What is a lidding foil? Lidding foil, also known as lid foil or lid, is a thin sheet of aluminum or composite material used to seal containers such as cups, jars, and trays to protect the contents inside. Lidding foils come in a variety of shapes, sizes, and designs to suit different types of containers and packaging applications. They can be printed with branding, logos, and product information to enhance a ...

Custom printing aluminum foil jumbo roll The printing process and precautions of aluminum foil for medicine packs The process flow of packaging aluminum foil is: aluminum foil unwinding -> gravure printing -> drying -> protective layer coating -> drying -> adhesive layer coating -> drying -> aluminum foil winding. In order to achieve the above-mentioned performance requirements in the PTP ...

what is Cold forming alu alu foil? Cold forming blister foil can absolutely resist vapor, oxygen and UV rays with good performance of aroma barrier. Each blister is a single protection unit, no effect to barrier after opening first cavity. Cold forming foil is suitable to pack drugs that easy to be affected in wet regions and tropics. It can be shaped in various appearance by changing stamping mold. Simultane ...

Alloy type of aluminum foil for cosmetics 8011 aluminum foil 8021 alloy aluminum foil 8079 aluminum foil alloy Where is aluminum foil for cosmetics used in cosmetics? 1-Packaging: Some products in cosmetics, such as facial masks, eye masks, lip masks, patches, etc., usually use aluminum foil packaging, because aluminum foil has good moisture-proof, anti-oxidation, heat insulation, fresh-keeping and ...

Introduction of 8011 alloy aluminum foil 8011 alloy aluminum foil is added Al-Fe-Si elements, more than 1% of the total alloying elements in the corresponding performance of its alloy has a higher advantage, mainly for food packaging, and pharmaceutical packaging. Machinable range of thickness: 0.02mm-0.07mm, width 300mm-1100mm, can be customized according to customer needs. General parameters of aluminu ...

8006 aluminum foil is mainly used for food packaging, such as milk boxes, juice boxes, etc. 8006 aluminum foil has good corrosion resistance and mechanical properties, which can meet various packaging needs. 8011 aluminum foil is a common aluminum alloy material, mainly used in food packaging and pharmaceutical packaging. 8011 aluminum foil has good waterproof, moisture-proof and oxidation-proof properties, an ...

Fire or explosion in aluminum foil rolling must meet three conditions: combustible materials, such as rolling oil, cotton yarn, hose, etc.; combustible materials, that is, oxygen in the air; fire source and high temperature, such as friction, electric sparks, static electricity, open flames, etc. . Without one of these conditions, it will not burn and explode. The oil vapor and oxygen in the air generated duri ...

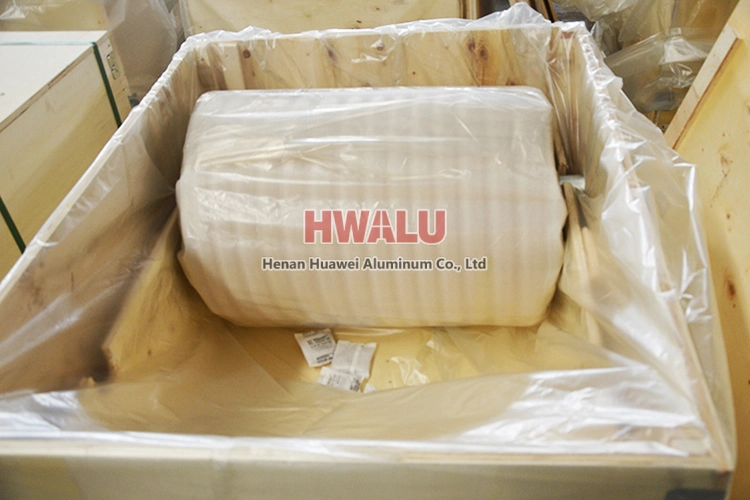

hot ingot rolling First, the aluminum melt is cast into a slab, and after homogenization, hot rolling, cold rolling, intermediate annealing and other processes, it is continued to be cold rolled into a sheet with a thickness of about 0.4~1.0 mm as a foil blank (casting → hot rolling billet → cold rolling → foil rolling). In the ingot hot rolling method, the hot rolled billet is first milled to remove defect ...

Product name: plain aluminum foil SIZE (MM) ALLOY / TEMPER 0.1MM*1220MM*200M 8011 O

The aluminum foil disposable lunch box has excellent oil and water resistance and is easy to recycle after being discarded. This kind of packaging can quickly reheat the food and keep the fresh taste of the food. 1. Performance of aluminum foil tableware and containers: All kinds of food lunch boxes produced by aluminum foil, aviation lunch boxes currently generally adopt the latest and most scientific alum ...

The rolling oil and other oil stains remaining on the surface of the foil, which are formed on the foil surface to varying degrees after annealing, are called oil spots. The main reasons for oil spots: high degree of oil in aluminum foil rolling, or inappropriate distillation range of rolling oil; mechanical oil infiltration in aluminum foil rolling oil; improper annealing process; excessive oil on the surface ...