what is 1145 alloy aluminum foil? 1145 alloy aluminum foil and its sister alloy 1235 have a minimum aluminum content of 99.45%, and the chemical and physical properties are almost the same. Occasionally, some production batches can be double-certified for 1145 and 1235 alloys. Like 1100 aluminum alloys, both are considered commercially pure alloys with excellent formability. Due to the high aluminum content, ...

What is 5052 alloy aluminum foil? 5052 aluminum foil is a common aluminum alloy material, which is composed of aluminum, magnesium and other elements, and has the characteristics of medium strength, good corrosion resistance and weldability. It is a common aluminum alloy material for industrial use, usually used in the production of fuel tanks, fuel pipelines, aircraft parts, auto parts, building panels, etc. 5 ...

Basic parameters of aluminum foil for food packaging Thickness: 0.006-0.2mm Width: 20-1600mm Material state: O, H14, H16, H18, etc. Fields of application: packaged cooked food, marinated products, bean products, candy, chocolate, etc. What properties does aluminum foil use for food packaging bags? Foil has outstanding properties of impermeability (especially for oxygen and water vapor) and shading, an ...

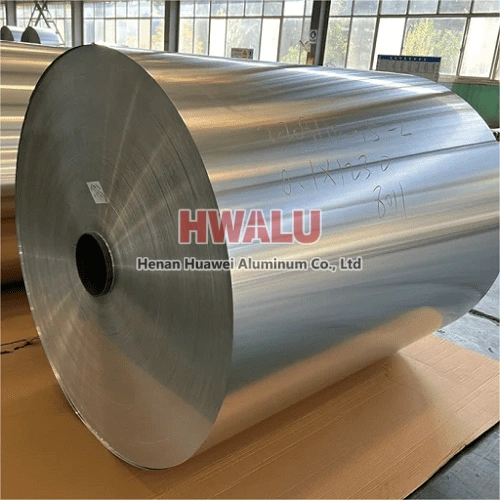

Baking food aluminum foil roll Aluminum foil is a product with a very wide range of uses. According to the use of aluminum foil, it can be divided into industrial aluminum foil and domestic aluminum foil. Baking food aluminum foil roll is aluminum foil for daily use. Aluminum foil is widely used in daily life, such as the production of aluminum foil lunch boxes, food packaging, pharmaceutical packaging, etc. ...

What is aluminium foil 11 micron? 11 micron aluminum foil refers to a thin sheet of aluminum that is approximately 11 microns (μm) thick. The term "micron" is a unit of length equal to one millionth of a meter. Aluminum foil 11 micron, also known as 0.0011mm aluminum foil, is a multifunctional material with excellent barrier properties, flexibility and conductivity. Aluminum foil thickness application Aluminu ...

1. The raw materials are non-toxic and the quality is safe Aluminum foil is made of primary aluminum alloy after rolling through multiple processes, and it has no harmful substances such as heavy metals. In the aluminum foil production process, a high-temperature annealing and disinfection process is used. Therefore, the aluminum foil can be safely in contact with food and will not contain or help the growth o ...

Aluminum foil lunch boxes made of aluminum foil can be processed into various shapes and are widely used in food packaging such as pastry baking, airline catering, takeaway, cooked food, instant noodles, instant lunch and other food fields. The aluminum foil lunch box has a clean appearance and good thermal conductivity. It can be heated directly on the original packaging with ovens, microwave ovens, steamers and ...

Aluminum foil lunch box is a new type of non-toxic and environmentally friendly tableware. 1. The main ingredient in the aluminum foil lunch box is aluminum, so it will react with acid like aluminum cans, and the salt produced by aluminum and organic acids will react with gastric acid to produce aluminum chloride, so we need to use it. Note that, generally speaking, it is often used for steaming rice. There is ...

The main factors affecting the heat sealing strength of aluminum foil medicine packaging are as follows: 1. Raw and auxiliary materials The original aluminum foil is the carrier of the adhesive layer, and its quality has a great influence on the heat seal strength of the product. In particular, oil stains on the surface of the original aluminum foil will weaken the adhesion between the adhesive and the orig ...

In the production process of aluminum foil, there are multiple processes such as rolling, finishing, annealing, packaging, etc. The interlocking production process, any problem in any link may cause aluminum foil quality problems. The quality defects of the purchased aluminum foil products will not only affect the appearance, but also directly affect the quality of the products produced, and even more directly ca ...

1. Insulation and fragrance preservation Aluminum foil lunch boxes are usually used as paper-wrapped beverage packaging. The thickness of the aluminum foil in the packaging bag is only 6.5 microns. This thin aluminum layer can be waterproof, preserve umami, anti-bacterial and anti-fouling. The characteristics of preservation of fragrance and freshness make the aluminum foil lunch box possess the properties of fo ...