powerful battery systems that outperform lithium-ion batteries, so aluminum foil has also become a material for making batteries. Aluminum foil can be used in batteries in some cases, especially as an integral part of the battery structure. Aluminum foil is commonly used as a current collector for various types of batteries, including lithium-ion an ...

Nowadays, many female companions attach great importance to beauty and skin care. Women who are busy with their lives and work often use facial masks for skin care, which can provide sufficient nutrients for the facial skin and make the skin healthier and more energetic. With the increasing demand for facial masks, many manufacturers now make and produce facial masks. In order to improve the storage time of facia ...

Product name: 8011 aluminum foil roll ID: 76MM, MAX ROLL WEIGHT: 55kg ITEM SPECIFICATION (MM) ALLOY / TEMPER 1 0.015*120 8011 O 2 0.012*120 8011 O 3 0.015*130 8011 O 4 0.015*150 8011 O ID: 76MM, MAX ROLL WEIGHT: 100 kg 5 0.015*200 8011 O

Aluminum alloy 1350, often referred to as "1350 aluminum foil", is a pure aluminum alloy with a minimum aluminum content of 99.5%. While pure aluminum is not commonly used in pharmaceutical packaging, aluminum and its alloys (including 1350 aluminum) can be used in pharmaceutical packaging after proper processing and coating. Pharmaceutical packaging requires certain properties to ensure the safety and preserv ...