What is Aluminum Foil Tape? Aluminum foil tape is a tape based on aluminum foil, which is divided into the single-sided tape and double-sided tape; it can also be divided into conductive tape and non-conductive tape; conductive tape can also be divided into the unidirectional conductive tape and anisotropic conductive tape; It is divided into ordinary aluminum foil tape and high-temperature resistant aluminum fo ...

What is aluminum foil for induction Aluminum foil for induction is a special aluminium foil material with the function of electromagnetic induction heating. It is commonly used to seal the lids of bottles, jars or other containers for sterile, airtight packaging. In addition, aluminium foil for sensing also has the advantages of easy operation, high efficiency and environmental protection. The working princi ...

Aluminum foil for capacitor parameters Alloy Temper Thickness Width Core inner diameter Maximum outer diameter of aluminum coil Thickness tolerance Wettability Brightness L Aluminum foil for capacitors 1235 0 0.005-0.016mm 100-500mm 76 500 ≦5 Class A (Brush water test) ≦60 aluminum foil capacitor The aluminum foil used in electrolytic capacitors is a corrosive material that wor ...

Aluminum foil supplier for India Huawei Aluminum Foil Factory exports a large amount of aluminum foil products to India every year, and we are able to provide aluminum foil products for a variety of application types. What types of aluminum foil are classified according to application? Aluminum foil comes in various types, and its classification often depends on the specific application for which it is int ...

What is aluminum foil for pharmaceutical packaging Aluminum foil for pharmaceutical packaging is usually composed of aluminum foil, plastic film, and a glue layer. Aluminium foil has many advantages as a packaging material, such as moisture-proof, anti-oxidation and anti-ultraviolet properties, and can effectively protect medicines from light, oxygen, and moisture. Aluminium foil for pharmaceutical packaging ...

Soft Temper Jumbo Aluminum Foil Roll Introduction Welcome to Huawei Aluminum, your trusted partner in the world of aluminum foil solutions. As a leading factory and wholesaler, we take pride in offering premium Soft Temper Jumbo Aluminum Foil Rolls that cater to a diverse range of industries and applications. With a commitment to quality and excellence, Huawei Aluminum stands as a beacon of reliability in the al ...

Single-sided carbon-coated aluminum foil is a breakthrough technological innovation that uses functional coatings to treat the surface of battery conductive substrates. Carbon-coated aluminum foil/copper foil is to uniformly and finely coat dispersed nano-conductive graphite and carbon-coated particles on aluminum foil/copper foil. It can provide excellent electrostatic conductivity, collect the micro-current ...

1. Chemical composition: The alloy grades of aluminum foil for heat exchange fins mainly include 1100, 1200, 8011, 8006, etc. From the perspective of use, air conditioners do not have strict requirements on the chemical composition of aluminum heat exchange fins. Without surface treatment, 3A21 aluminum alloy has relatively good corrosion resistance, high mechanical properties such as strength and elongation, ...

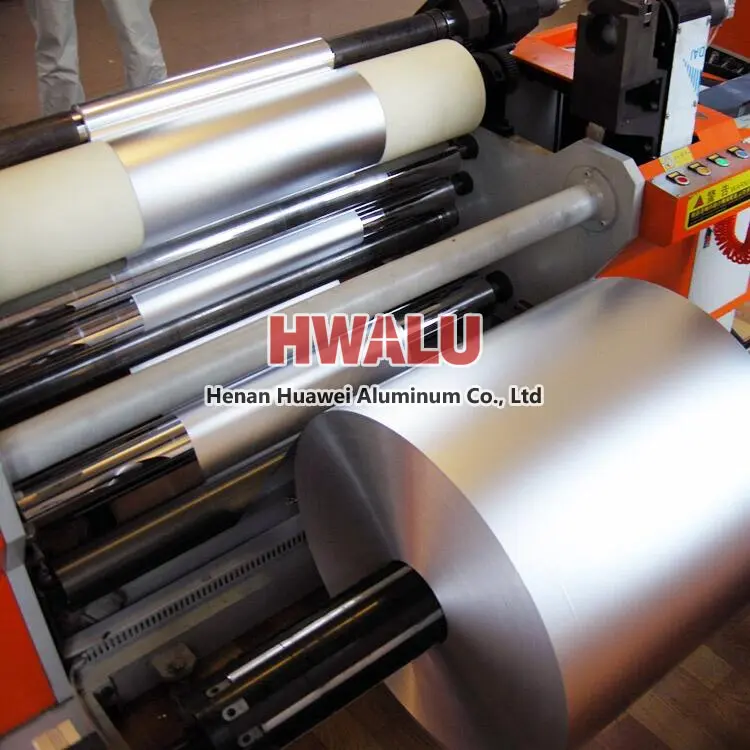

Cast-rolled aluminum foil production process Aluminum liquid, aluminum ingot -> Smelt -> Continuous roll casting -> Winding -> Cast roll finished product Plain foil production process Plain foil -> Cast-rolled coil -> Cold rolled -> Foil rolling -> Slitting -> Annealing -> Plain foil finished product The manufacture of aluminum foil is similar to making pasta at home. A large b ...

Common aluminum foil materials are 8011 aluminum foil and 1235 aluminum foil. The alloys are different. What's the difference? Aluminum foil 1235 aluminum foil is different from 8011 aluminum foil alloy. The process difference lies in the annealing temperature. The annealing temperature of 1235 aluminum foil is lower than that of 8011 aluminum foil, but the annealing time is basically the same. 8011 aluminum foi ...

After printing and coating, aluminum foil paper and cash register paper need to be post-printed and slit on a slitting machine to cut large rolls of semi-finished products into the required specifications. The semi-finished products that run on the slitting machine are an unwinding and rewinding. This process includes two parts: machine speed control and tension control. The so-called tension is to pull the al ...

hot ingot rolling First, the aluminum melt is cast into a slab, and after homogenization, hot rolling, cold rolling, intermediate annealing and other processes, it is continued to be cold rolled into a sheet with a thickness of about 0.4~1.0 mm as a foil blank (casting → hot rolling billet → cold rolling → foil rolling). In the ingot hot rolling method, the hot rolled billet is first milled to remove defect ...