What is aluminum foil for composite foil Aluminum foil for composite foil is an aluminum foil product used to make composite materials. Laminated foils usually consist of two or more layers of films of different materials, at least one of which is aluminum foil. These films can be bonded together using heat and pressure to form composites with multiple functions. Advantages of aluminum foil for composite foil ...

Alloy parameters of aluminum foil for labels Alloy type: 1xxx, 3xxx, 8xxx Thickness: 0.01mm-0.2mm Width: 100mm-800mm Hardness: To ensure the stability and processability of the label. Surface treatment: Coating or painting treatment to improve the corrosion resistance and aesthetics of the label. Alloy type of aluminum foil for labels 1050, 1060, 1100 With high purity ...

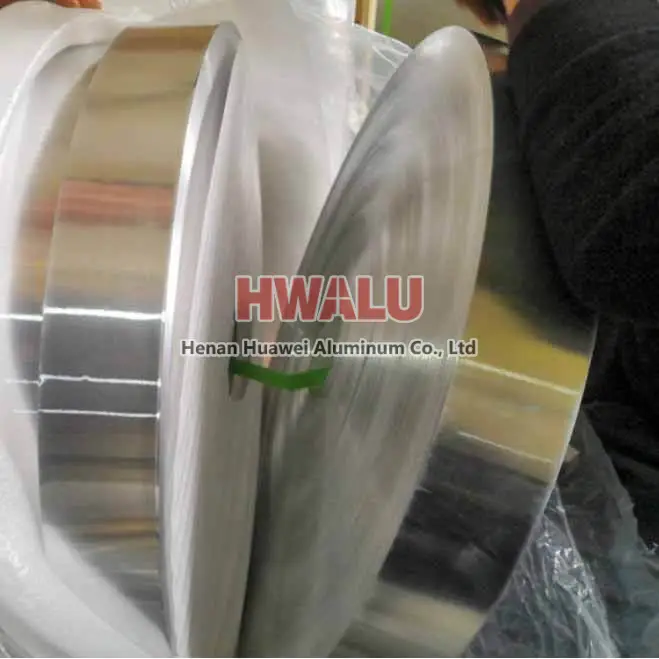

Welcome to Huawei Aluminum, your trusted partner in the world of aluminum foil. We are a leading aluminum foil 8011 12-micron factory and wholesaler, committed to delivering high-quality products that cater to a wide range of industries. In this comprehensive guide, we will explore everything you need to know about our Aluminum Foil 8011, its specifications, and applications. 1. Introduction to Aluminum Foil ...

PTP aluminum Blister foil parameter Alloy 1235, 8011, 8021 etc Temper O( HO ), H18, etc Width 300mm, 600mm, etc Thickness OP: 0.5 - 1.5 g/m2 Aluminum foil: 20 micron ( 0.02mm ), 25 micron ( 0.025mm ), 30 micron ( 0.3mm ) etc HSL ( VC ):3 - 4.5 gsm Primer: 1gsm Surface treatment Laminated, printing, Single bright side, etc What is ptp aluminum blister foil ...

what is Cold forming alu alu foil? Cold forming blister foil can absolutely resist vapor, oxygen and UV rays with good performance of aroma barrier. Each blister is a single protection unit, no effect to barrier after opening first cavity. Cold forming foil is suitable to pack drugs that easy to be affected in wet regions and tropics. It can be shaped in various appearance by changing stamping mold. Simultane ...

After printing and coating, aluminum foil paper and cash register paper need to be post-printed and slit on a slitting machine to cut large rolls of semi-finished products into the required specifications. The semi-finished products that run on the slitting machine are an unwinding and rewinding. This process includes two parts: machine speed control and tension control. The so-called tension is to pull the al ...

What is PE PE refers to polyethylene (Polyethylene), which is a thermoplastic obtained by polymerization of ethylene monomers. Polyethylene has the characteristics of good chemical stability, corrosion resistance, insulation, easy processing and molding, and excellent low-temperature strength. It is a common plastic material widely used in industry and daily life. According to different preparation methods, p ...

Aluminum foil is recyclable. Due to the high purity of aluminum foil materials, they can be reprocessed into various aluminum products after recycling, such as food packaging, construction materials, etc. Recycling aluminum, meanwhile, is an energy-saving process that involves melting down aluminum scrap to create new aluminum products. Compared to producing aluminum from raw materials, the recycling process of a ...

Aluminum foil rolling produces plastic deformation under the conditions of roll-free rolling. At this time, the rolling mill frame is elastically deformed and the rolls are elastically flattened. When the thickness of the rolled piece reaches a smaller and more limited thickness h. When the rolling pressure has no effect, it is very difficult to make the rolled piece thinner. Usually two pieces of aluminum foi ...

▌ Make bananas last longer Like avocados, bananas can go from underripe to overripe in the blink of an eye. This is because bananas release a gas called ethylene to ripen, and the stem is where the most ethylene is released. One way to prevent bananas from ripening too quickly is to wrap a small piece of aluminum foil around the stem. ▌ Polishing chrome with aluminum foil It can be used in places ...

Which 8000 series alloy is more suitable for alu alu foil? For alu alu foil, aluminum foil for pharmaceutical packaging, the selection of the base material needs to take into account factors such as the barrier properties, mechanical strength, processing performance and cost of the aluminum foil. The aluminum foil base material should have excellent moisture barrier, air barrier, light-shielding properties, and ...