Overview of aluminum foil for electronic products As one of the core materials of electronic devices, aluminum foil for electronic products has always been the focus of electrical appliance manufacturers. As a term that doesn't come up very often, you might have questions about it. What is aluminum foil for electronic products? What are the classifications of aluminum foil for electronic products? What are the a ...

What is aluminum foil for food Aluminum foil for food is a type of aluminum foil that is specifically designed and manufactured for use in food preparation, cooking, storage, and transport. It is commonly used in households and food service industries to wrap, cover, and store food items, as well as to line baking sheets and pans. Aluminum foil for food is available in various sizes, thicknesses, and strength ...

What is aluminum foil for sealing Aluminum foil for sealing is a kind of aluminum foil used for sealing packaging. It is usually composed of aluminum foil and plastic film and other materials, and has good sealing performance and fresh-keeping performance. Aluminum foil for sealing is widely used in the packaging of food, medicine, cosmetics, medical equipment and other industries. Aluminum foil for sealing i ...

so What is Aluminum foil grade 1235? 1235 Alloy Aluminum Foil is an aluminum alloy material commonly used in the packaging industry. It is as high as 99.35% pure, has good flexibility and ductility, and also has good electrical and thermal conductivity. The surface is coated or painted to increase its resistance to corrosion and abrasion. 1235 Alloy Aluminum Foil is widely used in food packaging, pharmaceu ...

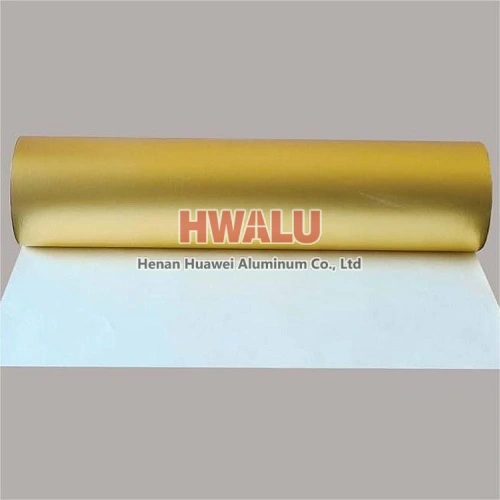

Gold aluminum foil roll The color of aluminum foil itself is silver-white, and gold aluminum foil refers to aluminum flakes that have a golden surface after being coated or treated. Aluminum foil gold can give a very good visual appearance. This type of foil is often used for decorative purposes, arts and crafts and various packaging applications that require a metallic gold appearance. Heavy duty gold alum ...

Aluminum foil is a thin sheet of aluminum metal that has the following properties: Lightweight: Aluminum foil is very lightweight because aluminium metal itself is a lightweight material. This makes aluminum foil an ideal material during packaging and shipping. Good sealing: The surface of aluminum foil is very smooth, which can effectively prevent the penetration of oxygen, water vapor and other gases, s ...

Degreasing pollution is mainly manifested on the surface of the aluminum foil in 0 state. After the aluminum foil is annealed, it is tested by the water brushing method, and it does not reach the level specified in the water brushing test. The aluminum foil that requires the water-washing test is mainly used for printing, composite with other materials, etc. Therefore, the surface of the aluminum foil must be ...

Oven bottom: Do not spread aluminum foil on the bottom of the oven. This could cause the oven to overheat and cause a fire. Use with acidic foods: Aluminum foil should not come in contact with acidic foods such as lemons, tomatoes, or other acidic foods. These foods can dissolve the aluminum foil, increasing the aluminum content of the food. Bake Clean Oven Racks: Aluminum foil should not be used to cov ...

As the name suggests, an air fryer is a machine that uses air to "fry" food. It by using the principle of high-speed air circulation, mainly through the heating tube to heat the air, and then the fan will air into high-speed circulation heat flow, when the food is heating, hot air convection can make food fast dehydration, the oil of baking food itself, in the end, become golden crispy food surface, appear simila ...

The performance differences between 3003 aluminum foil and aluminum plate are primarily related to its physical and mechanical properties and its intended application. Here are some of the main differences in performance: Formability: 3003 Aluminum Foil: 3003 aluminum foil is highly formable and can be bent, formed and folded easily. It is often used in applications that require flexibility and ease of mold ...

It is a characteristic of aluminum box rolling that the thickness deviation is difficult to control. The thickness difference of 3% is not difficult to control in the production of plate and strip, but it is more difficult to control in the production of aluminum foil. As the thickness of the aluminum box becomes thinner, its micro-conditions can affect it, such as temperature, oil film, and oil and gas concen ...