Alloy parameters of aluminum foil for chocolate packaging Chocolate packaging aluminum foil is usually composed of aluminum and other alloying elements to increase its strength and corrosion resistance. Alloy series 1000, 3000, 8000 series aluminum alloy Alloy state H18 or H19 hardened state Alloy composition pure aluminum containing more than 99% aluminum, and other elements such as silicon, ...

What is aluminum foil for foil board Aluminum foil for foil board refers to a special type of aluminum foil used to make foil board, also known as "foil material". Foil sheets are commonly used to package food and pharmaceuticals to protect them from air, moisture, odours, light and other external elements. Aluminum foil for foil boards is usually thicker than regular aluminum foil, usually between 0.2-0.3 mm ...

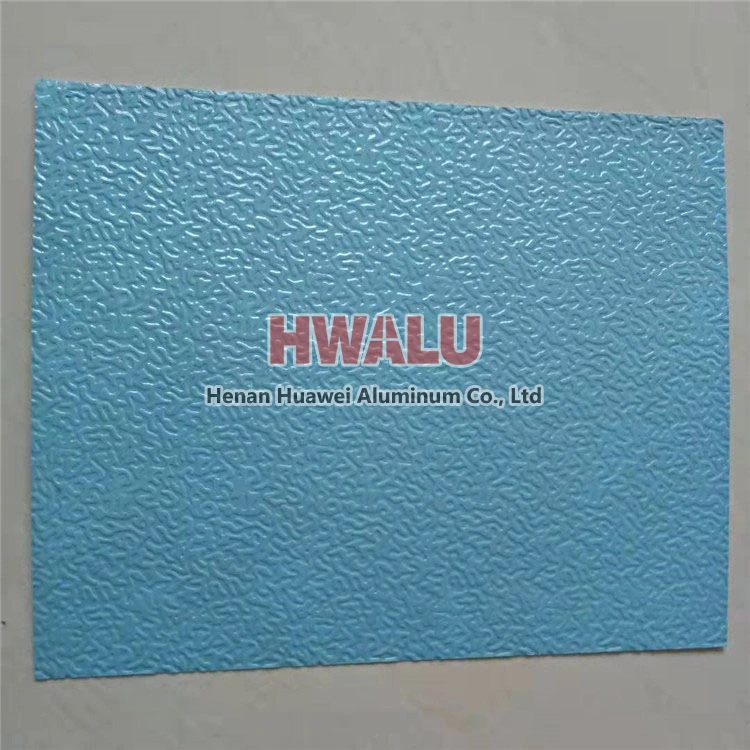

Specifications of sarin coated embossed aluminum foil Alloy model 1100 or 1200 3003 or 3004 5052, 5083, 5754 8011, 8079 Thickness 0.006mm-0.2mm Width 200mm-1600mm Flower type Common flower types include five flowers, tiger skin, pearl and so on. Coating sarin coating, color: gold, silver, red, green, blue, etc. Paper core inner diameter 76mm or 152mm Packing method w ...

What is AC aluminum foil? Air conditioning aluminum foil, often called AC foil or HVAC foil, is a type of aluminum foil used in the heating, ventilation and air conditioning (HVAC) industry. Air-conditioning aluminum foil is usually used to make heat-conducting fins for air-conditioning heat exchange and air-conditioning evaporators. It is one of the important alloys used in air conditioning manufacturing raw ma ...

What Is Food Packaging Aluminium Foil Roll 8011 As we all know, aluminum foil is widely used in our daily life, especially in the field of food packaging. Aluminum foil roll 8011 is a common food packaging material. 8011 aluminum alloy is a high-quality aluminum alloy with good ductility, strength and corrosion resistance. This type of aluminum foil is commonly used for food packaging. 8011 aluminum fo ...

The performance differences between 3003 aluminum foil and aluminum plate are primarily related to its physical and mechanical properties and its intended application. Here are some of the main differences in performance: Formability: 3003 Aluminum Foil: 3003 aluminum foil is highly formable and can be bent, formed and folded easily. It is often used in applications that require flexibility and ease of mold ...

Coated aluminum foil is formed after surface treatment on the basis of non-coated aluminum foil. In addition to the chemical composition, mechanical properties and geometric dimensions required by the above non-coated aluminum foil, it should also have good shape and shape. coating properties. 1. Plate type of aluminum foil: First of all, the production process of coated aluminum foil requires that the alum ...

Have you ever eaten grilled fish or sixty-six, and you must have seen this tin foil, but have you seen this thing used in indoor spaces? That's right it's called decorative foil (decorative tin foil). Generally, it can be used on walls, top cabinets, or art installations. Aluminum foil (tinfoil paper) can be kneaded out of wrinkles, resulting in a very unique and abstract reflective texture, and the appeara ...

It is generally believed that the single-sheet rolling speed of the aluminum foil should reach 80% of the rolling design speed of the rolling mill. Danyang Aluminum Company introduced a 1500 mm four-high irreversible aluminum foil roughing mill from Germany ACIIENACH. The design speed is 2 000 m/min. At present, the single-sheet aluminum foil rolling speed is basically at the level of 600m/miT, and the domestic s ...

The biggest feature of aluminum foil is its light weight and wide range of uses, suitable for aviation, construction, decoration, industry and other industries. Aluminum is very cost-effective, and its electrical conductivity is second only to that of copper, but the price is much cheaper than that of copper, so many people now choose aluminum as the main material for wires. 1060, 3003, 5052 are several common ...

Only China, the United States, Japan and Germany can produce double zero foils with a thickness of 0.0046mm in the world. From a technical point of view, it is not difficult to produce such thin foils, but it is not easy to efficiently produce high-quality double-zero foils on a large scale. At present, many enterprises in my country can realize the commercial production of double zero foil, mainly including: ...