What is Extra-heavy duty aluminum foil Extra-heavy duty aluminum foil is a type of aluminum foil that is thicker and more durable than standard or heavy-duty aluminum foil. It is designed to withstand higher temperatures and provide extra strength, making it suitable for more demanding applications in the kitchen and beyond. Extra-heavy duty aluminum foil common alloys The common alloy used for extra-heavy ...

What is aluminum foil for hookah Aluminum foil for hookah is a type of aluminum foil that is specifically designed and marketed for use in hookahs or water pipes. It is commonly used to cover the bowl of the hookah and hold the tobacco or shisha that is smoked through the pipe. Hookah foil is typically thinner than other types of aluminum foil, making it more pliable and easier to fit over the hookah bowl. It ...

Introduction of 8006 alloy aluminum foil 8006 alloy aluminum foil is a non-heat treatable aluminum alloy. The 8006 aluminum foil product has a bright surface and is degreasing clean. Especially suitable for making wrinkle-free lunch boxes. Huawei Aluminum's 8006 aluminum foil adopts hot rolling method, and the tensile strength is between 123-135Mpa. Technical parameters of aluminum foil 8006 Alloy 8 ...

Basic parameters of aluminum foil for food packaging Thickness: 0.006-0.2mm Width: 20-1600mm Material state: O, H14, H16, H18, etc. Fields of application: packaged cooked food, marinated products, bean products, candy, chocolate, etc. What properties does aluminum foil use for food packaging bags? Foil has outstanding properties of impermeability (especially for oxygen and water vapor) and shading, an ...

Aluminum foil for kitchen parameters Surface Teatment: One side bright, another side dull. Printing: coloured gold, rose gold Embossed: 3d pattern Thickness: 20mts, 10 mic, 15 micron etc Sizes: 1m, 40*600cm, 40x100 cm etc Characteristics and uses of kitchen aluminum foil Aluminum foil is a versatile and commonly used kitchen item that offers a range of benefits for cooking, food storage and othe ...

Aluminum foil lunch box is a new type of non-toxic and environmentally friendly tableware. 1. The main ingredient in the aluminum foil lunch box is aluminum, so it will react with acid like aluminum cans, and the salt produced by aluminum and organic acids will react with gastric acid to produce aluminum chloride, so we need to use it. Note that, generally speaking, it is often used for steaming rice. There is ...

Product name: 8011 aluminum foil roll ID: 76MM, MAX ROLL WEIGHT: 55kg ITEM SPECIFICATION (MM) ALLOY / TEMPER 1 0.015*120 8011 O 2 0.012*120 8011 O 3 0.015*130 8011 O 4 0.015*150 8011 O ID: 76MM, MAX ROLL WEIGHT: 100 kg 5 0.015*200 8011 O

Common aluminum foil materials are 8011 aluminum foil and 1235 aluminum foil. The alloys are different. What's the difference? Aluminum foil 1235 aluminum foil is different from 8011 aluminum foil alloy. The process difference lies in the annealing temperature. The annealing temperature of 1235 aluminum foil is lower than that of 8011 aluminum foil, but the annealing time is basically the same. 8011 aluminum foi ...

1. Uncoated aluminum foil Uncoated aluminum foil refers to aluminum foil that has been rolled and annealed without any form of surface treatment. In my country 10 years ago, the aluminum foil used for air-conditioning heat exchangers in foreign countries about 15 years ago was all uncoated aluminum foil. Even at present, about 50% of the heat exchange fins used in foreign developed countries are still uncoated ...

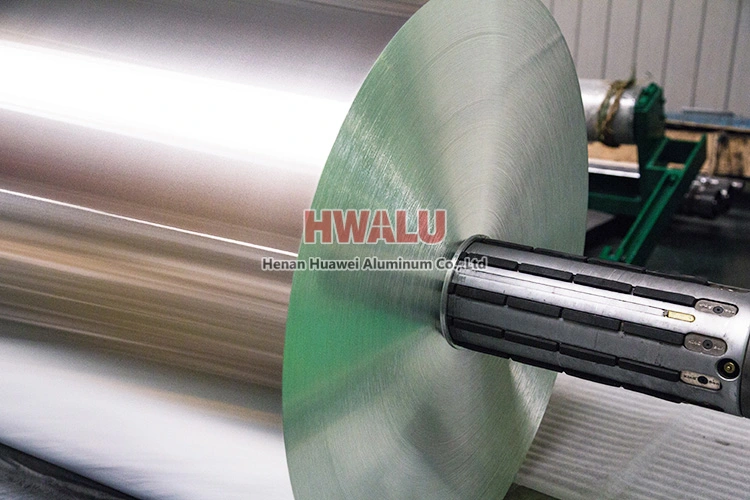

In recent years, Huawei Aluminum Co., Ltd. has set up a special research team under the condition that the aluminum foil rolling mill backing roll and the inner ring of the backing roll bearing are tight, to maintain production by repairing the scrapped backing rolls, and to ensure the normal operation of the seven aluminum foil rolling mills. During the repair process, the research team was able to repair, explo ...

Aluminum alloy 1350, often referred to as "1350 aluminum foil", is a pure aluminum alloy with a minimum aluminum content of 99.5%. While pure aluminum is not commonly used in pharmaceutical packaging, aluminum and its alloys (including 1350 aluminum) can be used in pharmaceutical packaging after proper processing and coating. Pharmaceutical packaging requires certain properties to ensure the safety and preserv ...